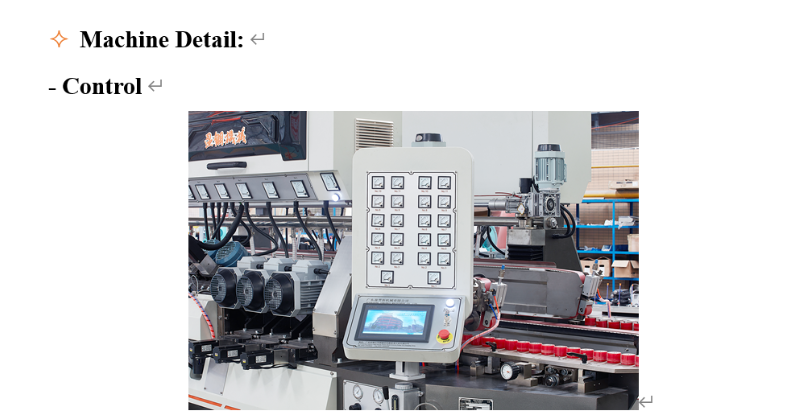

The glass double side polisher using PLC +Touchscreen with centralized-control system. The operator canmonitor the current of each motor by control center, Please check the red circle with currentmeter, You can check the situation of motor by both of them, double-monitor system.<

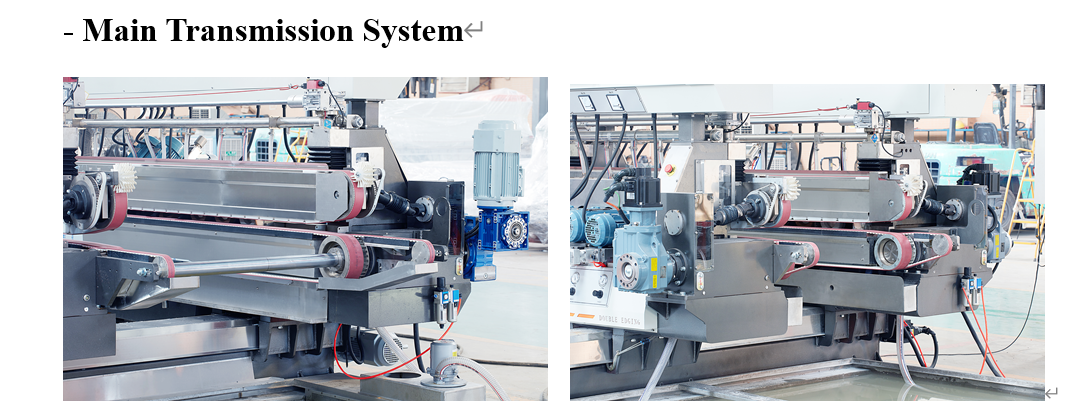

- The glass double side polisher main gear box shaft sleeve adopts through sleeve structure, using high precision roller bearings, stable and reliable operation, long service life, reduce maintenance cost. Servo motor transmission is also available for option.

1. Glass double side polisher Motor configuration:

- Conveyor motor: variable frequency motor 2.2KW

- Roller conveyor motor 1: variable frequency motor 1.5KW

- Roller conveyor motor 2: variable frequency motor 1.5KW

2. Technical parameters:

1 | Minimum size of the transfer glass: | 350mm * 350mm |

2 | Maximum size of the transfer glass | 2500mm * 1500mm |

3 | Thickness of the transfer glass | 3-25mm |

4 | Total power | 5.2KW |

5 | Dimensions | 8100mm * 2900mm * 1000mm |

Remark: When the size of the transfer glass changes, the external dimensions change accordingly. | ||

Main body of the glass double processing machine

Base of glass double processing machine

The Automatic Floating Polish Edger base is mechanically reinforced with triangular beams. The high quality national standard square pipe is processed by CNC machining center to ensure the stability and machining accuracy of the machine.

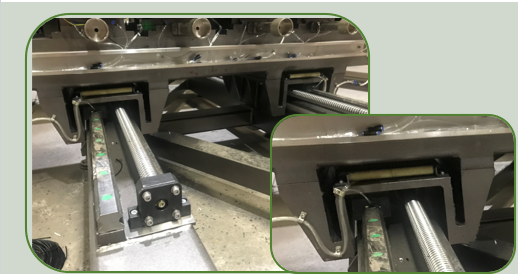

Supporting frame

glass double processing machine can achieve bidirectional balance, to reduce the lateral force of ball screw and linear guide rail.

It has good deformation resistance, maintain the machining accuracy of the machine and extend the service life of the machine.

Beam

Automatic Floating Polish Edger Beams are deeply machined by our own CNC machining center with an accuracy of 0.02mm, and are one-shot machined in paired boxes to ensure smooth and accurate glass transfer.