Applications of ENKONGS Glass Double Edger Machine

The Glass Double Edger Machine is used in various industries that require high-quality glass products with precise, uniform edges. Some of the most common applications include:

Architectural Glass: In the construction industry, the Glass Double Edger Machine is used to process glass panels for windows, facades, and doors. The smooth, polished edges produced by the machine ensure that the glass fits perfectly into architectural designs while enhancing the visual appeal of the building.

Home Appliance Glass: The Home Appliance Glass Double Edging Machine is used to process glass components for refrigerators, washing machines, and ovens. The precise edge finishing ensures that the glass is safe to handle, meets safety standards, and contributes to the overall aesthetics of the appliance.

Furniture Glass: The Glass Double Pencil Edging Machine is widely used in the furniture industry to produce glass tabletops, shelves, and display cases. Pencil-edged glass is both functional and aesthetically pleasing, making it a popular choice for home décor and commercial furniture.

Automotive Glass: The Glass Double Edger Machine is used in the automotive industry to process windows, windshields, and mirrors. The machine ensures that the edges of automotive glass are smooth and free of sharp points, enhancing both safety and visual appeal.

Decorative Glass: In the production of decorative glass products, such as mirrors and art glass, the Glass Double Edger Machine provides the precise edge finishing required for high-quality results. The machine can produce a variety of edge profiles, making it suitable for custom glass designs.

Laminated and Tempered Glass: The Glass Double Edger Machine is capable of processing laminated and tempered glass, ensuring that the edges are smooth, polished, and consistent. This is particularly important in industries where the glass must meet safety standards and be resistant to breakage.

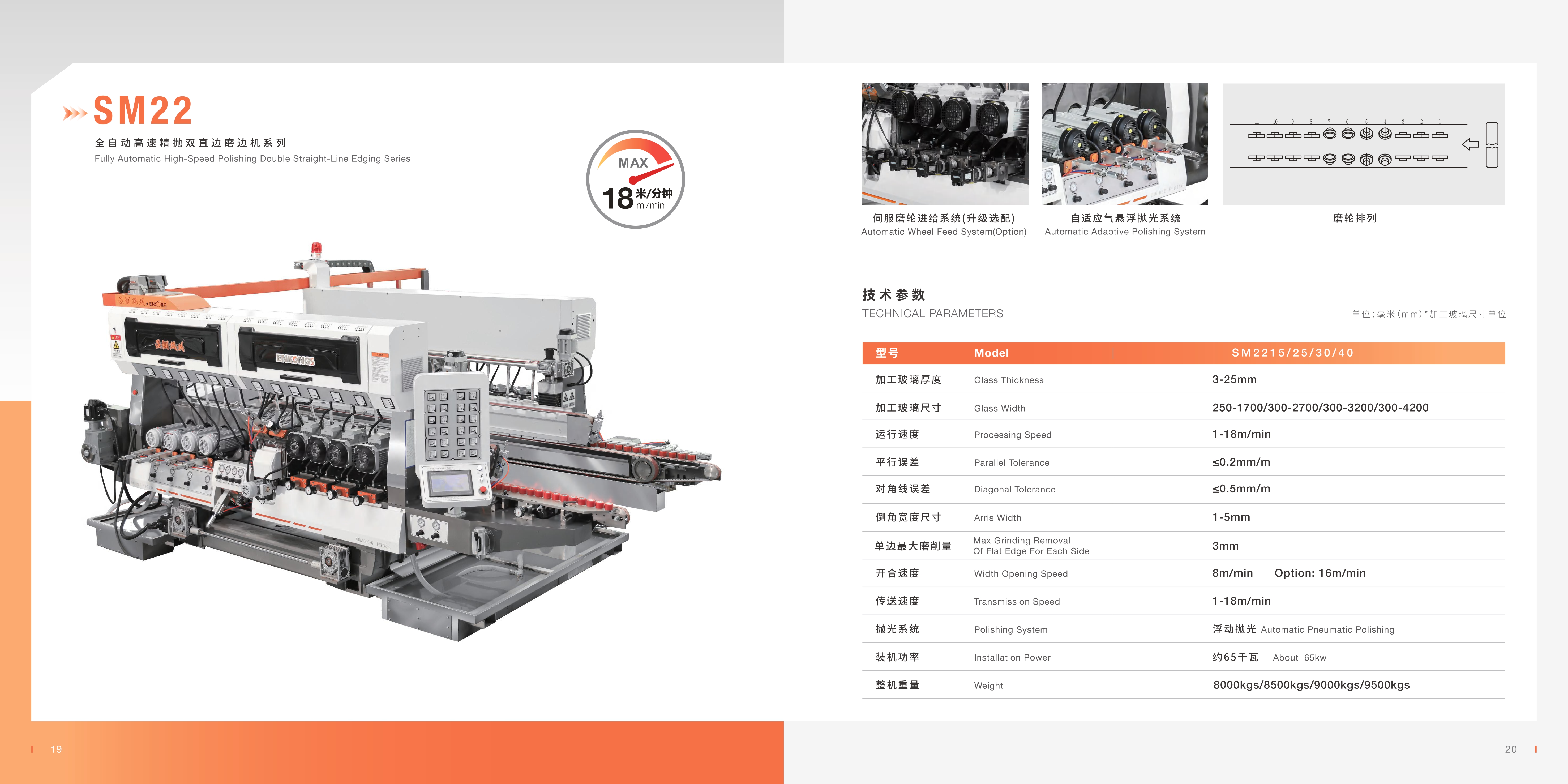

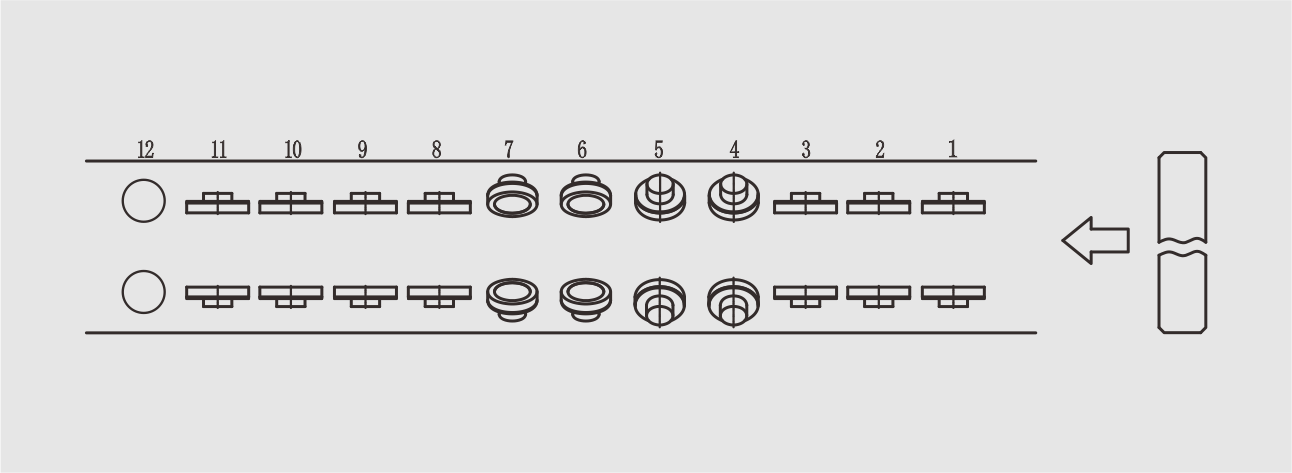

Double-Sided Edging: Specialized machinery for simultaneous double-sided edging of glass panels, ensuring uniform thickness and smooth edges with high precision.

Advanced Grinding Mechanism: Equipped with precision grinding wheels and powerful motors, the SM24 achieves consistent and uniform edging results with minimal tolerance.

Adjustable Parameters: Offers flexibility to adjust edging parameters such as speed, angle, and thickness to accommodate various glass specifications and processing requirements.

User-Friendly Interface: Features an intuitive control panel with easy-to-use controls for seamless operation and monitoring of machine functions.

High Efficiency: Designed for high-speed processing, the SM24 maximizes productivity while maintaining uncompromising quality and precision in glass edging operations.

Durable Construction: Constructed with high-quality materials and precision-engineered components for durability and reliability in demanding industrial environments.

The Glass Double Edger Machine provides excellent precision and flexibility for edge finishing. Double side glass processing machine is equipped with adjustable spindles and various grinding heads, which allow the operator to modify the machine’s settings based on the thickness, size, and type of glass being processed. This flexibility makes the machine ideal for handling different types of glass, from clear glass to frosted, laminated, or tempered glass.

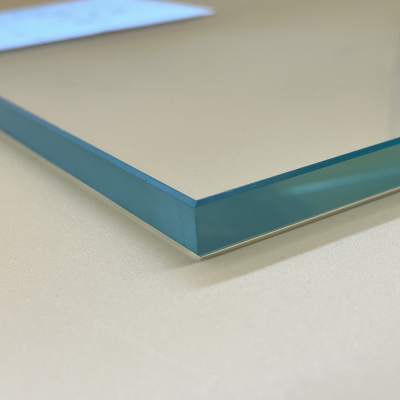

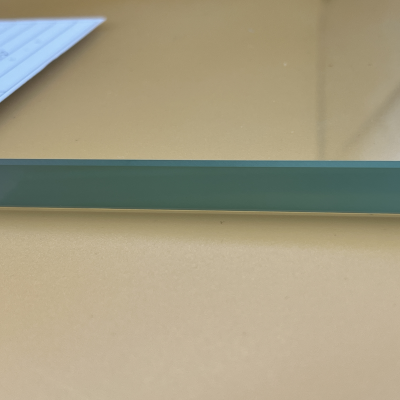

In addition to its flexibility, the Glass Double Edger Machine is known for its precision. The machine is capable of producing uniform, clean, and smooth edges, which is essential in industries such as automotive glass, architectural glass, and decorative glass production. The precise edge treatment ensures that the glass products meet stringent quality standards, reducing the likelihood of defects or inconsistencies.

Enkongs' SM24:

As a manufacturer of Glass Double Edger Machines, we take pride in providing high-quality equipment that meets the needs of glass manufacturers and processors. Enkongs Glass Double Edger Machines offer several advantages and are designed for a variety of applications in the glass industry.

One of the key advantages of Enkongs Glass Double Edger Machines is their efficiency and precision. Equipped with two grinding heads that work simultaneously, our machines can grind both edges of a glass panel at the same time, increasing productivity and ensuring consistent quality. The diamond grinding wheels used in enkongs machines are capable of achieving a high level of precision, resulting in smooth and uniform edges on glass panels.

ENKONGS' SM24 Glass Double Edger Machines are versatile and can handle glass panels of different thicknesses, making them suitable for a wide range of applications in the glass industry. Whether it's glass doors, windows, mirrors, or other glass products, our machines can provide the edge finishing needed to meet the highest standards of quality.

In addition to grinding, enkongs Glass Double Edger Machines also have polishing capabilities. After the edges are ground, our machines can polish the glass to achieve a shiny and smooth finish, enhancing the aesthetic appeal of the glass and improving its durability and resistance to scratches.

Overall, Enkongs Glass Double Edger Machines are essential tools for glass manufacturers and processors looking to achieve high-quality edge finishing on glass panels. With their efficiency, precision, and versatility, our machines are designed to meet the diverse needs of the glass industry and help Enkongs customers produce top-quality glass products.