Technical Data:

Number of Spindles: 24

Max. glass dimension: Up to 4200(option: Jumbo Glass Size can be customize)

Min. glass size: 300x300 (option: 250x250)

Glass thickness: 3~25 mm

Working Speed: 1-15m/min

Width adjustment Speed: 4m/min (optional:8m/min)

Max. edge grinding: 3mm

Tolerance of the diagonal(1000x1000): ±0.5mm

Tolerance on the parallelism(mm): ±0.2mm

Arris width:1-5mm

Total power: about 65KW

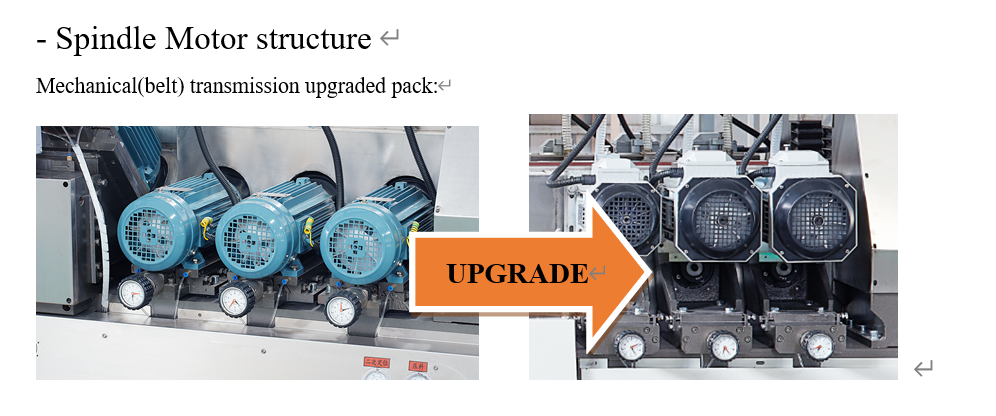

1. Standard Model: High performance ABB motors first one adopts 3kw. Inside of the sliding part adopt the bronze nut work with adjustment screw rod to reduce the gap, more flexible and durable.

2. Mechanical (belt) transmission: with 4200rpm mechanical transmission by belt driven. Spindles shaft rotation at 4200rpm/min. The shaft can tolerant up to 12000rpm/min maximum, however, only using 1/3 of total speed capacity. The processing speed is upon 15m/min with polishing. Grinding ability has improved

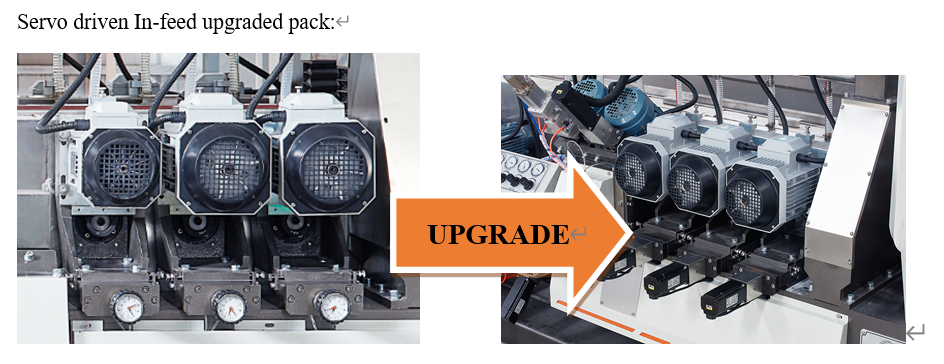

3. Mechanical (belt) transmission with Servo driven In-feed arrangement: Fully automatic wheel adjustment. Precise calculation between wheel and material. Avoiding uneven grinding caused by human error. Stepping into the next automation level.

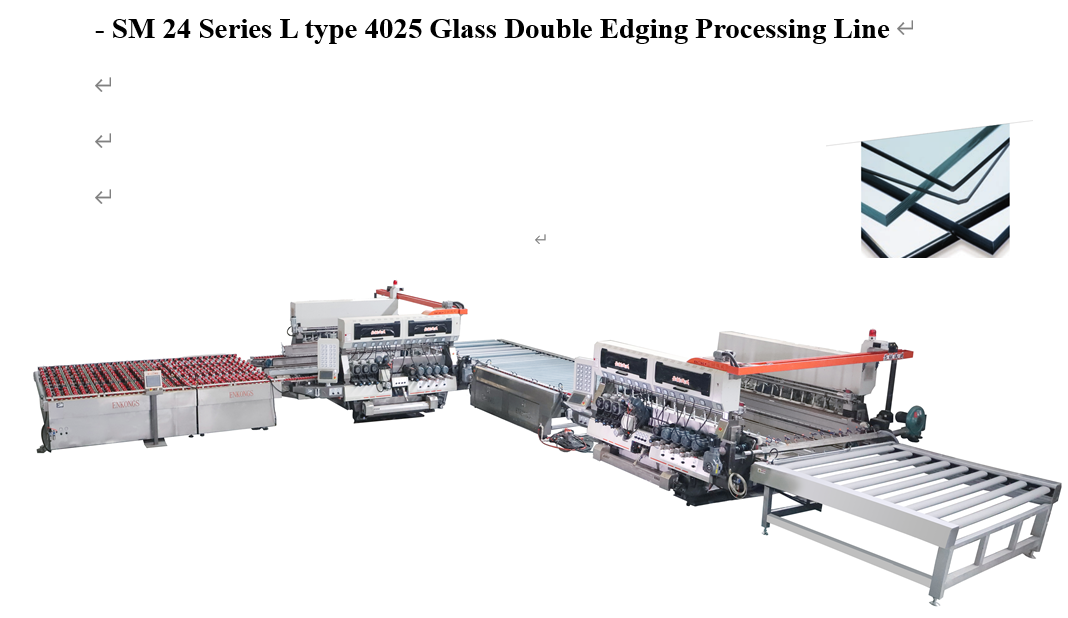

In the realm of glass processing, the efficiency and precision of edge treatment are paramount. Glass double grinding machinery has emerged as a gamechanger, offering a comprehensive solution for glass edge processing. This article will delve into the intricacies of glass double grinding machinery, glass double edging machine, glass double side polisher, glass processing machine, and glass double edger machine, highlighting their importance and applications in the glass manufacturing industry.

Glass double grinding machinery is designed to handle the complex task of edge finishing with ease and precision. This stateoftheart equipment is capable of performing doublesided grinding on glass panels, ensuring a uniform and smooth edge finish. The machinery typically consists of two grinding heads that work simultaneously on opposite sides of the glass, providing a symmetrical and aesthetically pleasing result.

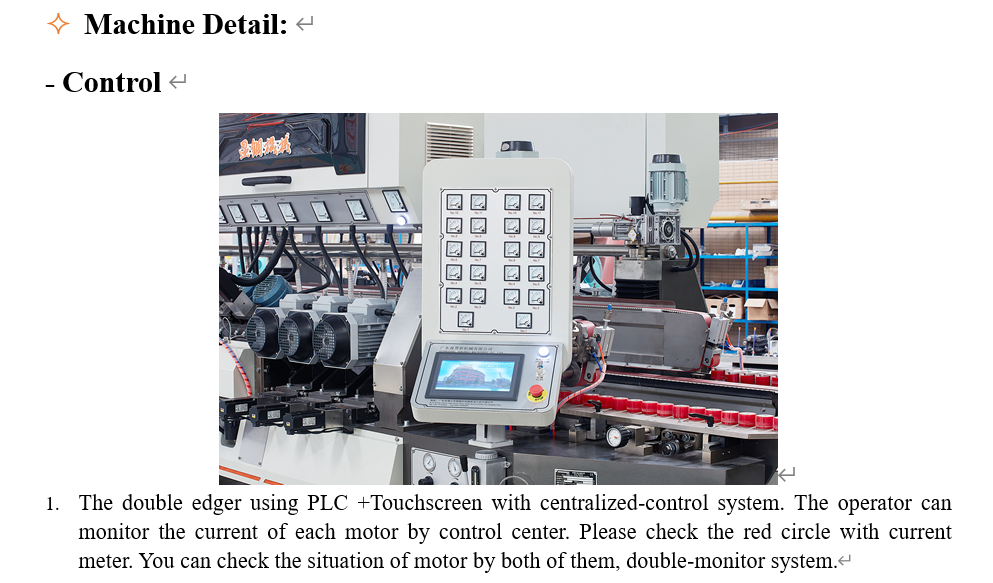

The glass double grinding machinery is equipped with advanced features such as automated feeding systems, precision control mechanisms, and userfriendly interfaces. These features not only enhance the efficiency of the glass processing but also ensure the safety of the operators.

The glass double edging machine is a specialized piece of equipment that excels in creating precise and consistent edges on glass panels. This machine is designed to handle both straight and shaped edges, making it a versatile tool in the glass manufacturing process. The double edging functionality allows for simultaneous processing of both sides of the glass, significantly reducing the time required for edge finishing.

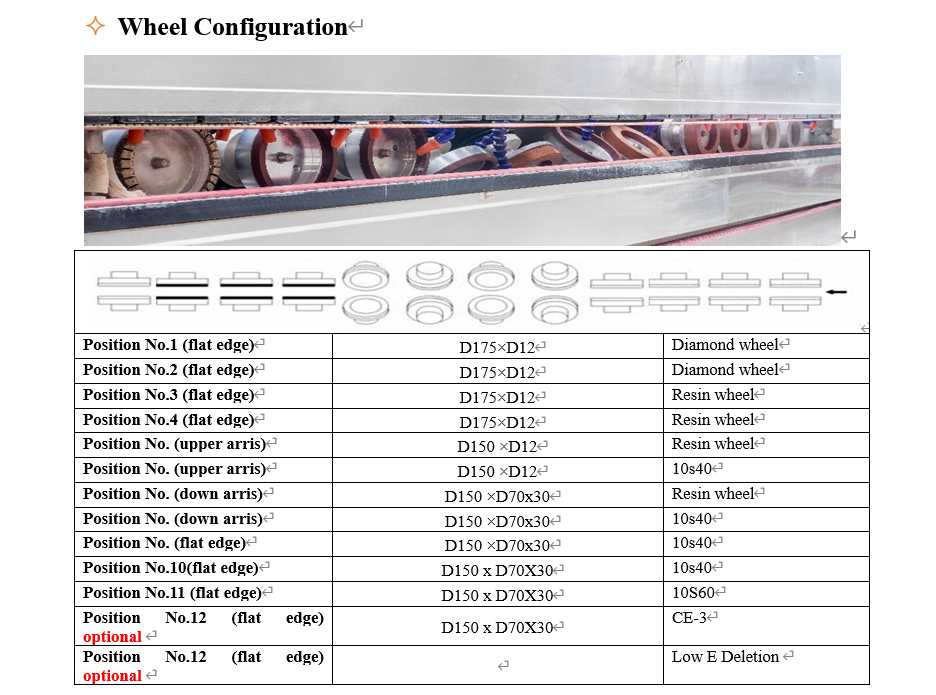

The glass double edging machine is equipped with highspeed spindles and diamondtipped wheels that ensure a smooth and precise cut. The machine's advanced control system allows for easy adjustment of the edging parameters, enabling the production of various edge profiles to meet different design specifications.

After the edges have been ground and edged, the glass double side polisher comes into play to provide the final touch. This machine is designed to polish both sides of the glass simultaneously, removing any remaining imperfections and achieving a highquality, mirrorlike finish. The double side polishing process ensures that the glass edges are not only smooth but also aesthetically pleasing.

The glass double side polisher is equipped with polishing wheels that can be adjusted for different types of glass and desired finishes. The machine's automated features allow for consistent and uniform polishing results, enhancing the overall quality of the glass products.

The glass processing machine is a multifunctional equipment that integrates various glass processing operations into one platform. It can perform tasks such as cutting, edging, grinding, and polishing, offering a complete solution for glass manufacturing. This machine is designed to handle large volumes of glass panels with high precision and efficiency.

The glass processing machine is equipped with advanced software that allows for the customization of processing parameters, ensuring that each glass panel meets the specific requirements of the project. Its automated features reduce manual labor, minimize errors, and increase productivity.

The glass double edger machine is specifically designed for highvolume production environments where precision and speed are crucial. This machine is capable of edging both sides of the glass simultaneously, providing a consistent and highquality edge finish. The double edging functionality significantly reduces the processing time, making it an ideal choice for largescale glass manufacturing operations.

The glass double edger machine is equipped with robust construction and advanced technology that ensures durability and reliability. Its automated features and precision control mechanisms make it a valuable asset in the glass processing industry.

These machines not only enhance the efficiency and precision of glass edge processing but also contribute to the overall quality and aesthetic appeal of glass products. As technology continues to advance, these machines will play an increasingly important role in meeting the demands of the modern glass market.