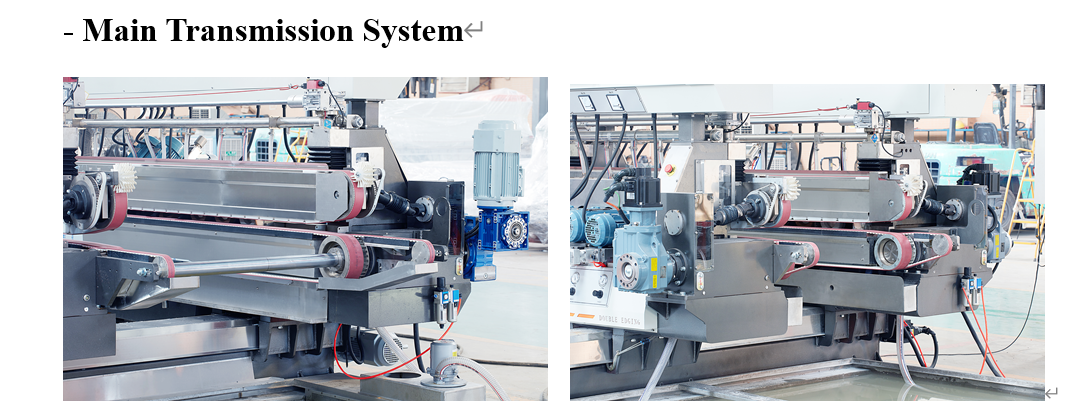

The main gear box shaft sleeve adopts through sleeve structure, using high precision roller bearings, stable and reliable operation, long service life, reduce maintenance cost. Servo motor transmission is also available for option.

1. Standard Model: High performance ABB motors first one adopts 3kw. Inside of the sliding part adopt the bronze nut work with adjustment screw rod to reduce the gap, more flexible and durable.

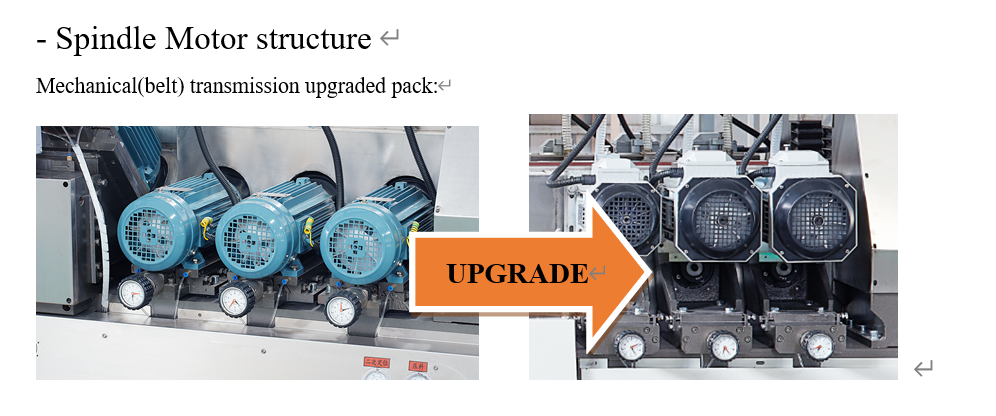

2. Mechanical (belt) transmission: with 4200rpm mechanical transmission by belt driven. Spindles shaft rotation at 4200rpm/min. The shaft can tolerant up to 12000rpm/min maximum, however, only using 1/3 of total speed capacity. The processing speed is upon 15m/min with polishing. Grinding ability has improved

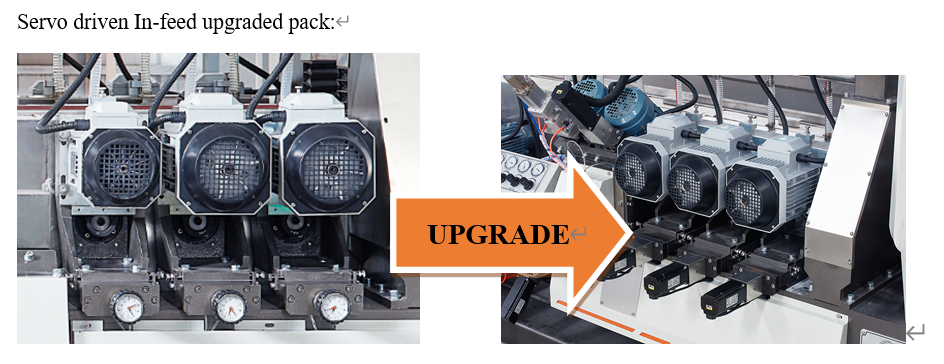

3. Mechanical (belt) transmission with Servo driven In-feed arrangement: Fully automatic wheel adjustment. Precise calculation between wheel and material. Avoiding uneven grinding caused by human error. Stepping into the next automation level.

1. Motor configuration:

- Conveyor motor: variable frequency motor 2.2KW

- Roller conveyor motor 1: variable frequency motor 1.5KW

- Roller conveyor motor 2: variable frequency motor 1.5KW

2. Technical parameters:

1 | Minimum size of the transfer glass: | 350mm * 350mm |

2 | Maximum size of the transfer glass | 2500mm * 1500mm |

3 | Thickness of the transfer glass | 3-25mm |

4 | Total power | 5.2KW |

5 | Dimensions | 8100mm * 2900mm * 1000mm |

Remark: When the size of the transfer glass changes, the external dimensions change accordingly. | ||

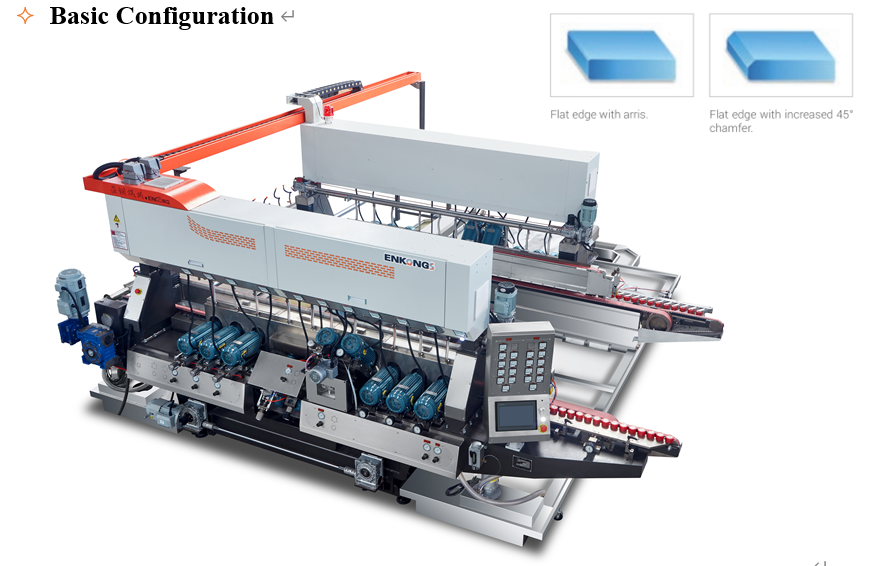

Glass double edging machine, also known as a glass chamfering machine, glass double side polisher, glass grinding machine, or sheet glass edger, is a specialized piece of equipment used in the glass processing industry for grinding and polishing the edges of glass sheets. This machine plays a crucial role in enhancing the quality and aesthetics of glass products, making them more appealing and functional for various applications.

The glass double edging machine is equipped with multiple grinding wheels that rotate at high speeds to remove any sharp edges, burrs, or imperfections from the glass edges. This process not only ensures the safety of handling the glass but also improves the overall appearance and quality of the glass products. The machine can handle glass sheets of various thicknesses and sizes, making it versatile and adaptable to different production requirements.

One of the key features of the glass double edging machine is its ability to perform precise and uniform grinding and polishing on both sides of the glass simultaneously. This ensures that the edges of the glass sheets are smooth, even, and free from any defects, resulting in a high-quality finished product. The machine is also designed to operate efficiently, reducing production time and increasing productivity in glass processing operations.

Safety is also a top priority in the design of glass double edging machines. These machines are equipped with safety features such as emergency stop buttons, protective shields, and safety interlocks to ensure the safety of operators and prevent accidents during operation. This focus on safety not only protects workers but also contributes to the smooth and efficient operation of the machine.