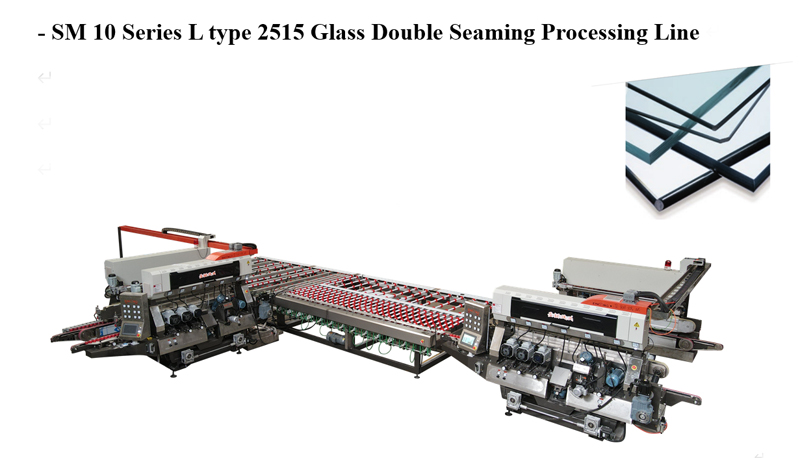

- SM10 Series L Glass Double Seaming Processing Line:

Section | Model | QTY | Info. | |

1 | Glass Straight Line Double Edging Machine | SM 1025 | 1 SET | 2.5 -meter glass edger 5 spindles + 1 |

2 | Transfer table (L type) | SZL2515 | 1 SET | Conveyor from #1 to #2 |

3 | Glass Straight Line Double Edging Machine | SM 1015 | 1 SET | 1.5-meter glass edger 5 spindles + 1 |

Remarks: The last two spindle motor can be optionally equipped with optional low e deletion device or enhanced polishing with extra CE-3. | ||||

General Information:

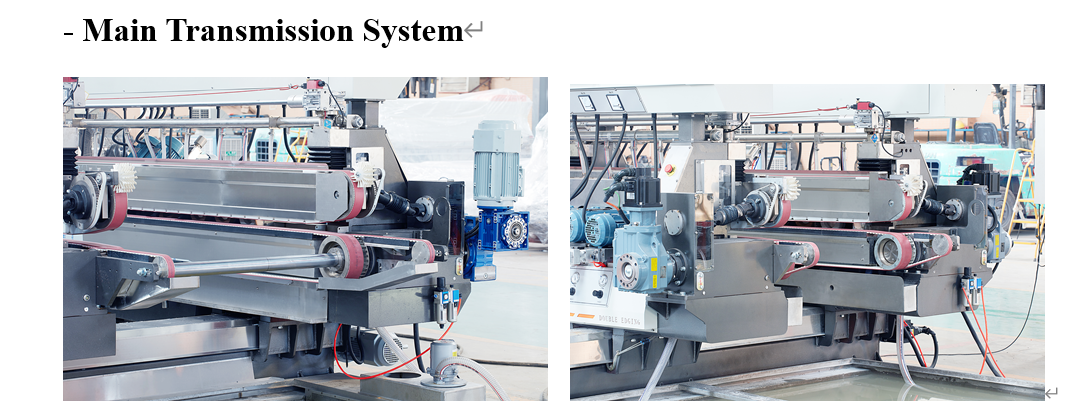

1. The main transmission adopted timing belt (Italian branded) and is equipped with variable frequency motor speed control.

2. Under modular design concept, the double straight edge machine can be equipped with enhanced polishing and low e deletion devices.

3. The polishing spindles can be selected pneumatic polishing or automatic feeding polish which improving the polishing quality and reduce the labor intensity of workers.

4. Safety feature such as safety rope protection mechanism can be find in the machine to protect the operator and maintenance personnel.

5. The whole line has compact structure, which makes the machine has a stable and reliable performance, higher degree of automation, and higher production efficiency.

6. It is the best supporting machine for large-scale furniture and architectural decoration glass processing. It can be paired with production lines such as lamination, printing and tempering.

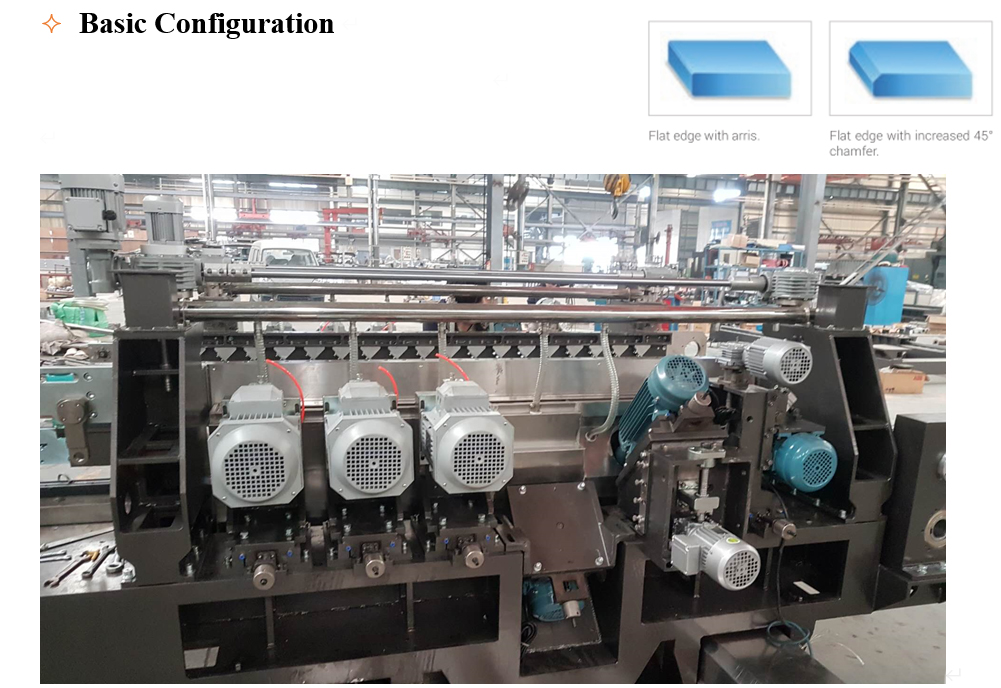

Basic Configuration:

1. Ball screw(Width adjustment): Taiwan HINWIN/TBI/PMI

2. Linear guide: Taiwan HINWIN/TBI/PMI

3. base, movable & fixed bridge, conveyor plate: high-quality steel plate welding after heat treatment finishing

4. Water tank material: Stainless steel SUS201

5.Timing belt: Megadyne,Italy

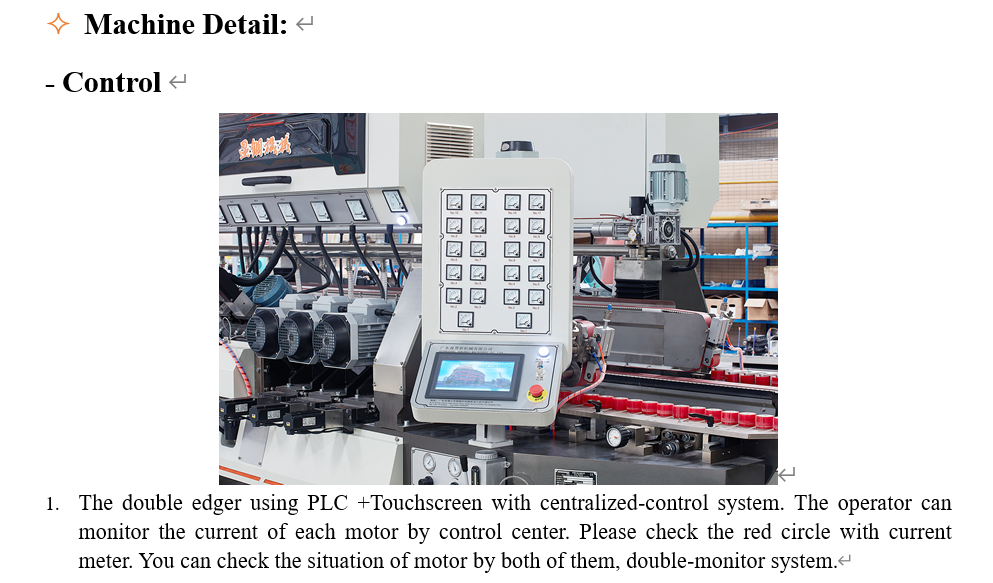

6. Operation: PLC + touch screen control. Fully automatic PLC computer control, touch screen user friendly interface, easy to operate.

Electrical Parts:

Item | Manufacture | Origin |

Low-Voltage apparatus | Schneider | France |

button | Takahashi | CHINA |

Inverter | Delta | Taiwan, China |

transformer | erbian | China |

Encoder | Koyo | Japan |

PLC | Delta / Wing Hong | Taiwan, China |

touch screen | Delta | Taiwan, China |

Servo system | Delta / Wing Hong/ | Taiwan, China |

The main gear box shaft sleeve adopts through sleeve structure, using high precision roller bearings, stable and reliable operation, long service life, reduce maintenance cost. Servo motor transmission is also available for option.

1. Standard Model: High performance ABB motors first one adopts 3kw. Inside of the sliding part adopt the bronze nut work with adjustment screw rod to reduce the gap, more flexible and durable.

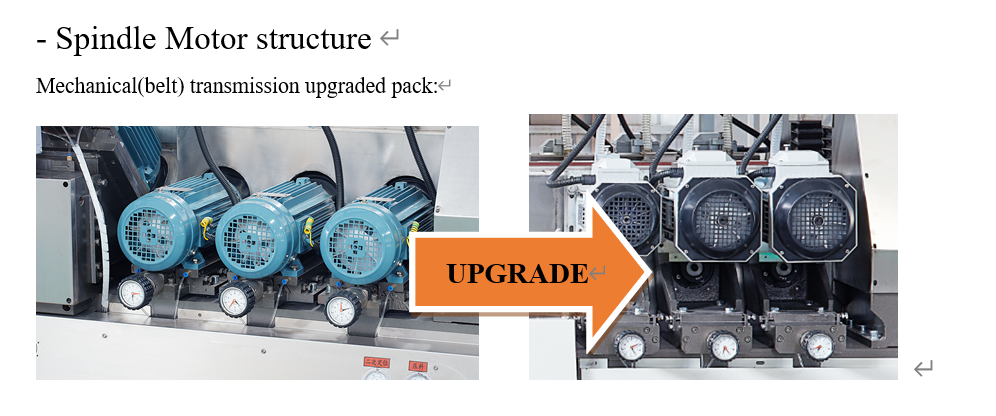

2. Mechanical (belt) transmission: with 4200rpm mechanical transmission by belt driven. Spindles shaft rotation at 4200rpm/min. The shaft can tolerant up to 12000rpm/min maximum, however, only using 1/3 of total speed capacity. The processing speed is upon 15m/min with polishing. Grinding ability has improved

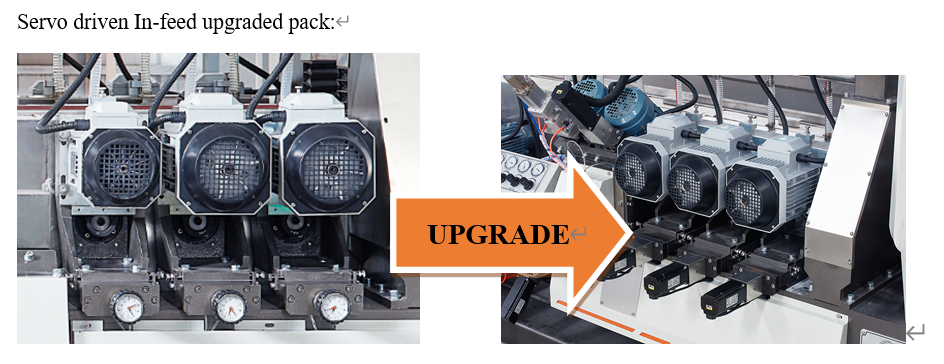

3. Mechanical (belt) transmission with Servo driven In-feed arrangement: Fully automatic wheel adjustment. Precise calculation between wheel and material. Avoiding uneven grinding caused by human error. Stepping into the next automation level.

In the modern glass manufacturing industry, precision and quality are paramount. Among the various types of machinery that facilitate the production of high-quality glass products, the glass edging machine stands out as a crucial component. This article will explore the significance of glass edging machines, including related equipment such as glass double sides edgers, glass double seaming machines, and glass polishers, while highlighting the broader category of glass machinery.

A glass edging machine is specifically designed to grind and polish the edges of glass sheets, ensuring that they are smooth and safe for handling. The edging process is vital for both aesthetic and safety reasons. Sharp edges can pose a risk of injury, while well-finished edges enhance the overall appearance of the glass product.

Glass edging machines come in various configurations, including straight-line edging machines and double-sided edgers. The latter is particularly noteworthy, as it allows for simultaneous processing of both sides of a glass sheet, achieving a uniform finish more efficiently than traditional methods.

The glass double sides edger is a specialized type of glass edging machine that provides a dual-sided finish. This machine is particularly advantageous for manufacturers looking to produce high-quality glass products that require polished edges on both sides. The double-sided edger operates with precision, leveraging advanced technology to ensure that the edges are not only smooth but also consistent in thickness and profile.

One of the primary benefits of using a glass double sides edger is its efficiency. By processing both sides of the glass simultaneously, manufacturers can significantly reduce the time needed for edge finishing. This efficiency translates into higher productivity and lower labor costs, making it an attractive investment for glass manufacturing businesses.

While glass edging machines focus on the finishing of edges, glass double seaming machines play a complementary role in the production process. These machines are used to create seams between glass panels, particularly in applications such as glass doors, windows, and facades. The double seaming process ensures that the seams are strong and durable, contributing to the overall integrity of the glass structure.

The integration of glass double seaming machines within a glass manufacturing facility enhances the production workflow. By ensuring that edges and seams are processed with precision, manufacturers can produce glass products that meet stringent quality standards.

Another essential piece of equipment in the glass finishing process is the glass polisher. After the edging process, glass panels often require additional polishing to achieve a high-gloss finish. Glass polishers are designed to remove any remaining imperfections and enhance the clarity of the glass. This final step is crucial for applications where optical clarity is of utmost importance, such as in display cases or architectural glass.

Glass polishers come in various configurations, including manual and automated systems. Automated polishers, in particular, enhance efficiency and consistency, allowing manufacturers to produce large volumes of polished glass with minimal labor input.

The glass industry relies heavily on specialized machinery to produce high-quality products. Glass edging machines, double-sided edgers, double seaming machines, and polishers are all integral components of the glass manufacturing process. Together, they form a comprehensive system that allows for the efficient production of glass products that meet both aesthetic and safety standards.

Investing in advanced glass machinery not only improves product quality but also enhances operational efficiency. Modern glass manufacturing facilities are increasingly adopting automated systems to streamline production, reduce waste, and improve overall productivity. This trend reflects the industry's commitment to innovation and quality.

Glass edging machines, including glass double sides edgers, glass double seaming machines, and glass polishers, play a pivotal role in the glass manufacturing industry. These machines ensure that glass products are not only visually appealing but also safe for use. As the industry continues to evolve, the importance of investing in advanced glass machinery will only grow. Manufacturers who embrace these technologies will be well-positioned to meet the demands of a competitive market while delivering high-quality glass products to their customers.

In an age where precision and quality are non-negotiable, the glass edging machine and its associated equipment stand as a testament to the advancements in glass manufacturing technology, ensuring that the industry can meet the challenges of today and tomorrow.