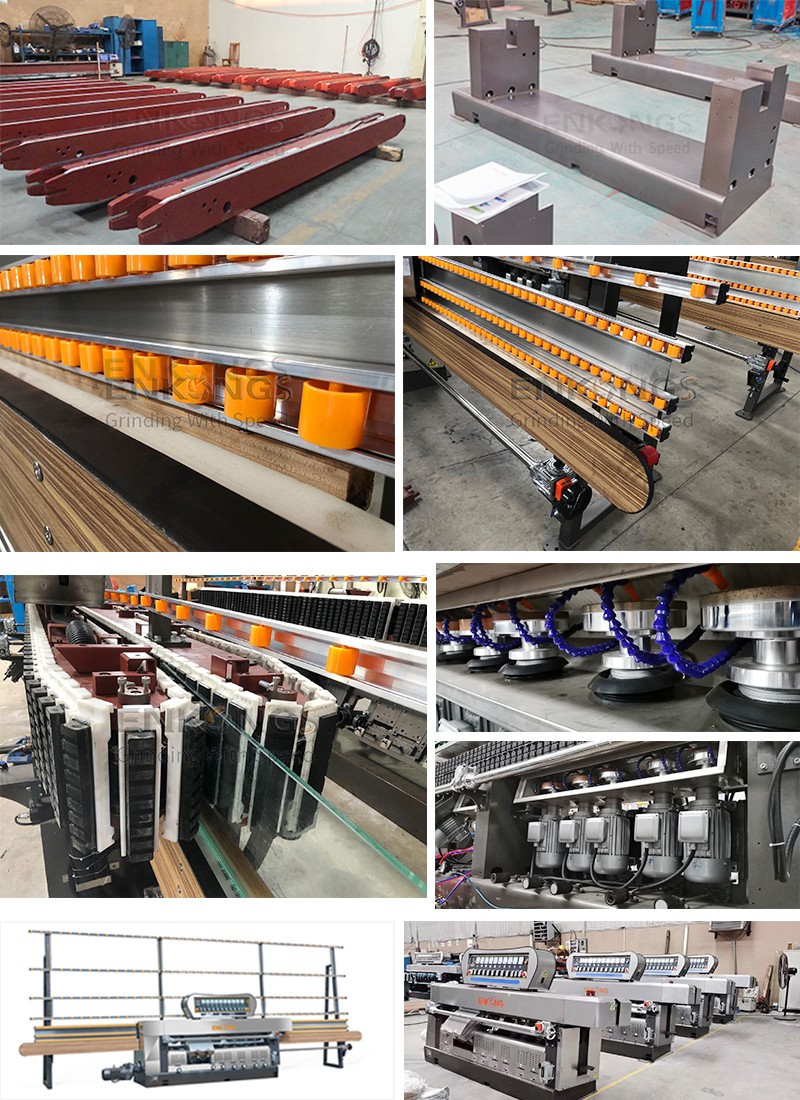

In the glass processing industry, ENKONGS 4 spindles glass straight-line edging machine plays an integral role in shaping and finishing the edges of glass sheets. This equipment is designed to perform precise grinding, edging, and polishing tasks on glass edges, ensuring smooth and aesthetically appealing results. Equipped with four spindles, the machine can process multiple edges at once, making it highly efficient and suitable for both small and large-scale production. As part of the broader category of glass edging machines, the 4-spindle glass straight-line edging machine is tailored to meet various needs, ranging from architectural glass production to custom glass fabrication. The 4 spindles glass straight-line edging machine is a specialized tool designed to grind, shape, and polish the edges of glass sheets with precision. As a part of the broader category of glass edging machines, this equipment combines both high precision and efficiency in edge treatment, which is critical in industries where glass quality is paramount.

ENKONGS glass edging machine is an essential tool for producing clean, polished edges on glass sheets. Whether used for decorative purposes or to ensure the safety and functionality of glass products, these machines are crucial in the glass manufacturing process. The 4 spindles glass straight-line edging machine offers versatility, allowing operators to perform both rough grinding and fine polishing on glass edges.

ZM4 glass rough grinding machine is equipped with multiple spindles (four in this case), which allow for simultaneous edge processing, increasing efficiency. Typically, glass edging machines are used in the construction, automotive, and furniture industries, where high-quality glass products are required. By offering different edge profiles and finishes, the glass edging machine can handle glass sheets of various sizes and thicknesses.

Technical Specifications of ZM4Y 4 spindles glass edger:

1. Processing glass thickness: 3~25mm

2. Angle of arris:45°

3. Min. size of processing glass:80mm×80mm

4. Max.Size of processing glass

5. Processing speed:1.26~6.3 m/min

6. Installed power: 9.15KW

7. Occupation: 5.8m×1.1m

8. The Package size: 3.3m×0.9m×1.5m

9. Weight: 1700KGS

10. Stainless steel water tank

11. The infeed and outfeed adopts Timing belt to convey.

12. Chinese Brand Motor (Made-in-China)

2.Glass Rough Grinding Machine

The glass rough grinding machine function in the 4-spindle glass straight-line edging machine is a key component in the initial stages of glass edge processing. The rough grinding stage removes excess material from the edges of the glass sheet, shaping it to the required profile. ZN4Y glass straight-line processing machine is essential to use high-quality grinding wheels made from durable materials such as diamond or resin to ensure that the grinding process is effective and precise.

During this stage, the rough grinding heads of the 4-spindle glass straight-line edging machine ensure that the glass edges are shaped uniformly and prepared for the subsequent polishing stage. The grinding wheels are adjustable, which allows the operator to set the appropriate grinding pressure, speed, and depth for different glass thicknesses and sizes. The glass rough grinding machine function is vital for preparing the glass for finer edge treatment.

3. CNC Center

4. workshop corner for edgers

Certificate