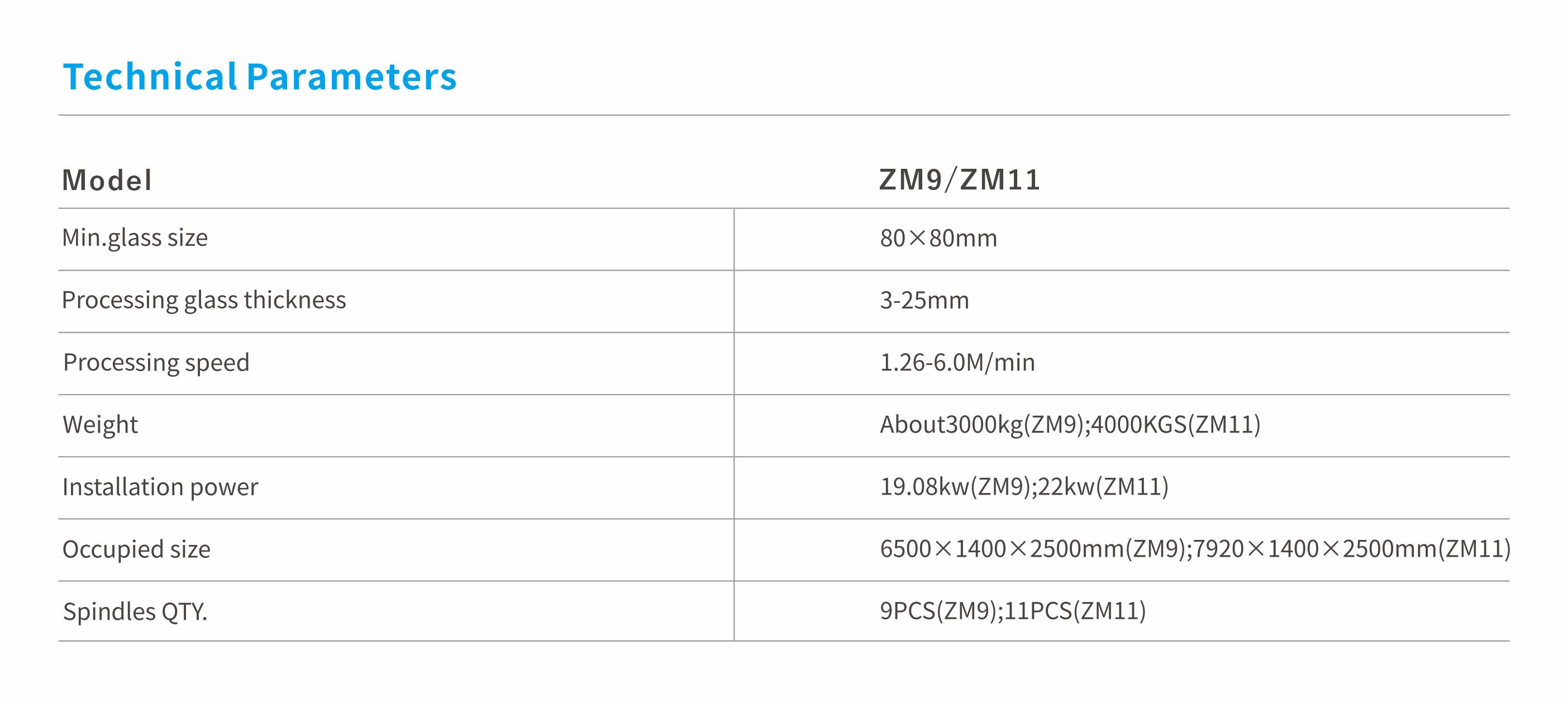

ENKONGS’ ZM9 glass straight line polishing machine, also known as an automatic glass polisher, is a specialized piece of equipment used in the glass processing industry. This machine is designed to grind and polish the edges of glass panels to achieve a smooth and uniform finish.

ZM9 glass edging machine is an automatic glass machine specially designed for glass edging treatment. The machine combines automation,

high-speed operation and multi-head grinding to efficiently process glass materials of different thicknesses, especially for flat polished edge glass production.

The rough grinding, precise grinding, and angel making can be finished at one time. With advanced design concepts and robust construction, it can meet the needs of large-scale industrial production.

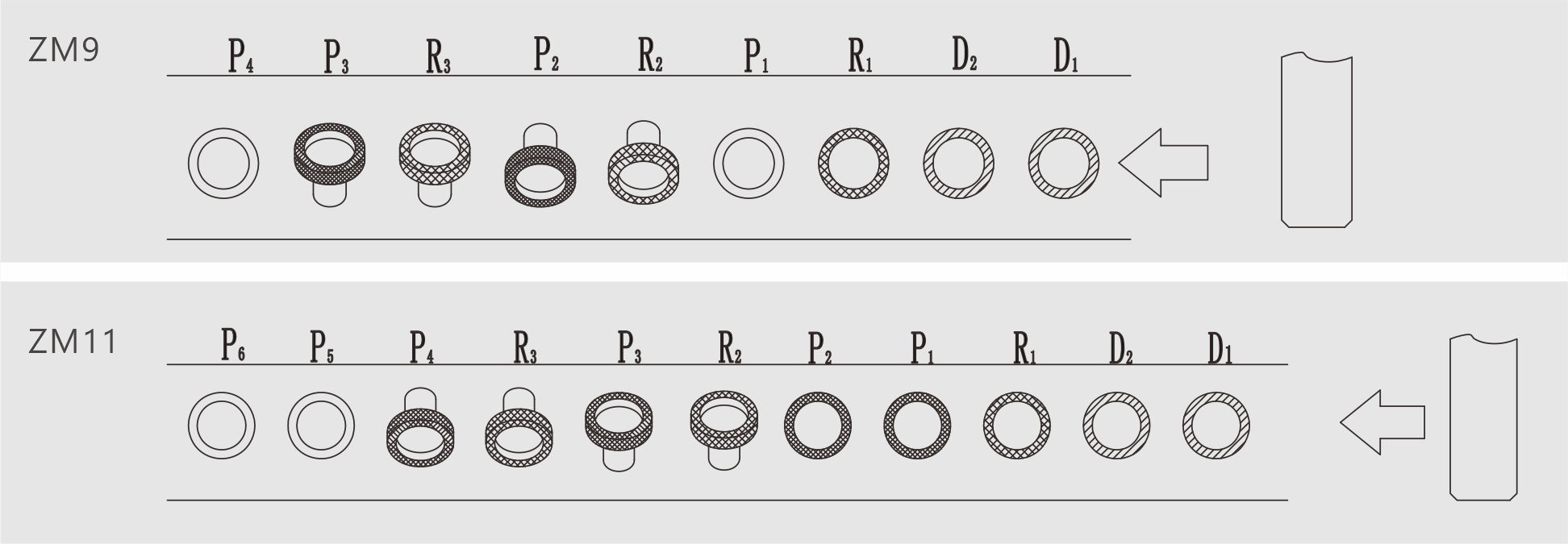

The glass straight line polishing machine features a conveyor belt system that moves the glass panels through a series of polishing wheels. These wheels are equipped with abrasive materials that effectively remove any rough edges or imperfections on the glass surface.

One of the key benefits of using a glass straight line polishing machine is its efficiency and precision. ENKONGS glass processing machine is capable of polishing multiple glass panels simultaneously, ensuring a consistent and high-quality finish. This not only saves time but also improves the overall productivity of the glass processing operation.

Automatic glass machines signify a substantial leap forward in the glass processing industry. These machines automate the comprehensive process of converting raw glass sheets into products with precise shapes, dimensions, and finishes. By integrating multiple functions such as cutting, grinding, polishing, and edge finishing into an integrated system, automatic glass machines have significantly enhanced production efficiency, precision, and consistency.

The primary advantage of ENKONGS glass processing machine is their high degree of automation. Traditional manual methods of glass processing were not only labor-intensive but also susceptible to human error, leading to inconsistencies in product quality. With the introduction of automatic glass machines, we can now achieve superior quality standards while simultaneously reducing labor costs and production time.

Among the various types of glass processing equipment, automatic glass grinding machines are crucial for shaping and finishing glass edges. These machines are specifically designed to perform rough grinding, fine grinding, and polishing of glass edges in one time, ensuring that each sheet of glass is perfectly processed to meet industry standards.

Enkongs glass equipment advantages.

1. High Precision: ENKONGS automatic glass grinding machines guarantee uniform edge finishing with exceptional accuracy, thereby minimizing the likelihood of defects.

2. Time Efficiency: The integration of rough grinding, fine grinding, and polishing into a single machine substantially reduces processing time.

3. Cost-Effectiveness: By consolidating multiple processes into one machine, we can significantly lower both capital expenditures and operational costs.

4. Enhanced Edge Quality: ENKONGS autamatic glass grinding machines deliver impeccably polished edges, which is crucial for premium applications such as shower room glass and glass staircases.

Technological Features of Automatic Glass Grinding Machines

Modern automatic glass grinding machines are outfitted with state-of-the-art technology that significantly enhances their operational efficiency and precision. A pivotal technological advancement is the incorporation of high-performance grinding wheel motors. These motors provide superior power and accuracy, enabling faster processing speeds and finer surface finishes.

Additionally, automatic glass grinding machines offer versatile processing modes to accommodate diverse production needs. For instance, some models feature a "batch processing mode," allowing for the simultaneous processing of multiple glass sheets in a single cycle, while others are configured for "single piece processing," making them suitable for smaller or custom-sized orders.

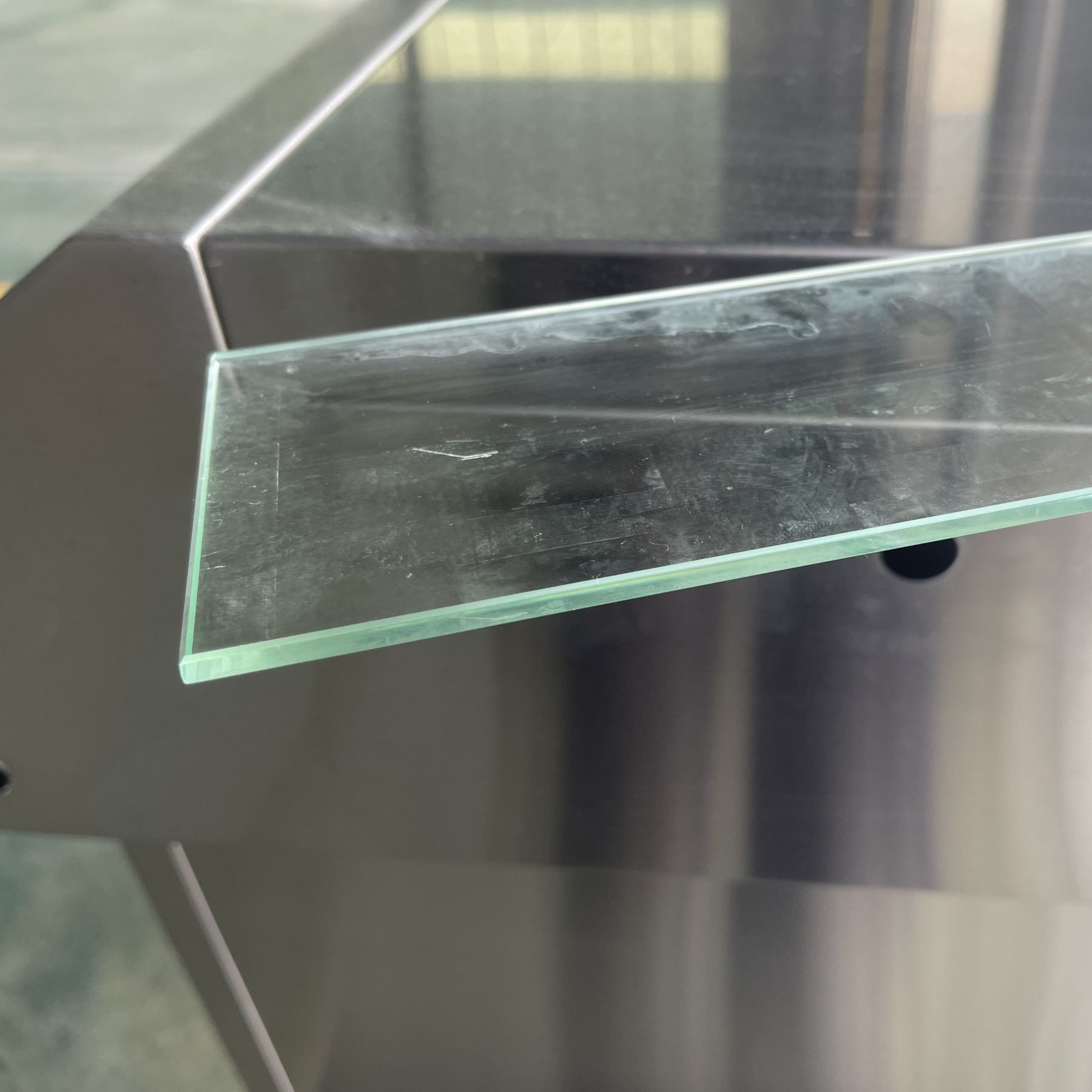

Flat polished edge glass is a type of glass product that features a smooth, polished edge that is both aesthetically pleasing and functional. This type of glass is commonly used in applications where the edge quality is critical, such as in glass furniture, shower enclosures, and glass staircases.

Flat polished edge glass offers both aesthetic and functional benefits. The polished edges not only make the glass look more attractive but also reduce the risk of sharp corners, making it safer to handle and install. This type of glass is often favored in high-end architectural projects for its sleek, modern look. And ENKONGS glass equipment can do it.

To achieve flat polished edges, a series of steps are involved, including rough grinding, fine grinding, and polishing, usually carried out by automatic glass grinding machines. These processes work together to ensure the edges are smooth, even, and free of any defects.

The integration of automatic glass machines, automatic glass grinding machines, flat polished edge glass, and advanced glass processing equipment has revolutionized the glass manufacturing industry. These technologies have enabled manufacturers to achieve higher precision, efficiency, and flexibility in their production processes, resulting in the creation of high-quality glass products that meet the needs of modern architecture and design.

From constructing impressive glass facades to designing sleek shower enclosures and elegant glass staircases, the impact of automatic glass processing machines is undeniable. As technology continues to evolve, these machines will play an even greater role in shaping the future of the glass industry, opening up new possibilities for innovation and customization.

All in all, Choose ENKONGS glass edgers to make your deep glass processing more portable, faster and cost effective.