This line can making double insulating glass and three insulating glass automatically.

1. It adopts imported PLC control system, which reach digitizing & Control unit. It has many advantages: steady work, high automation, easy operation and high efficiency. This model can achieve 800 pieces finished glass at one shift 8 hours.

2. It uses human machine interface touching screen. Worker can transfer the auto and manual easily. On the touching screen, worker can get the line processing condition and error condition. Besides, It has single section operation function.

3. We uses anti-acid & alkali rubber delivery wheel.

4. Cleaning section adopts high quality stainless steel material. It has 6 piece brush water cleaning device and 2 stages cleaning, which can ensure the glass clear enough. Special design spraying device, which angle can be adjusted according to demand. It is easy to be cleaned and maintained. Besides, it has water heating device. If the temperature is lower than 7°, we suggest that you can consider using it.

5. This line has automatic LOW-E identification system and install special brush for LOW-E glass.

6. There is water mist separator in drying section, which can ensure glass drying fully.

7. Each transporting section adopts buffer stop function, which can avoid the bumping phenomenon and reduce the wear and tear of delivery wheel.

8. Delivery back board adopts double surface polyurethane high strength MDF, which is suitable for the insulating glass work in long time.

9. Germany technology blowing knife, which distance can be adjusted according to glass thickness.

10.Aerial plug is interference free performance function and it is easy to be installed and maintained.

11. Adopts hydraulic drive. The action is led by four points same step rack and pinion. This design can ensure the level assembly of double pressing board. According to different size glass, it has pressure adjusting function. The pressure keeping time also can be adjusted according to glass size.

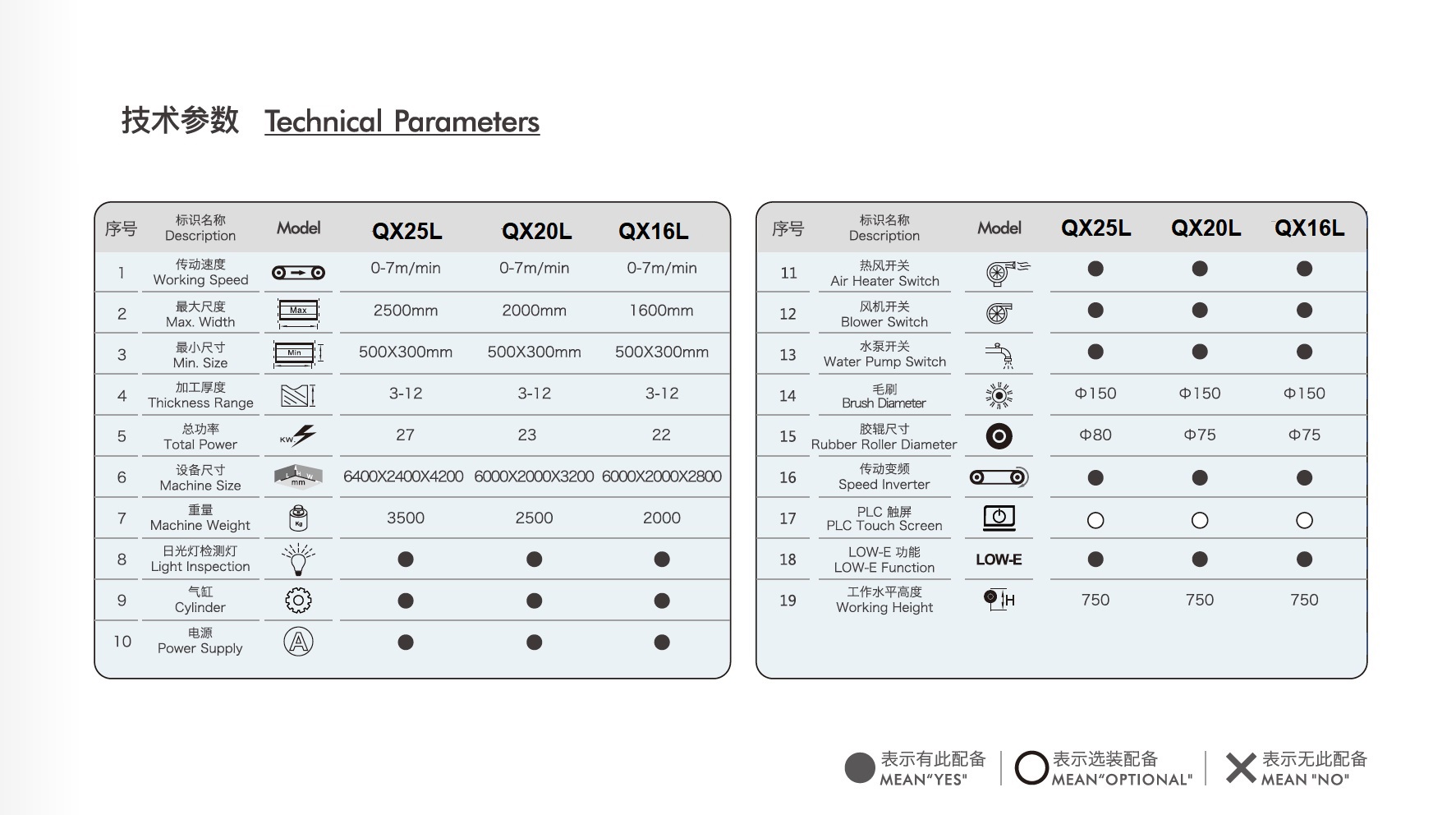

Technical Parameter

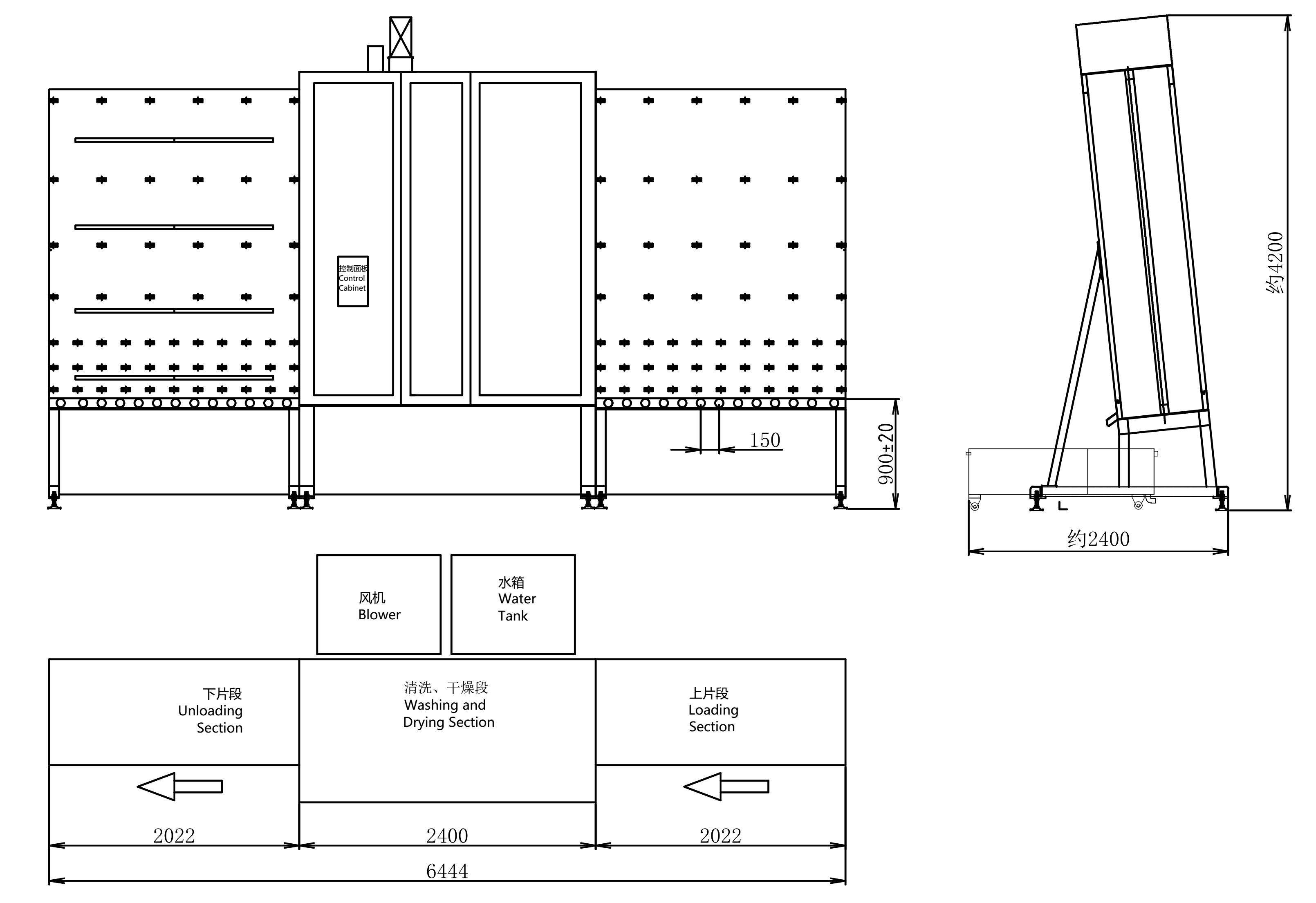

Lay-out

Machining center

Certificate

Service

Glass vertical washing machines are designed to clean glass sheets in a vertical orientation. These machines are particularly useful in the production of larger glass panels, such as those used in architectural applications, windows, and doors. The vertical design allows for efficient cleaning of both sides of the glass simultaneously, ensuring a streakfree finish. The machine typically uses a combination of water, detergent, and highpressure jets to remove dust, dirt, and other contaminants from the glass surface. The automated nature of these machines not only ensures consistent cleaning quality but also increases productivity by reducing manual labor.

The glass washing machine is a broader term that encompasses various types of glass cleaning equipment, including both vertical and horizontal models. These machines are designed to clean glass sheets of different sizes and shapes, making them versatile for various industrial applications. Glass washing machines are equipped with brushes, sprayers, and squeegees to scrub, rinse, and dry the glass, ensuring a spotless finish. They are commonly used in glass manufacturing plants, furniture factories, and even in the automotive industry for cleaning glass components.

When it comes to commercial applications, the best commercial glass washer is a topoftheline machine designed to meet the high demands of commercial environments. These washers are built to handle large volumes of glass sheets with ease and efficiency. They often feature advanced technology such as programmable settings, automated cleaning cycles, and quickdry systems. The best commercial glass washers are known for their durability, reliability, and the superior quality of the cleaning results they deliver. They are an essential component in the production lines of glass processors who supply to the construction, architectural, and retail sectors.

The glass washer machine is a term that can refer to both manual and automatic glass cleaning equipment. These machines are designed to clean glass sheets thoroughly, removing any impurities that could affect the final product's appearance or functionality. The glass washer machine typically consists of a series of stages, including prewashing, main washing, rinsing, and drying. Each stage is carefully designed to ensure that the glass is cleaned to the highest standards. These machines are indispensable in industries where glass products are subject to stringent quality control measures.

In the context of glass manufacturing, the efficiency and effectiveness of the cleaning process are crucial. Here's a more detailed look at the features and benefits of these glass cleaning machines:

1. Glass vertical washing machine: This machine's vertical design optimizes space and allows for the cleaning of large glass panels. It ensures that both sides of the glass are cleaned evenly, reducing the risk of streaks and spots.

2. Glass washing machine: With its versatility, this machine can handle a wide range of glass sizes and shapes. It is an essential tool for glass processors who need to clean various types of glass products.

3. Best commercial glass washer: Designed for highvolume applications, this machine offers superior cleaning performance and reliability. It is ideal for businesses that require consistent and efficient cleaning of glass sheets.

4. Glass washer machine: Whether manual or automatic, this machine provides a thorough cleaning process that is essential for maintaining the quality of glass products. It helps in achieving a smooth and clear finish on the glass surface.

The benefits of using these glass cleaning machines are manifold:

Improved Product Quality: Clean glass sheets are free from defects and impurities, which enhances the overall quality of the final product.

Increased Efficiency: These machines automate the cleaning process, reducing the time and labor required to clean glass sheets manually.

Cost Savings: By ensuring that glass products meet quality standards, these machines help in reducing waste and rework, leading to cost savings.

Consistency: The automated cleaning process ensures consistent results, which is crucial for meeting the demands of highquality glass products.

Glass cleaning machines are an integral part of the glass processing industry. The Glass vertical washing machine, glass washing machine, best commercial glass washer, and glass washer machine each offer unique features and benefits that cater to the diverse needs of modern industries. By investing in the right glass cleaning equipment, businesses can enhance their production efficiency, reduce costs, and deliver highquality glass products to their customers.