ENKONGS glass straight-line edging machine is a pivotal piece of equipment in the glass processing industry, designed to smooth and shape the edges of glass sheets with high precision and consistency. Whether for architectural applications, mirrors, furniture, or custom glass work, the glass straight-line edging machine provides the necessary features and capabilities to deliver top-quality results.

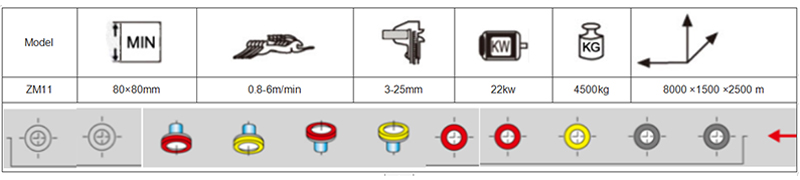

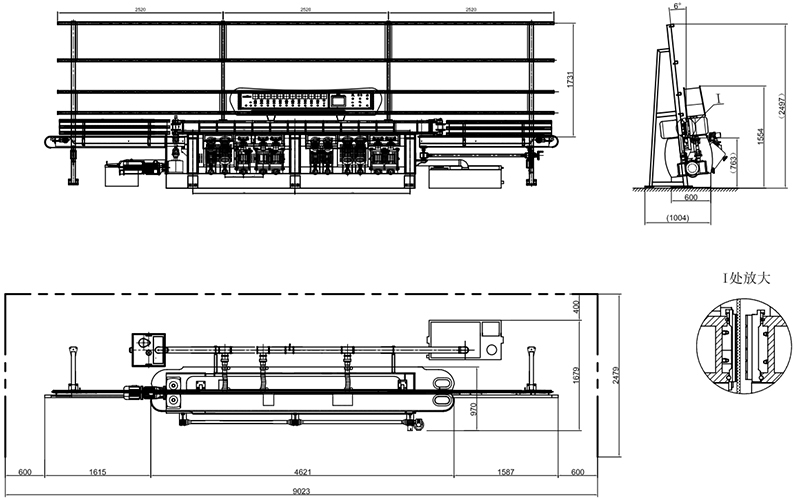

ENKONGS ZM11 glass straight line edging machine is suitable for different size and thickness flat glass grinding, glass processing edging machine can rough grinding、fine grinding and polishing finish in one time; the polishing flat is similar to the smooth degree of glass body, While adjusting the different processing thickness,(you can reference the digital display in front beam to adjust);front chamfer motor can move synchronically with front beam; with advanced structure; high precision,easy operation. Glass processing edging machine is the necessary tool for glass machinery.The 11motors machine is mainly used for grinding bottom edges and large edges of flat glass, its grinding motor are very reasonably distributed, 7 pcs of which are used for grinding bottom edges, 4pcs for grinding 45-degree sharp edges, glass edging machine can be used for precisely grinding flat bottom edges .The machine has highly practical, simply operation, glass edging machine is suitable for professional furniture, doors, windows, kitchen, craft, construction glass grinding.

ZM11 glass edge polishing machine is suitable for processing straight-line edge & 45°arrises of glass sheet with various sizes and thicknesses.

The glass edger’s overall housing, fittings, bases made of cast iron.

The glass thickness can be showed on a digital display or touch screen.

With a special design of the in-feed section for controlling the desired amount of glass removal, the operator does not need to adjust each spindle individually.

The independent felt wheel and the cerium water system can make the flat edge more shining.

The input and output conveyor of the glass edger adopt timing belt which can improve the transmission precision.

glass edging machine is easy to operate and the glass edger has good performance.

The glass straight-line edging machine is designed specifically to process the edges of glass sheets, creating smooth, polished finishes with a straight edge. These machines are equipped with multiple grinding wheels that allow for the grinding, shaping, and polishing of the edges in a sequential, straight-line motion. The primary purpose of this machine is to eliminate sharp edges, improve the visual quality of the glass, and prepare it for further processing or installation.

A glass straight-line edging machine typically features several key components:

Grinding Wheels: These wheels are made of various materials, including diamond, resin, or ceramic. They are used to remove excess material from the edges of the glass, shaping them to the desired profile.

Polishing Units: After the grinding process, the glass edge polishing machine is employed to give the glass edges a smooth, glossy finish. Polishing is essential for removing any surface imperfections and ensuring that the edges are free of rough spots or scratches.

Conveyor Belt: Most modern glass straight-line edging machines are equipped with conveyor belts that transport the glass through the various stages of the edging process. The conveyor system improves efficiency and consistency by automating the handling of glass sheets.

Control Systems: Many advanced glass straight-line edging machines feature automatic control systems that allow operators to adjust the speed, pressure, and angle of the grinding and polishing processes. These adjustments ensure that the glass is processed to exact specifications, providing precise results for each glass sheet.

ENKONGS glass processing edging machines are equipped with automated feeding systems that transport the glass through the grinding, shaping, and polishing stages. The integration of automated controls improves the efficiency and consistency of the process by reducing the risk of human error. Additionally, operators can adjust settings such as grinding speed, polishing pressure, and edge profile to suit different types of glass, enhancing the machine's versatility and performance.

Wheels arrangement and lay-out.

Lay-out

Machining center

Certificate

Service