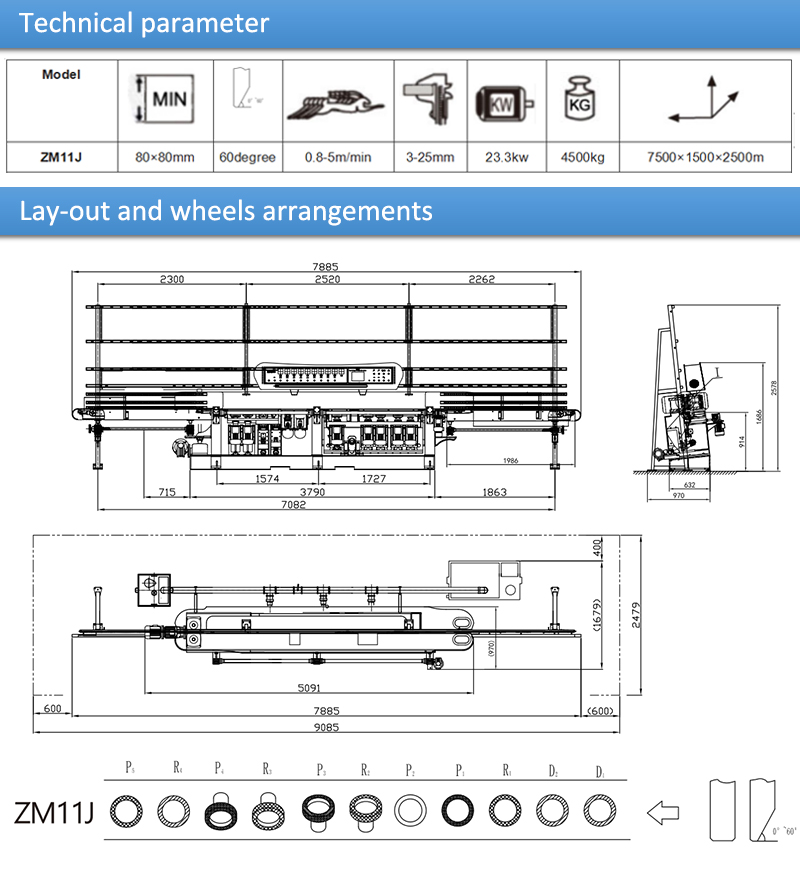

ZM11J glass flat edger&variable miter machine

Glass Straight Line Multi Edging Machine is suitable for mitering glass from a 0 - 60 degree angle.

The machine is designed to coarse/fine grinding and polishing flat glass. Big pitch chain gear is adopted for conveying which makes a stable conveying and high precision process.9 grinding head motors each gets its own oil lubricating circuit which makes no rusting and smooth working and long service live. Push the button, the 5 motors as one unit swaying frame to swing from 0-60degree. The input/output ends can be adjusted from 90 degree to 45 degree and this is realized by lifting guide rail but without need of adjusting grinding wheels.Can be optional PLC and Touch SCREEN controlled. it is suitable for professional furniture, doors, windows, kitchen, craft, construction glass grinding.

This machine has 5motors(No.1-No.5) which can process glass bottom edge and front arris(0-60 degree), NO.6&7 motors for front arris and No.8&9 motors for rear arris All process is finished at one processing.

To make flat edging/polishing, No.1-No.5 motors need to stay at ZERO degree .

To make miter edge, No.1-No.5 motors can be adjused to the requested degree.

Option: This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx40mm) and heavy glass(4mx4m) processing.

The machine adopt PLC control and operator interface(Touch screen). The machine has 2 working modes, manual and fully automatic working mode. In automatic mode, the parameters of glass can be input through Touch screen. In manual mode, machine can be operated through the switch on the working panel.

The glass industry relies heavily on specialized machinery to transform raw materials into finished products. Glass industry machinery includes a variety of equipment designed for specific tasks such as cutting, shaping, polishing, and edging. Among these, the glass edging machine is particularly important as it is responsible for creating the smooth, finished edges that are essential for the safety and aesthetic appeal of glass products.

Glass grinding equipment is a category of machines that are used to grind and finish the edges of glass sheets. These machines are designed to handle the rigors of glass processing, which requires precision and durability. The glass edging machine is a prime example of glass grinding equipment, utilizing abrasive wheels or diamondtipped tools to shape and smooth the edges of glass to the desired specifications.

Glass processing tools encompass a broad range of instruments and devices that are used in the manufacturing and finishing of glass products. These tools can include cutting blades, polishing pads, and edging wheels. The glass edging machine itself is equipped with a variety of glass processing tools that allow it to perform different types of edging operations, such as flat edging, beveling, and pencil edging.

A glass working machine is any device used to shape, cut, or finish glass. This category includes machines like glass cutters, glass polishers, and, of course, glass edging machines. The glass edging machine is a key component in the glass working process, as it is responsible for creating the edges that will be exposed in the final product, ensuring they are safe to handle and visually appealing.

The grinding glass machine is a specific type of glass working machine that is used to grind the edges of glass sheets. This process is critical for removing sharp edges and creating a smooth finish. The glass edging machine falls under this category, as it uses grinding wheels to shape and finish the edges of glass. The precision and speed of the glass edging machine make it an indispensable tool in the glass manufacturing process.

The glass edging machine is designed to handle glass sheets of various sizes and thicknesses. It typically consists of a series of abrasive wheels or diamondtipped tools that are mounted on a rotating spindle. The glass sheet is fed into the machine, and as it passes through, the wheels or tools grind down the edges to the desired shape and finish.

There are several types of glass edging machines, each designed for specific applications:

1. Single Edging Machine: This machine is used for creating a simple, flat edge on glass sheets. It is ideal for products like glass tables and shelves where a basic edge finish is required.

2. Double Edging Machine: This machine is capable of edging both sides of the glass simultaneously, providing a consistent and symmetrical finish. It is often used for glass doors and windows.

3. Beveling Machine: This type of glass edging machine is used to create a beveled edge on glass, which can add an elegant touch to the product. Beveling is common in decorative glass applications.

4. Pencil Edging Machine: This machine creates a rounded edge on glass, similar to a pencil. This type of edge is often used in glass products that require a soft, comfortable feel, such as glass handles.

5. Automatic Edging Machine: This is a highly advanced glass edging machine that automates the edging process, increasing efficiency and precision. It is ideal for highvolume production environments.

The glass edging machine is not only essential for the aesthetic finish of glass products but also for their safety. Sharp edges can be dangerous, and the glass edging machine ensures that all glass products have smooth, safe edges that are ready for use or further processing.

The glass edging machine is a critical piece of glass industry machinery. As glass grinding equipment, it performs essential glass processing tasks with precision and efficiency. As a glass working machine, it shapes and finishes glass to meet the demands of modern applications. The glass edging machine is a cornerstone of the glass manufacturing process, enabling the creation of highquality, safe, and aesthetically pleasing glass products. Whether it's a simple flat edge or a complex beveled design, the glass edging machine plays an indispensable role in bringing glass products to life.