加工玻璃厚度 Thickness | 3-19mm |

最小玻璃尺寸 Min. glass size | 120*120mm |

加工速度 Processing speed | 0.8-4.1m/min |

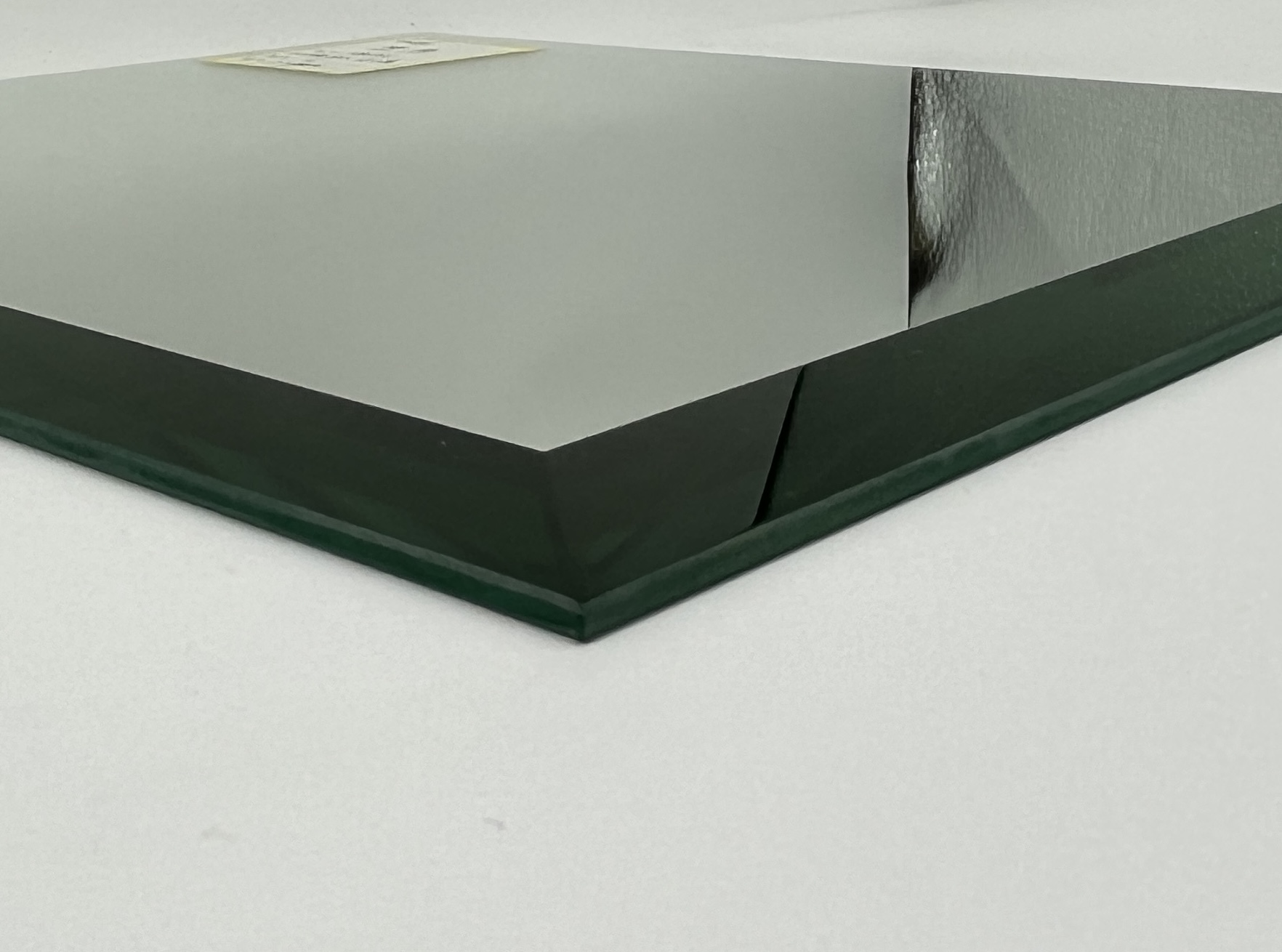

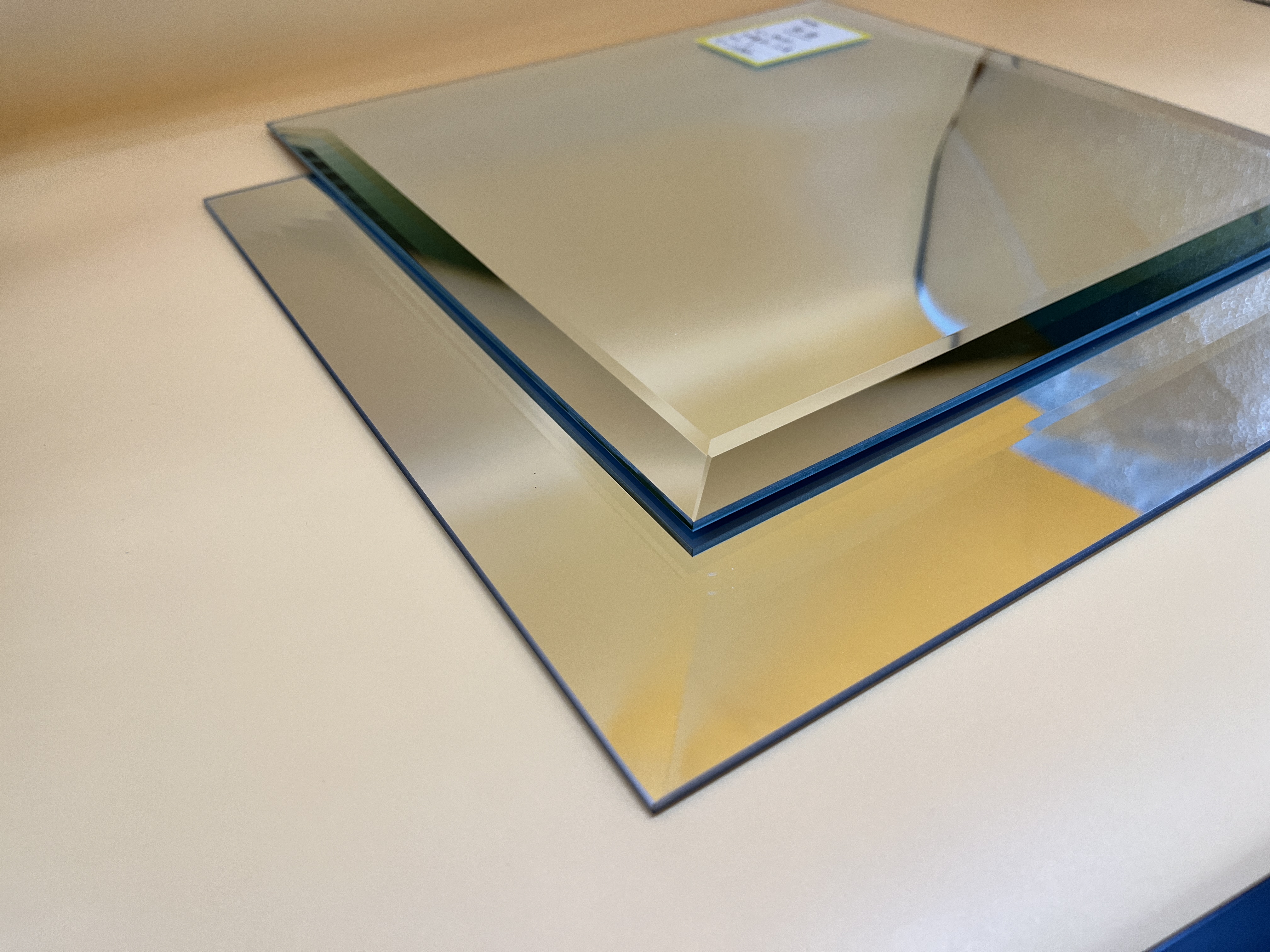

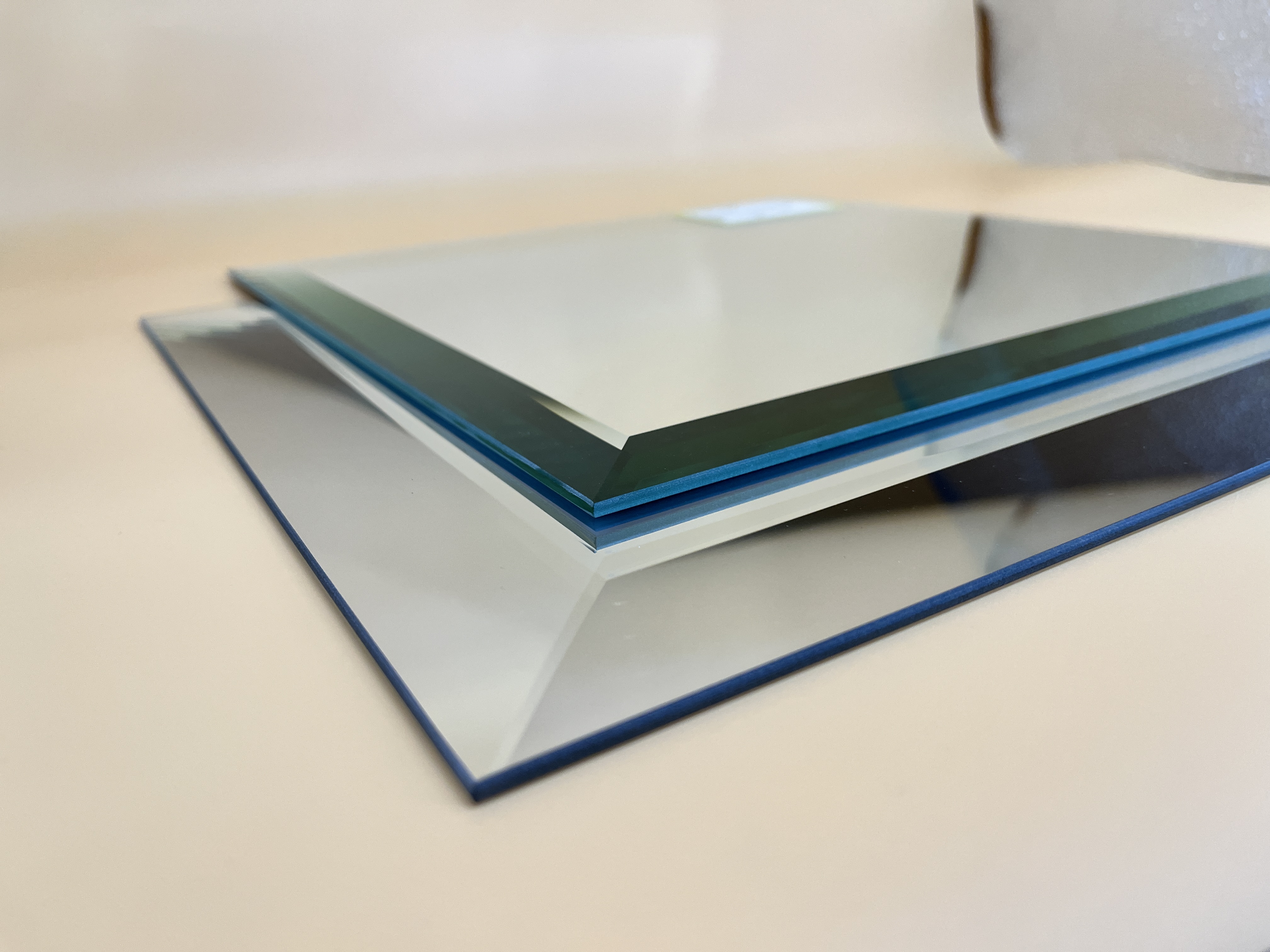

斜边最大宽度 Bevel width | 40mm |

角度 Bevel angle | 3-30° |

重量 Weight | 3800kg |

电压 Voltage | 220V,380V,415V/50Hz,60Hz for option |

磨头数量 Spindles | 9pcs |

总功率 Total power | 20.3kw |

尺寸 Dimension | 7700X1400X2500mm |

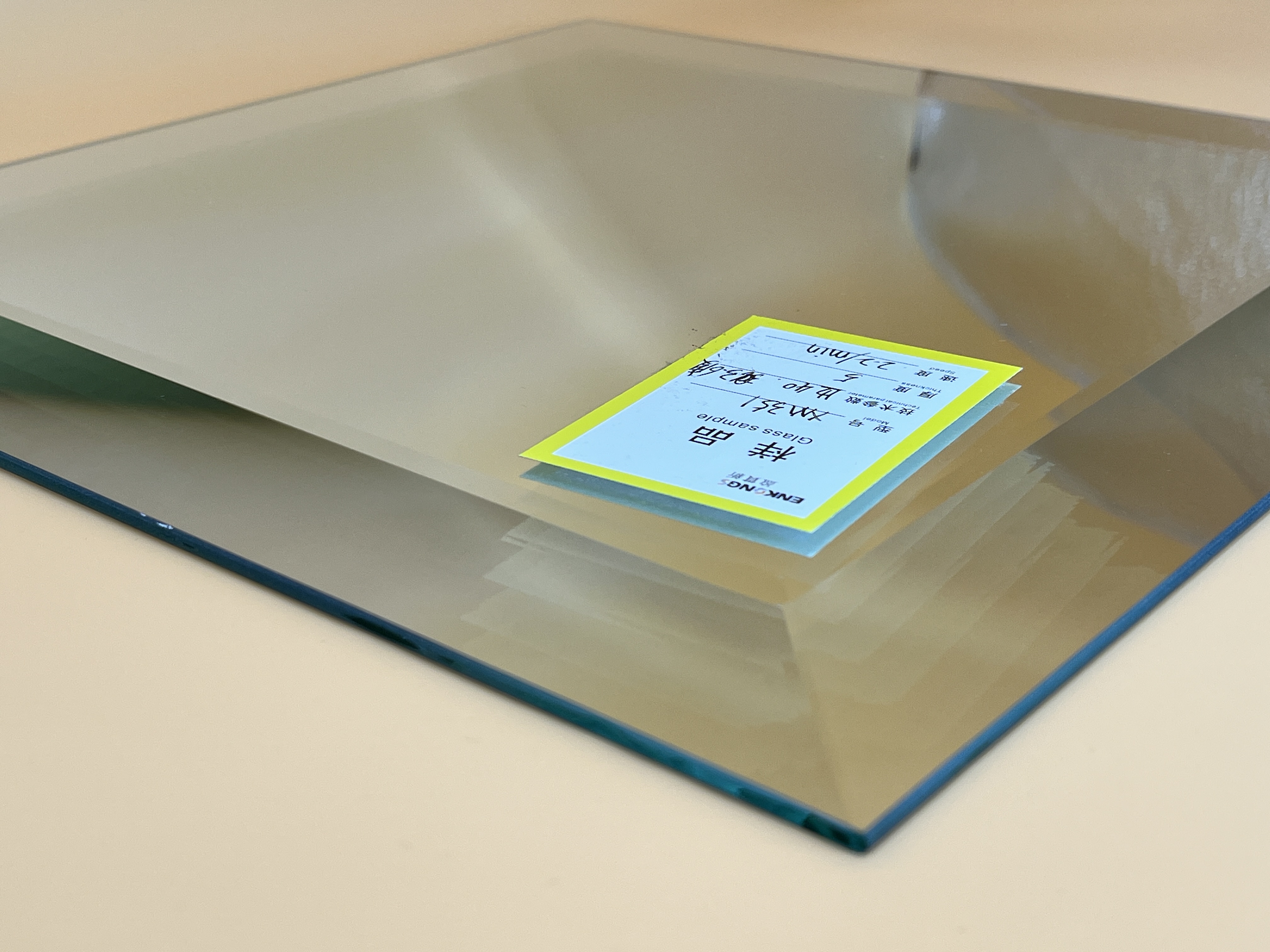

XM351、XM371 Glass Straight-line Beveling Machine is also used to process mosaic glass、inlay glass、spell mirror glass、craft glass ect.

In the realm of glass processing, glass edging machines are undoubtedly a critical technology. As a specialized piece of glass processing equipment, glass edging machines play an indispensable role in the production of glass products.

A glass beveling edging machine is a device used to grind the edges of glass. It utilizes precise control systems and efficient grinding processes to shape the glass edges to the required angles and shapes. This machine adds significant value to the glass processing process, enhancing the aesthetics of the products and their safety performance.

A glass bevel edger is a type of glass edging machine specifically designed for beveling the edges of glass. By beveling the edges, the glass becomes smoother and safer to handle. Glass bevel edgers are widely used in various fields such as glass doors and windows, glass curtain walls, and glass furniture.

Glass mirrors bevelling equipment is designed for bevelling the edges of glass mirrors. Glass mirrors are widely used in daily life, including bathroom mirrors and dressing table mirrors. With the help of this equipment, the edges of glass mirrors become more aesthetically pleasing and safe, improving the overall quality of the product.

A bevel edge glass machine is a device used to grind the bevel edges of glass. The bevel treatment adds an elegant and stylish touch to the glass edges, which are widely used in glass doors and windows, glass curtain walls, and other fields. This machine not only enhances the aesthetics of the glass products but also improves their safety performance.

An edger machine is a general term for glass edging machines, encompassing all the types mentioned above. As a professional glass processing equipment, the edger machine holds a pivotal position in the glass product production process.

Glass edging machines have the following main features:

High Efficiency: Glass edging machines use advanced grinding technology to complete the grinding of a large number of glass edges in a short time, improving production efficiency.

Precise Control: Glass edging machines have precise control systems that can accurately control parameters such as grinding angles and speeds, ensuring the stability of the grinding effect.

Safety and Environmental Protection: The design of glass edging machines is enclosed, effectively preventing glass fragments from flying and ensuring the safety of operators. Additionally, the dust and wastewater produced during the grinding process are treated effectively, meeting environmental protection requirements.

Wide Application: Glass edging machines are suitable for various types of glass processing, such as flat glass, tempered glass, and laminated glass, meeting the needs of different fields for glass products.

With the continuous development of the glass processing industry in our country, the market prospect for glass edging machines is broad. In the future, glass edging machines will continue to maintain their characteristics of efficiency, precision, safety, and environmental protection, contributing to the development of the glass processing industry. At the same time, glass edging machine enterprises in our country will also continue to innovate, enhancing product competitiveness and helping the glass processing industry to step onto the world stage.