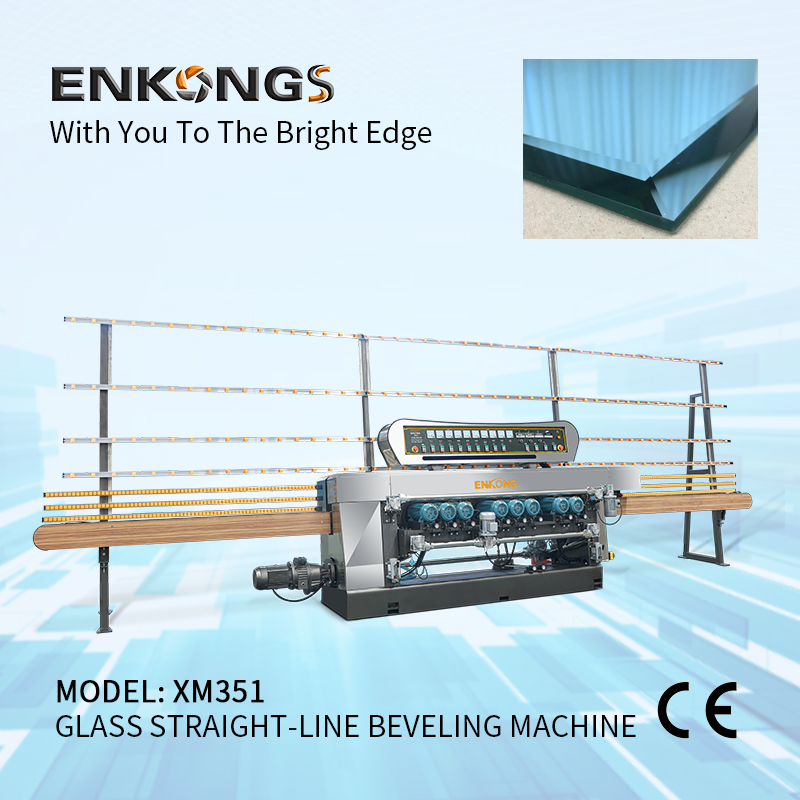

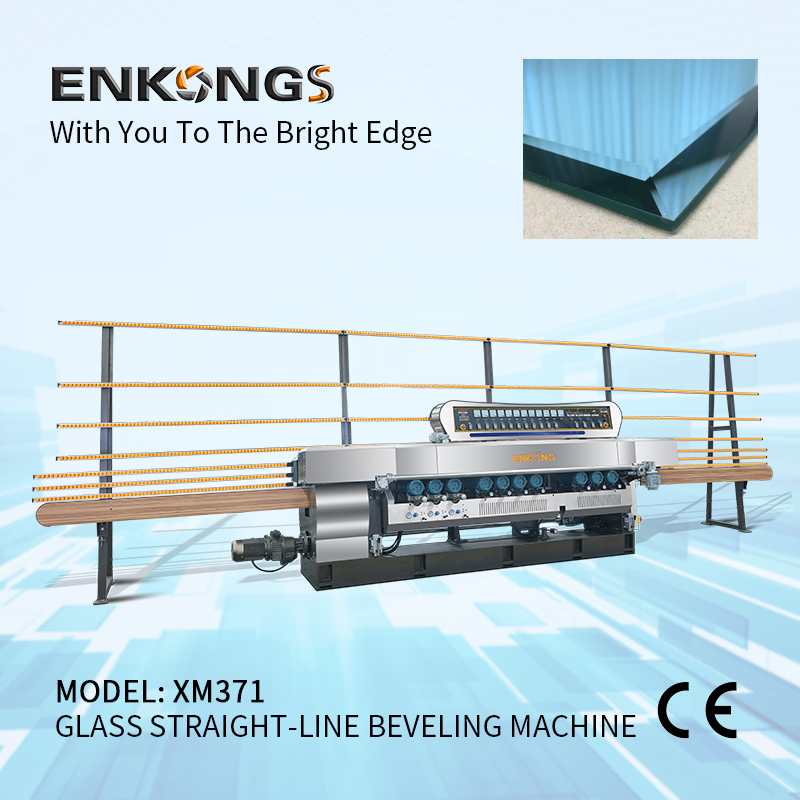

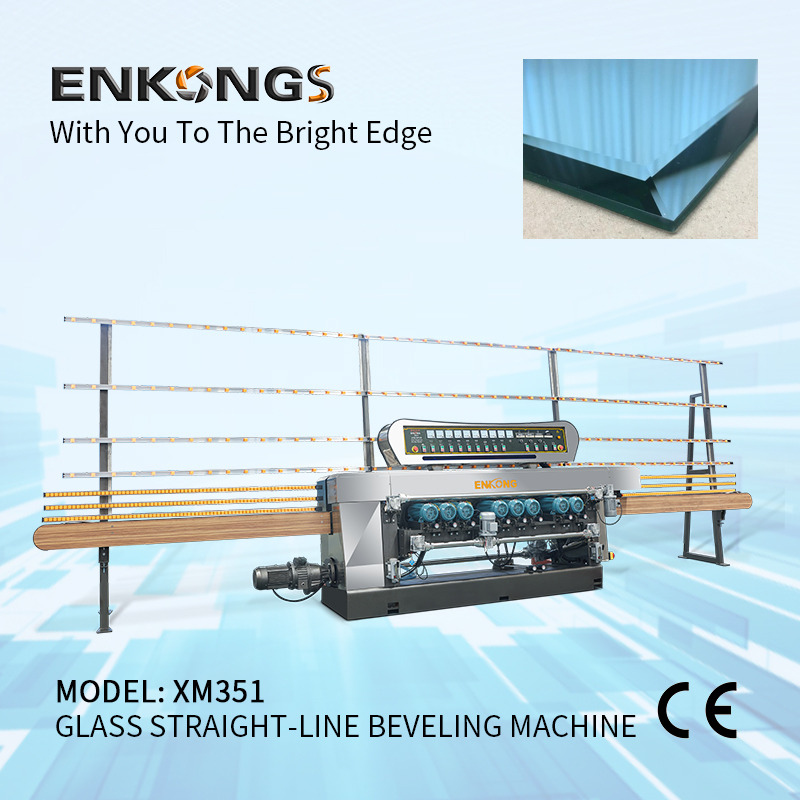

【Custom model, price is for reference only】

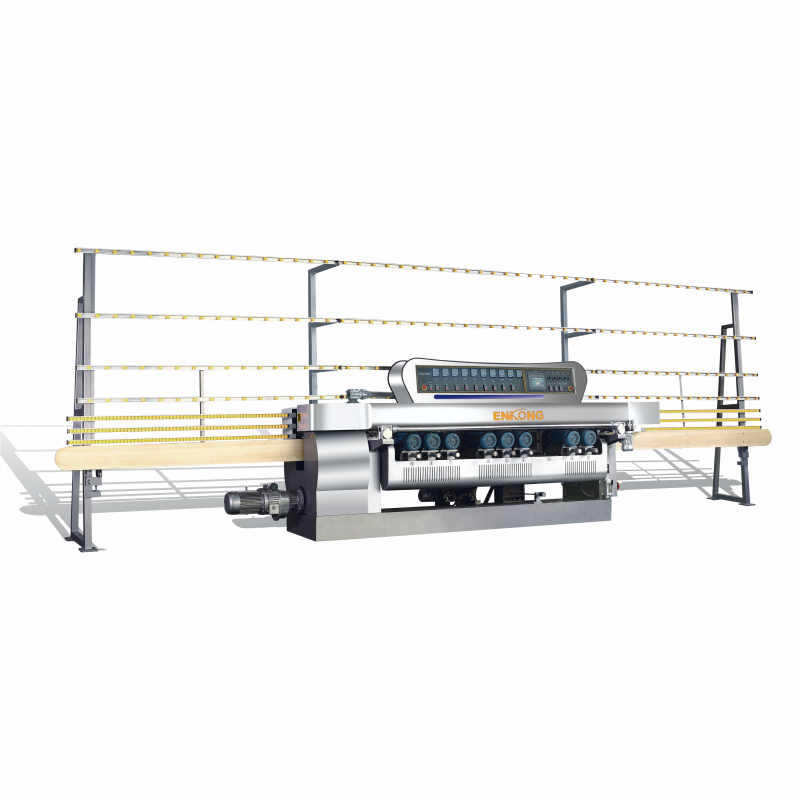

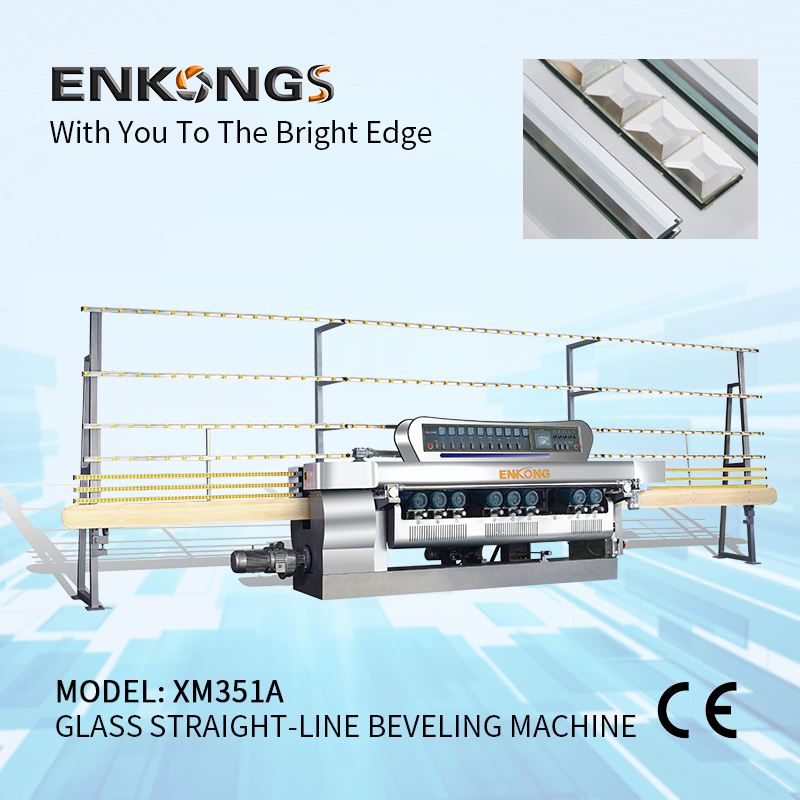

ENKONGS' straight line beveling machines equipped with advanced research and development technology, to ensure accurate and efficient glass grinding. With strong production capacity, it can handle large quantities of glass grinding tasks. It has reliable performance and high customer satisfaction.

Send Email

More