The selection of a glass edging machine is a critical decision for any manufacturer or service provider working with glass products. The machine's performance can significantly impact the quality of the final product, as well as the efficiency and cost of production. To ensure that you make an informed choice, several factors must be carefully considered when selecting a glass edging machine for a specific application. This article will explore these factors in detail and provide guidance on how to make the right decision for your business.

### 1. Application and Production Volume

The first step in choosing a glass edging machine is to consider the specific application for which the machine will be used. Different machines are designed to handle different types of glass and have varying levels of automation and precision. For example, some machines are better suited for straight-line edging, while others are designed for more complex shapes and patterns.

In addition to the type of glass, the production volume is another crucial factor to consider. High-volume production requires a machine that can handle a large number of pieces efficiently, while low-volume or custom work may require a more flexible and versatile machine that can handle smaller batches or one-off pieces.

### 2. Precision and Accuracy

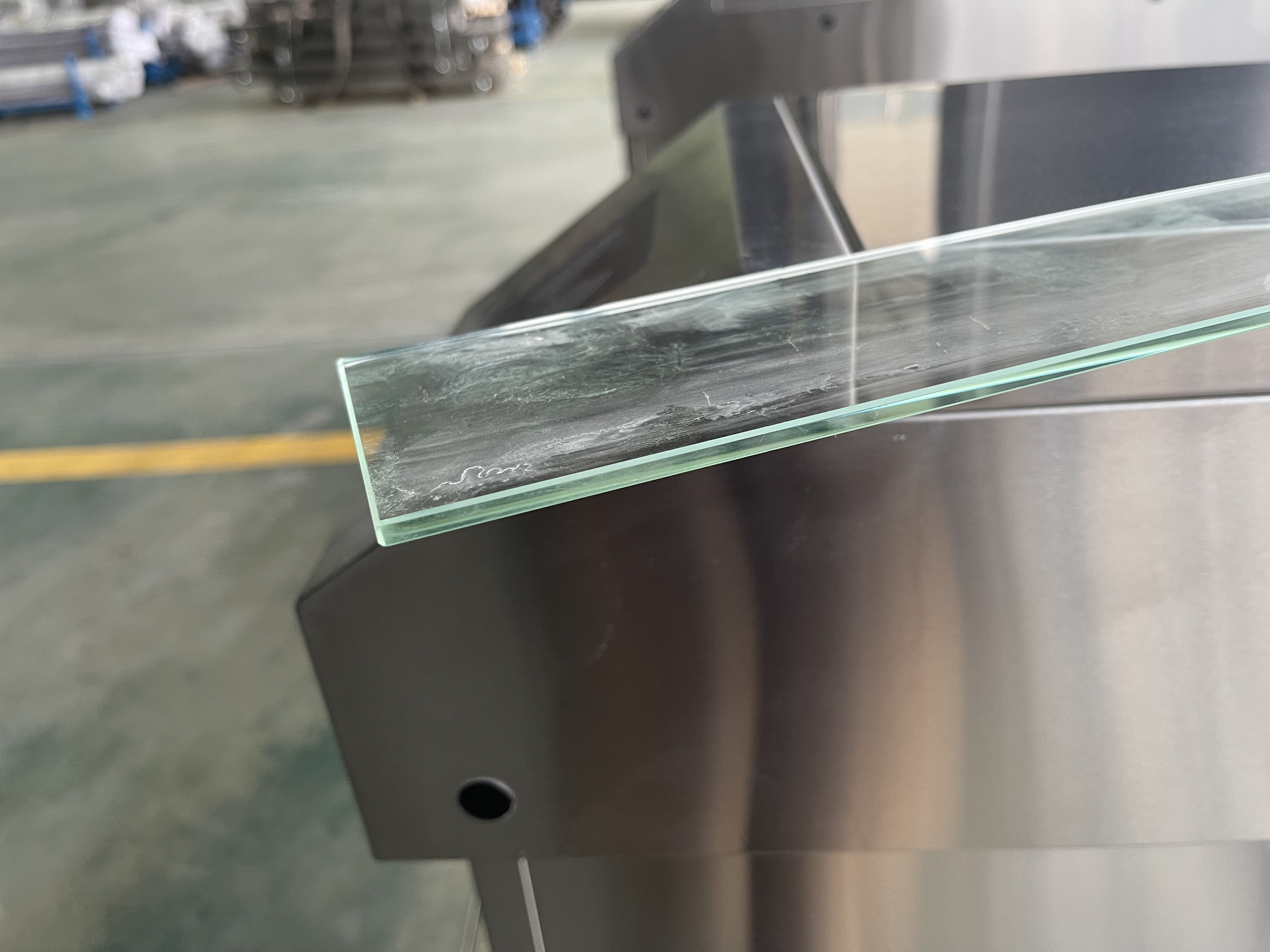

The precision and accuracy of the glass edging machine are critical for ensuring a high-quality final product. Precision refers to the machine's ability to consistently produce edges of the same dimensions and shape, while accuracy refers to how closely the final product matches the desired specifications.

To assess the machine's precision and accuracy, consider factors such as the machine's ability to handle various glass thicknesses, its repeatability, and its ability to produce tight tolerances. You may also want to consider machines with built-in quality control features, such as sensors that detect variations in edge quality or thickness.

### 3. Automation and Ease of Use

The level of automation in the glass edging machine can significantly impact the efficiency and productivity of your operation. Fully automated machines can handle multiple pieces simultaneously, reducing the need for manual intervention. However, they may require a higher initial investment and may not be suitable for all applications or production volumes.

On the other hand, semi-automatic or manual machines may be more affordable and suitable for smaller batches or one-off pieces. However, they may require more operator attention and may not be as precise or efficient as fully automated machines.

When considering automation, it's also important to consider the ease of use of the machine. A user-friendly interface and intuitive controls can make it easier for operators to learn and use the machine effectively, reducing the risk of errors or downtime due to operator confusion.

### 4. Safety and Compliance

Safety is always a top priority when working with glass, and the glass edging machine must comply with relevant safety standards and regulations. Look for machines that have been certified by reputable organizations such as CE (Conformité Européenne) or UL (Underwriters Laboratories). These certifications ensure that the machine meets specific safety requirements and can help you comply with local regulations.

In addition to safety certifications, consider factors such as the machine's enclosure design (e.g., whether it has a safety shield or enclosure to protect operators from flying glass), emergency stop buttons, and other safety features. These features can help prevent accidents and injuries in the workplace.

### 5. Maintenance and Support

The maintenance requirements and support provided by the manufacturer are essential considerations when choosing a glass edging machine. Machines that require frequent maintenance or repairs can be costly and time-consuming, impacting your productivity and profitability. Look for machines with easily accessible parts that can be replaced quickly, as well as machines that have a long lifespan and low downtime.

In addition to maintenance requirements, consider the level of support provided by the manufacturer. A reputable manufacturer should offer comprehensive training, technical support, and spare parts availability to ensure that your machine runs smoothly and efficiently over time.

### 6. Cost and Budget

Cost is always a critical consideration when making any purchase decision, including a glass edging machine. However, it's important to remember that choosing a low-cost machine may not always be the most cost-effective solution in the long run. Consider factors such as the machine's lifespan, energy efficiency, and overall productivity when making your decision.

A well-maintained and efficient machine can save you money in the long run by reducing downtime, increasing productivity, and improving the quality of your final product. In contrast, a low-quality or poorly maintained machine may require frequent repairs or replacements, increasing your overall costs.

### 7. Warranty and After-Sales Service

A good warranty and after-sales service can provide peace of mind when choosing a glass edging machine. Look for manufacturers who offer extended warranties on their machines and provide ongoing support after the initial sale. This support can include regular maintenance checks, troubleshooting assistance, and training for new operators or staff members.

An extended warranty can provide additional protection against unexpected repairs or malfunctions, while after-sales service can help ensure that your machine runs smoothly over time and meets your changing needs as your business grows or changes.

### Conclusion

Choosing the right glass edging machine for your specific application requires careful consideration of several factors, including application and production volume, precision and accuracy, automation and ease of use, safety and compliance, maintenance and support, cost and budget, warranty and after-sales service. By carefully evaluating these factors and considering your unique needs and requirements, you can select a glass edging machine that meets your business goals and delivers high-quality results over time