In a world where aesthetics merge with uncompromising functionality, the true mark of glass craftsmanship lies hidden in its edges. Modern glass processing machinery has elevated this critical finishing stage from an afterthought to a core competitive advantage. At the forefront stand sophisticated glass edging machines and versatile glass grinding machines, redefining what’s possible in workshops committed to excellence, speed, and safety.

The Imperative of Impeccable Edges

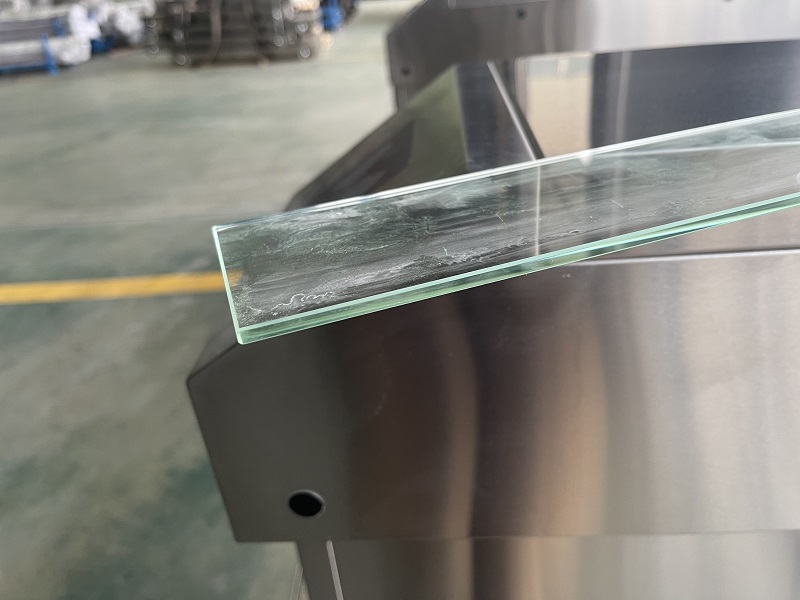

Glass transcends mere material—it’s an experience. Sharp, uneven, or micro-chipped edges shatter that experience, introducing safety hazards, compromising structural integrity, and diminishing visual appeal. A precision-engineered glass edging machine systematically eradicates these flaws. Through controlled abrasion and polishing sequences, it transforms vulnerable glass perimeters into resilient, smooth, and optically perfect boundaries. For sectors where safety is paramount—architectural glazing, automotive components, or public installations—a high-performance glass processing machine isn't just equipment; it's your first line of quality assurance.

Beyond Perimeter Perfection: The Grinding Advantage

While dedicated glass edging machines excel at shaping flawless boundaries, advanced glass edging machines deliver unparalleled versatility. These technological powerhouses handle complex tasks beyond simple edging:

Calibrating thickness variations across large panels

Removing surface imperfections and scratches

Preparing glass for laminating or tempering

Shaping intricate contours and curves

This multi-functional capability consolidates workflows. Why invest in separate units when one robust glass grinding machine can manage diverse tasks with robotic consistency? Integrating such a capable glass processing machine streamlines operations, reduces floor space requirements, and maximizes ROI.

Engineering Efficiency into Every Cycle

Time lost is profit forfeited. Automated glass edging machines revolutionize production timelines. Features like programmable CNC controls, multi-head configurations, automatic loading/unloading systems, and high-speed spindles slash processing cycles dramatically. Imagine running complex ogee edges on architectural glass panels while simultaneously grinding flat polish edges on shower doors—all unattended. A state-of-the-art glass grinding machine makes this possible, translating to:

40-70% faster job completion

Reduced labor costs and dependency

Capacity to handle surge orders and complex contracts

Lower per-unit operational costs

The productivity surge delivered by a modern glass processing machine often yields a remarkably swift return on investment.

Consistency: The Cornerstone of Reputation

Inconsistent quality erodes trust. Manual finishing inevitably introduces variations—operator fatigue, technique differences, environmental factors. Computer-controlled glass edging machines eliminate this variability. Once parameters for a specific edge profile (chamfer, pencil, bullnose) are programmed, every single piece emerges identical, batch after batch. This glass processing machine-driven consistency:

Ensures uniform quality across large projects

Meets stringent international safety standards

Reduces rejection rates and costly rework

Builds brand reputation for reliability

A precision glass grinding machine becomes your silent brand ambassador, guaranteeing that "flawless" defines every product bearing your name.

Safeguarding Your Greatest Assets: People

Traditional glass grinding presents significant hazards: silica dust inhalation, laceration risks, repetitive strain injuries, and noise exposure. Next-generation glass processing machinery embeds safety into its core design:

Fully enclosed grinding chambers with integrated HEPA filtration

Automated material handling minimizing operator contact

Water-fed operations suppressing hazardous airborne dust

Emergency stop systems, safety interlocks, and light curtains

Ergonomic interfaces reducing physical strain

Investing in a modern glass edging machine or comprehensive glass grinding machine demonstrates a proactive commitment to workplace safety, potentially lowering insurance premiums while fostering a healthier, more motivated workforce.

Where Precision Meets Diverse Demands

The impact of advanced glass grinding machines spans global industries:

Architecture & Engineering: Skyscrapers, curtain walls, structural glass floors, and frameless balustrades demand code-compliant, perfectly finished edges. A heavy-duty glass edging machine is non-negotiable.

Automotive & Aerospace: Windshield edges, mirror housings, and cabin partitions require defect-free grinding for safety and aesthetics. Precision glass processing machines deliver.

High-End Furniture & Retail: Bevelled display cases, luxury tabletops, and decorative panels need jewelry-like edge quality achievable only by advanced glass grinding machines.

Solar & Renewable Energy: Photovoltaic panel cover glass requires chip-free, polished edges to prevent micro-cracking and ensure longevity.

Electronics & Appliances: Touchscreen cover glass, oven doors, and refrigerator shelves demand optically clear, tactilely smooth edges.

Choosing Your Strategic Edge Partner

Selecting the optimal glass edging machine or glass grinding machine demands careful analysis:

Profile Complexity: Can it handle your required edge types (straight, mitre, complex shapes)?

Throughput & Automation: Does it offer automated loading/unloading? Multi-head processing?

Material Flexibility: Does it process varying thicknesses (3mm-25mm+), laminated, or tempered glass?

Control & Software: Is the CNC system intuitive? Can it store hundreds of profiles?

Durability & Support: Is it built for industrial duty cycles? What’s the manufacturer’s service reputation?

Prioritize glass processing machines offering scalability and compatibility with future Industry 4.0 integrations.

The Future-Proof Workshop: Intelligence & Adaptability

The evolution of glass processing machinery continues relentlessly. Leading manufacturers integrate:

AI-Powered Predictive Maintenance: Sensors anticipate spindle or belt failures before downtime occurs.

Energy Recovery Systems: Capturing and reusing energy from braking and operations.

Enhanced Connectivity: Real-time production monitoring and remote diagnostics via IoT.

Advanced Abrasive Technologies: Longer-lasting diamond tools and optimized cooling systems.

Investing in a modern, upgradable glass edging machine or adaptable glass grinding machine positions your business at the cutting edge, ready to embrace emerging opportunities.

The Sharp Edge of Competitive Advantage

Profitability in glass fabrication increasingly resides in minimizing waste, maximizing throughput, and commanding premium prices through demonstrable quality. A high-performance glass grinding machine achieves this by reducing breakage, eliminating rework, and enabling faster job turnover. When paired with a dedicated glass edging machine for specialized tasks, your workshop gains unparalleled flexibility to tackle diverse markets – from monumental architectural projects to intricate artisanal commissions.

Elevate Your Craft, Define Your Legacy

Your machinery speaks volumes before a single word is uttered. Clients witnessing a workshop equipped with advanced glass processing machines recognize a commitment to excellence. They understand that your investment in precision glass edging machines and robust glass grinding machines directly translates to the integrity, safety, and beauty of their vision realized in glass.

In an industry where the margin between success and failure can be as thin as a glass edge, don't just participate—dominate. Harness the transformative power of precision edge technology. Let your work speak through its flawless finish, project after project, proving that in the world of glass, perfection is not an accident—it’s engineered.