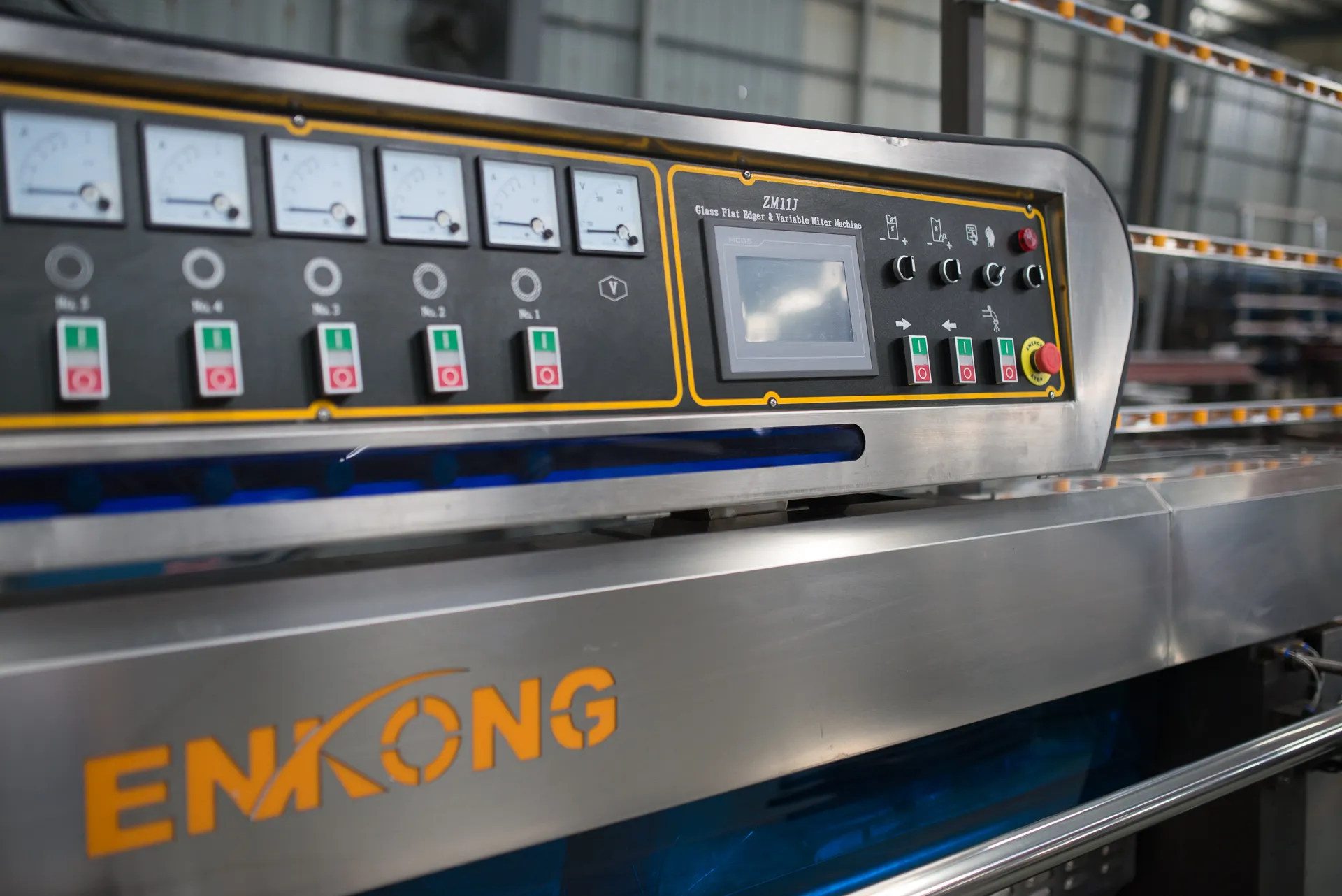

ZM11J glass flat edger&variable miter machine is suitable for mitering glass from a 0 - 60 degree angle. The machine is designed to coarse/fine grinding and polishing flat glass. Big pitch chain gear is adopted for conveying which makes a stable conveying and high precision process.The input/output ends can be adjusted from 90 degree to 45 degree and this is realized by lifting guide rail but without need of adjusting grinding wheels.It is suitable for professional furniture, doors, windows, kitchen, craft, construction glass grinding. WhatsAPP+86 188 2308 1140 Email:jmek@enkongs.net

The glass fabrication enterprise is at the cusp of a big transformation, pushed through the mixing of smart automation and precision engineering. At its core, the answer seamlessly connects the preliminary section treated through a superior glass cutting machine with the very last completing carried out through a complicated automatic glass machine. The number one goal is to continuously and successfully produce perfect flat polished edge glass that meets the maximum stringent architectural and indoors layout standards.

The adventure of a pitcher panel starts offevolved with the crucial first step of shaping, a site completely depending on the talents of a current glass cutting machine. The precision at this preliminary level is non-negotiable, because it units the foundational geometry for all next completing processes. The cutting-edge glass cutting machine models, frequently geared up with CNC controls and imaginative and prescient systems, make sure that each rating and wreck is done with microscopic accuracy. When a panel is flawlessly cut, it lets in the following automatic glass machine to carry out its characteristic at top performance with no need to accurate for earlier errors, thereby setting up a sturdy basis for the whole manufacturing line and making sure the dependable introduction of top rate flat polished edge glass.

Following the suitable reducing operation, the glass panel is transported to the coronary heart of the completing line: the Orion automatic glass machine. Its intuitive interface lets in for the fast choice of numerous side profiles, with the famous flat polished edge glass specification being a trendy and without problems potential option. Every factor of this automatic glass machine is ruled through state-of-the-art software program that video display units variables like pressure, velocity, and coolant flow, making certain that every panel rising from the road possesses a consistent, notable finish, geared up for fast set up or similarly assembly.

The maximum visually and tactilely considerable final results of this incorporated system is the impeccable flat polished edge glass. Achieving this pristine end result continuously calls for gigantic mechanical balance from the automatic glass machine. The new technology of equipment counteracts this with a closely strengthened chassis and precision-guided linear movement systems, making sure the glass is offered to the sprucing modules with absolute consistency. This engineering rigor ensures that the required flat polished edge glass isn't always simply a opportunity however a repeatable, assured preferred for each unmarried panel that passes thru the machine.

The complete capability of this superior automatic glass machine is unlocked while it's far digitally and bodily incorporated with the upstream glass cutting machine. In the sort of configured line, a virtual process record from a CAD machine can direct the preliminary glass cutting machine to optimize sheet format and execute complicated shapes with precision. The reduce portions are then mechanically routed to the automatic glass machine, which gets the corresponding virtual commands to use the ideal aspect profile—whether or not a easy flat polish or a extra complicated ogee—for every specific part. This seamless information go with the drift removes guide transcription mistakes and setup delays, growing a definitely agile production cell. This direct hyperlink among the glass cutting machine and the completing unit is the cornerstone of cutting-edge, lean glass fabrication, permitting small batch sizes and just-in-time manufacturing with out sacrificing quality.

From a commercial enterprise perspective, the funding in a totally incorporated gadget proposing a high-give up glass cutting machine and a sturdy automatic glass machine can provide a compelling go back on funding. The dramatic discount in guide exertions for sharpening and the near-removal of waste because of facet defects at once decrease manufacturing costs. The cappotential to reliably promise and supply ideal flat polished edge glass lets in fabricators to stable extra rewarding contracts withinside the high-give up architectural and indoors layout sectors. Furthermore, the performance profits from linking a high-pace glass cutting machine at once to a bendy automatic glass machine translate into shorter lead instances and extended throughput capacity.

In conclusion, the trajectory of the glass enterprise is unmistakably pointed closer to completely incorporated, digitally controlled manufacturing lines. The improvement of structures just like the Orion Series highlights the essential significance of the handoff among a precision glass cutting machine and a flexible automatic glass machine. The relentless cognizance on reaching ideal flat polished edge glass is an immediate reaction to marketplace needs for advanced aesthetics and performance. They can be able to coping with the maximum complicated and stressful projects, turning in impeccable flat polished edge glass with an performance and consistency that changed into formerly unimaginable, thereby shaping the very skylines and areas of the future.