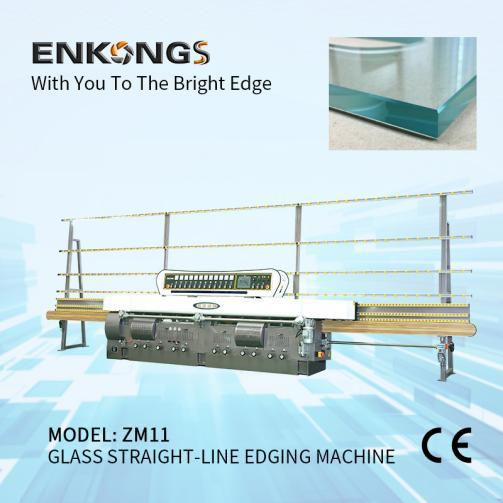

Basic features of glass straight-line edging machine:

1. The glass straight-line edging machine series adopts stainless steel appearance, simple and beautiful

2. The front and rear reinforcement castings such as beams, columns, pallets, bases and other machined parts are subjected to secondary heat treatment. And the machining processes such as turning, milling, planing, grinding, and boring are carried out in the CNC gantry machining center. That can reduce the cumulative tolerance of the whole machine assembly , and then improve the grinding precision.

3. The front and rear chain plates adopt double chain and hanging structure, the clamping force is constant, and the loading and unloading is convenient.

4. The input guide rail has synchronous lifting and lowering, which is convenient to adjust the grinding amount.

5. The front and rear chamfered motor carriages use linear sliding friction guide rails, and the advance and retreat are smooth.

6. The No.9 grinding wheel can be equipped with wool wheel and CE-3 polishing wheel for flat bottom edge polishing.

7. Operation mode: manual, digital display, PLC+touch screen+pneumatic polishing.

8. This machine can be upgraded and equipped with automatic lifting adjustment of grinding wheel.

The daily maintenance of the glass straight-line edging machine is as follows:

1. After working every day, clean the inside and outside of the machine.

2. The grinding head of the glass linear edging machine should be checked and replaced at any time.

3. The gear oil should be replaced after the transmission reducer of the glass linear edging machine works for 1000 hours. The oil amount should be kept in the middle of the oil mirror, but not excessive. It is recommended to use No. 150 industrial gear oil.

4. The synchronous pulley and guide groove, gear, screw, sprocket and various transmission bearings should be kept lubricated every day.

5. ① The joint surfaces of the front and rear pressure plates and the guide rails should be lubricated frequently. Otherwise the normal service life of the machine will be affected due to the premature wear of the front and rear pressure plates and the working surfaces of the guide rails. Although some models have automatic lubricating device, it is necessary to check whether the lubrication pipeline is unblocked frequently; ②The clamping force should be appropriate when clamping the glass, too loose will affect the grinding quality, and too tight will increase the load of the machine, which is easy to produce The phenomenon of shaking and crawling, and it is easy to break the glass when grinding thin glass. The clamping force can be tested by clamping a piece of slightly larger glass on the machine, that is, clamping the glass in the middle of the machine, and pulling the glass with both hands when the machine is stopped. It is appropriated to adjust the clamping force to just when the two hands cannot move it.

6. Although the grinding wheel lubricating cooling water of the glass linear edging machine is recycled, it also needs to be replaced continuously, and the cleanliness should be maintained asmuch as possible to ensure the polishing effect of glass edging.