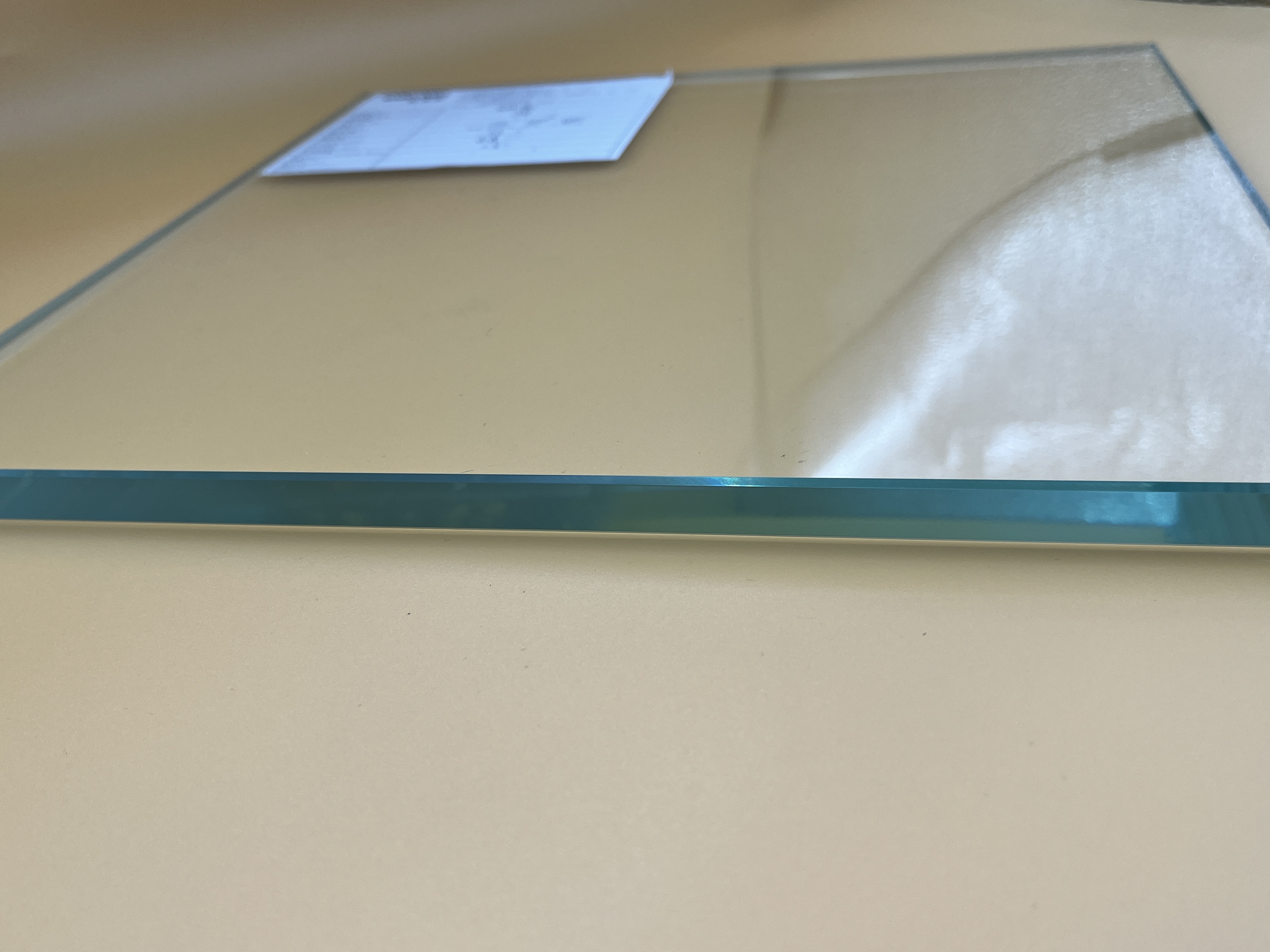

ENKONGS' SM24-Glass Double Straight Line Cutting Machine is a fully automatic, high-speed precision grinding machine used in the glass industry. SM24 High-Speed Glass Double Edging Machine is capable of grinding both edges of the glass simultaneously, ensuring a smooth and precise finish. High-Speed Glass Double Edging Machine is suitable for architectural glass/household glass/furniture glass.

The global demand for high-precision, aesthetically flawless glass in architectural applications, particularly doors and windows, continues its relentless ascent. Fabricators face immense pressure to deliver complex, customized units faster, with impeccable edge quality, while managing escalating labor costs and stringent safety requirements. Addressing this critical industry challenge head-on, a new generation of glass double straight line edging machine technology has emerged, setting unprecedented benchmarks in productivity, precision, and versatility. This innovation isn't merely an incremental upgrade; it represents a paradigm shift in how door and window glass processing machine facilities operate. By integrating advanced dual-head processing capabilities directly into the glass double edger core design, manufacturers can now simultaneously finish two parallel edges of a glass pane in a single, streamlined pass. This eliminates the traditional bottleneck of sequential edging, drastically reducing cycle times and labor dependency. The inherent efficiency of this glass double straight line edging machine design directly translates to lower per-unit production costs and enhanced competitiveness, especially crucial for high-volume glass double edger operations producing vast quantities of insulated glass units, laminated panels, and tempered sections requiring pristine straight edges.

ENKONGS' glass double edger leverages cutting-edge engineering to deliver unparalleled edge consistency and surface quality. At its heart lies a robust, vibration-damped structure ensuring absolute stability during high-speed operation. Precision linear guides and high-torque servo motors drive independent spindle carriages, each equipped with multi-axis grinding heads capable of handling a comprehensive range of edge profiles – from crisp straight polishes and delicate pencil rounds to sophisticated bevels and intricate miters – all essential for modern door and window glass processing machine outputs. Sophisticated CNC controls manage every parameter: grinding pressure, coolant flow, and traverse speed, all meticulously calibrated for specific glass thicknesses and desired finishes. Integrated optical measurement systems, often utilizing laser or CCD technology, can verify edge dimensions and angles in real-time, feeding data back to the control system for closed-loop adjustments, ensuring every piece leaving the glass double edger meets exacting geometric tolerances demanded by high-end architectural glazing projects. This level of automation intrinsic to the modern glass double edger minimizes human error and maximizes yield.

The transformative impact of this advanced glass double straight line edging machine is most profoundly felt within the door and window glass processing machine ecosystem. For fabricators specializing in large volumes of standard-sized units – think expansive commercial curtain walls or high-output residential window lines – the machine’s ability to process two edges concurrently is revolutionary. Imagine doubling straight-line edging capacity without doubling floor space or operator headcount; this is the core proposition of the high-performance glass double edger. Furthermore, rapid changeover systems, often featuring automatic tool changers and recipe management software, allow seamless transitions between different glass thicknesses and edge profiles, making the glass double straight line edging machine exceptionally agile for handling mixed batches and custom orders. This flexibility is vital for modern door and window glass processing machine shops catering to diverse architectural specifications. Enhanced safety features, such as comprehensive guarding, automatic glass break detection, and emergency stop circuits integrated throughout the glass double edger, protect both operators and valuable glass substrates. Dust extraction systems efficiently capture grinding particulates, maintaining a cleaner workshop environment and protecting downstream processes within the door and window glass processing machine workflow, such as lamination or coating.

Beyond sheer speed and precision, the latest glass double straight line edging machine models incorporate intelligent features that elevate operational efficiency and predictability. Predictive maintenance algorithms analyze vibration and power consumption data from the glass double edger, alerting technicians to potential issues before they cause costly downtime – a critical advantage in a continuous door and window glass processing machine environment. Energy-efficient drives and optimized coolant recycling systems significantly reduce the operational footprint of the glass double straight line edging machine, aligning with growing sustainability mandates. User interfaces have evolved into intuitive touchscreen panels offering graphical visualization of the machining process, simplified recipe programming, and comprehensive diagnostic tools, reducing the skill threshold required for effective operation. This focus on smart technology transforms the glass double edger from a standalone tool into a data-rich node within a connected, intelligent glass double edger factory, enabling data-driven decisions for further optimization of the entire production chain.

The advent of this high-capacity, intelligent glass double edger signifies more than just a new product category; it represents the future trajectory of glass fabrication for the architectural sector. As building designs grow increasingly complex, featuring larger glass spans, more demanding aesthetic requirements, and tighter performance specifications for energy efficiency and safety, the pressure on glass double edger providers intensifies. The glass double edger, with its unmatched combination of dual-edge processing, sub-millimeter precision, advanced automation, and data intelligence, provides the essential foundation for fabricators to thrive in this competitive landscape. It empowers them to meet shorter lead times, handle intricate custom work profitably, ensure consistent quality essential for structural glazing applications, and optimize resource utilization. Investing in this next-generation glass double straight line edging machine technology is no longer merely an option for forward-thinking door and window glass processing machine manufacturers; it is rapidly becoming an imperative for survival and growth, setting the new standard for efficiency, quality, and technological sophistication in the global architectural glass industry. The dual-head revolution is here, reshaping the economics and capabilities of door and window glass processing machine production lines worldwide.