ENKONGS' ZM9 glass straight line polishing machine is designed for high-speed polishing, automatic glass machine is suitable for processing straight-line edge & 45°arrises of glass sheet with various size and thickness,and rough grinding, fine grinding, polishing of flat edge and grinding of bottom edge can be completed in one time. WhatsAPP+86 188 2308 1140 Email:jmek@enkongs.net

The realms of architectural and interior design are in a constant pursuit of perfection, characterized by clarity, precision, and an impeccable finish. At the core of this endeavor lies a fundamental yet intricately complex process: the transformation of raw, cut glass into safe, aesthetically pleasing, and functional components. GlasTech Innovations, a global leader in advanced manufacturing solutions, is proud to introduce the Luminaut Series—a new generation of fully automated glass processing machines designed to deliver the world's most consistent and flawless flat polished edge machine. The flat polished edge machine groundbreaking system signifies not merely an incremental enhancement but rather a fundamental reimagining of the entire grinding and polishing workflow.

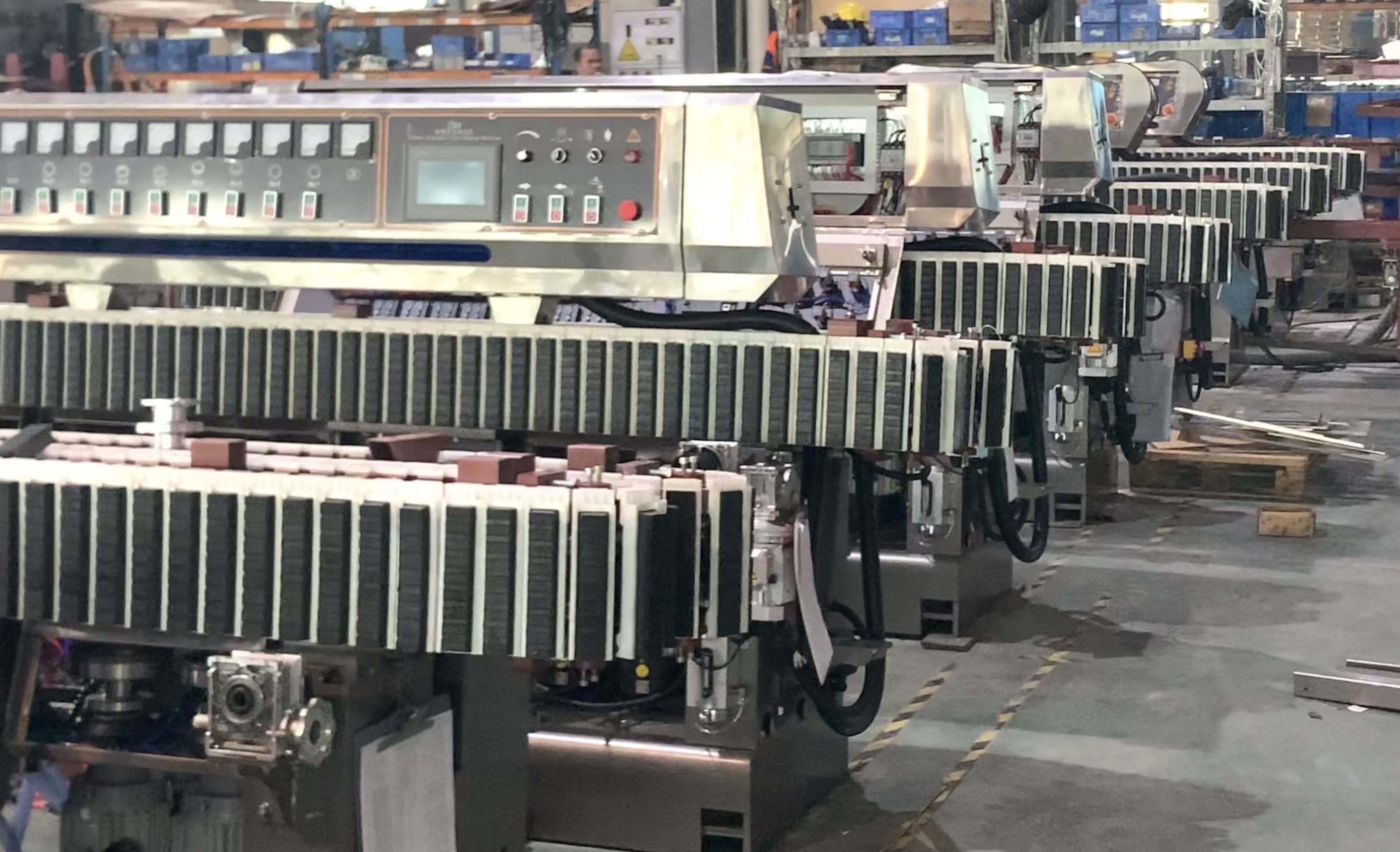

The primary objective behind the Luminaut Series was to address a persistent challenge faced by high-volume fabricators: achieving absolute consistency in edge work across thousands of individual pieces without compromising operational speed or flexibility. Traditional methods often involve multiple stages of semi-automated handling where the glass is transferred between different glass processing machine for rough grinding, fine grinding, and final polishing. Each transfer introduces potential inaccuracies along with risks for handling damage and workflow bottlenecks. The Luminaut automatic glass machine completely eliminates glass processing tools multi-stage transfer process. Automatic glass machine is envisioned as a singular, cohesive production cell—a closed-loop system wherein a raw, cut sheet of glass enters one end and emerges from the other as a finished product. The edges exhibit a pristine, optically perfect flat polished edge machine finish that was previously achievable only through extensive manual labor and meticulous inspection.

The core of the Luminaut's processing capabilities resides in its groundbreaking multi-axis robotic arm, which is equipped with a proprietary quick-change tool mounting system. This arm does not utilize a single universal tool; instead, it automatically selects from an integrated magazine of specialized glass processing machine tailored for specific tasks and grit sequences. The journey to a perfect flat polished edge machine begins with a robust diamond grinding wheel that glass processing tools shape the material and removes any irregularities. Subsequently, the machine autonomously transitions—without human intervention—to a series of progressively finer grinding heads, each meticulously engineered to eliminate scratches left by the preceding coarser tool. This automated tool-changing functionality is fundamental to the Luminaut's ingenuity, facilitating a continuous and uninterrupted processing cycle that maximizes efficiency while mitigating quality variances typically associated with manual tool changes.

Following the grinding sequence, the system seamlessly advances into the polishing phase. The robotic arm docks with the final grinding head and selects a high-performance polishing wheel from its comprehensive arsenal of glass processing machine. Glass processing machine' wheel works in conjunction with a continuous flow of specialized cerium oxide slurry to achieve what is renowned as an exceptional luminescent finish. The pressure, speed, and trajectory of the polishing arm are precisely regulated by a central computer that dynamically adjusts parameters based on both glass type and thickness. The outcome is an edge on flat polished edge machine that not only feels smooth to touch but also exhibits brilliant crystalline clarity. Flat polished edge machine enhances the overall aesthetic appeal of the glass itself and transforming what could be seen merely as functional necessity into an attractive feature.

What actually distinguishes this automatic glass machine with any other machine on the market is automatic glass machine' integrated adaptive learning system. During the process of grinding and polishing, a network of sensors constantly monitors a series of parameters: engine tissue, tool wear, viscosity and sludge temperature. These data are returned to the central processing unit in real time. If the system detects that specific glass processing machine begins to display wear and create a less perfect ending, automatic glass machine can automatically compensate by adjusting a little pressure, increasing polishing time or even signaling maintenance tools. This predictive capacity prevents glass production with sub-standard flat polished edge machine and turns the machine from a passive tool into an active and intelligent partner in the production process.

In short, Glastech's Luminaut -Roastech is not only a new factory device. Glass processing machine is a model change, a complete solution to redefine what is possible in the production of glass. By merging the accuracy of the robot with artificial intelligence and deep understanding of automatic glass machine behind the creation of a perfect flat polished edge machine, the company has created a system to set up a new worldwide reference. This automatic glass machine, with automatic glass machine' intelligent suite of glass processing machine, allows manufacturers to reach the quality, efficiency and consistency that previously unimaginable. It is not only a question about tracking the speed of the future industry; He took the initiative to create it, a perfect edge at the same time. Se -Ri Luminaut is available to order, with expected settings in the fourth quarter of this year.