The relentless pursuit of flawless edges isn't just an aesthetic goal; it's a fundamental requirement for safety, functionality, and market competitiveness in glass fabrication. Yet, many workshops remain tethered to outdated methods or underperforming equipment. Could the core of your bottleneck lie in the very glass processing machine designed to liberate your productivity? Specifically, is your current glass edging machine truly meeting the escalating demands for precision and efficiency, or is it quietly eroding your profit margins through slow cycles, excessive waste, and inconsistent results? What if the key to unlocking new levels of quality and throughput resided in re-evaluating your primary glass edging machine?

The evolution of the modern glass edging machine represents a quantum leap from rudimentary grinding practices. Today's sophisticated glass processing machine integrates advanced engineering to transform raw, potentially hazardous glass sheets into beautifully finished, perfectly safe components. The right glass grinding machine doesn't merely abrade an edge; it meticulously refines it to exacting specifications – straight, beveled, polished, or intricately shaped – with minimal supervision. Consider the daily reality: handling large, cumbersome sheets demands equipment that offers not just power, but also exceptional stability and user-friendliness. Does your existing glass edger provide the intuitive controls and robust construction needed to minimize operator fatigue and maximize output consistency? Or are you battling with finicky adjustments and frustrating downtime?

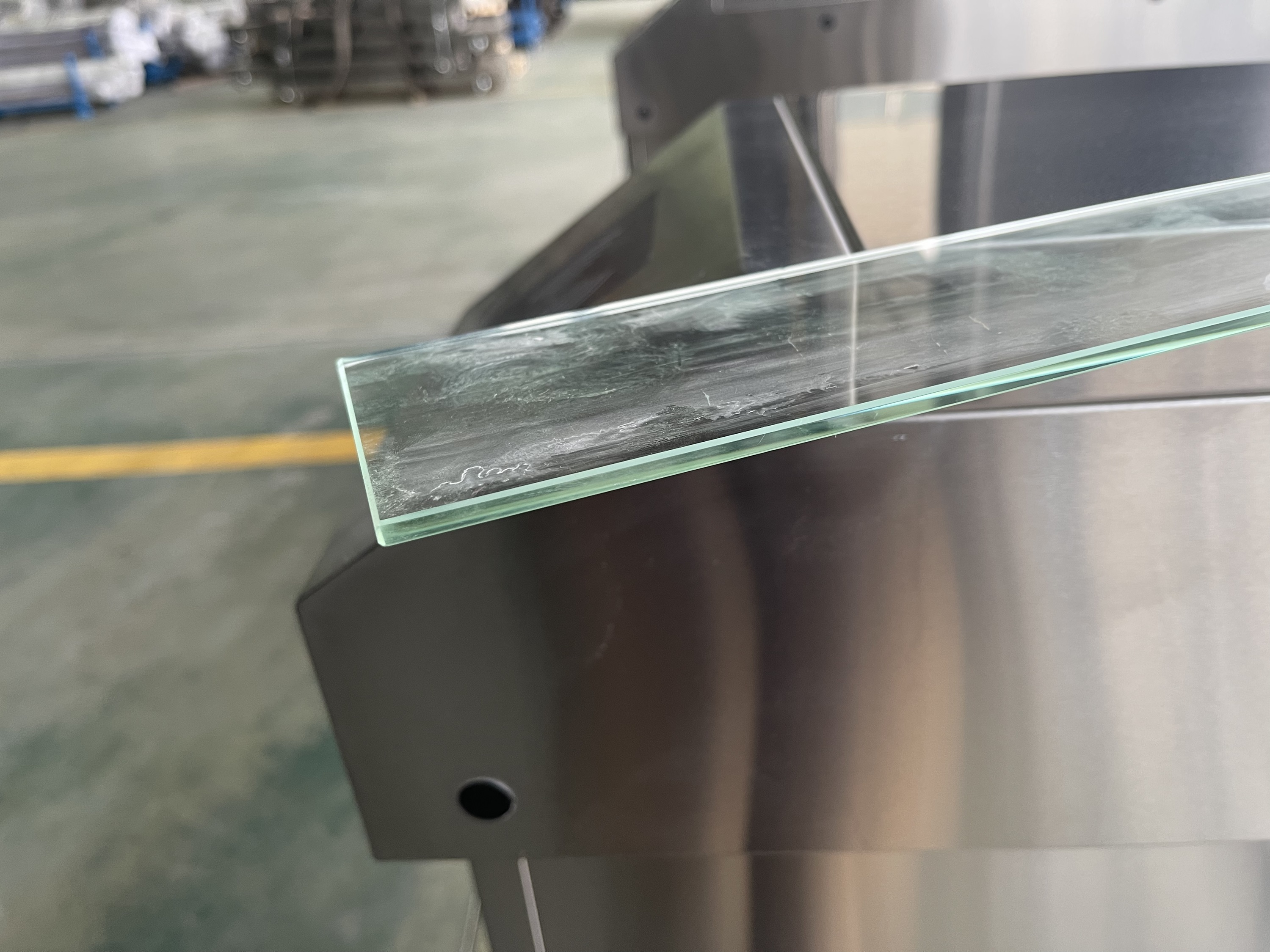

Precision is non-negotiable. A subpar glass grinding machine introduces costly variations – edges that aren't perfectly square, bevels with inconsistent angles, or polished finishes marred by waves or scratches. These defects lead directly to rejected pieces, wasted materials, and dissatisfied customers demanding reworks. Investing in a high-precision glass processing machine directly tackles this. Imagine a glass edging machine equipped with precision-ground spindles, vibration-dampening technology, and sophisticated feed mechanisms. Such a glass edging machine ensures every single piece, whether a simple straight edge or a complex pencil polish, meets identical, flawless standards batch after batch. Doesn't consistent, defect-free output sound like the foundation for a stellar reputation and repeat business?

Versatility is equally critical in today's dynamic market. Projects rarely involve just one edge type. Can your current glass edging machine seamlessly transition between different operations? A truly advanced glass processing machine is inherently adaptable. The ideal glass grinding machine allows for quick changeovers between wheels – perhaps switching rapidly from aggressive rough grinding to fine polishing, or configuring for a specific bevel angle. This flexibility means a single glass edger can handle diverse jobs: thick architectural panels demanding robust grinding, delicate decorative pieces needing a flawless polish, or custom shower enclosures requiring precise miters. Does your workshop possess this agility, or are you constrained by a machine that only handles a narrow range of tasks, forcing costly outsourcing or impractical workarounds?

Beyond the immediate quality improvements, the right glass processing machine delivers a compelling return on investment through dramatic efficiency gains. Time is money, especially on the shop floor. A slow, cumbersome glass grinding machine creates production logjams. Modern glass edging machine technology focuses intensely on optimizing cycle times. Features like programmable settings for different edge profiles, automatic feed systems that maintain consistent speed and pressure, and quick wheel dressing capabilities significantly reduce the time each piece spends on the machine. Think about the cumulative impact: faster processing means more jobs completed per shift, quicker turnarounds for clients, and the ability to take on larger volume contracts with confidence. Isn't it time your primary glass grinding machine became a driver of profit rather than a constraint?

Durability and ease of maintenance are often overlooked but vital factors. A poorly built glass processing machine becomes a money pit. Constant breakdowns, expensive part replacements, and lengthy service calls cripple productivity and inflate operating costs. A robust glass edging machine, engineered with high-quality components and designed for ease of service, offers long-term reliability. Look for a glass grinding machine built with a heavy-duty frame to withstand continuous operation, easily accessible service points for routine maintenance like belt changes or lubrication, and readily available spare parts. Minimizing unplanned downtime isn't just convenient; it's essential for maintaining workflow and meeting deadlines. Can your current glass processing machine claim this level of dependability?

Operator safety and ease of use are paramount. Glass handling carries inherent risks, and grinding operations produce dust and noise. A modern glass edging machine prioritizes the operator. Effective dust extraction systems integrated directly into the glass processing machine are crucial, protecting lungs and keeping the work environment clean and visible. Ergonomic designs reduce strain, while clear guarding and safety interlocks prevent accidents. Furthermore, intuitive controls on the glass grinding machine – whether a simple touchscreen interface or clearly labeled manual dials – minimize the learning curve and reduce the potential for errors. Doesn't a safer, more user-friendly workspace contribute directly to higher morale and lower turnover?

Ultimately, the question isn't merely about replacing an old glass grinding machine; it's about strategically upgrading your core fabrication capability. The modern glass edging machine is far more than just a tool; it's the cornerstone of a productive, profitable, and quality-driven glass workshop. It’s a sophisticated glass processing machine designed to elevate every aspect of your operation. Are you ready to move beyond the limitations of outdated technology? Could embracing the latest advancements in glass grinding machine design be the transformative step that propels your workshop into a new tier of efficiency, quality, and competitiveness? The edge you perfect today defines your market position tomorrow. Isn't it time your equipment delivered an edge as sharp as your ambition? Investing in the right glass edging machine isn't just an equipment purchase; it's an investment in the future precision and prosperity of your entire glass fabrication process. Let your next glass processing machine be the powerhouse glass grinding machine that sets new standards in your workshop.