The Soda Ash Market Morning Report:

The main Soda Ash contract 2409 fluctuated and fell yesterday, closing at 2195 yuan/ton, down 38 yuan/ton, or 1.7%. In the spot market, domestic Soda Ash prices remained stable yesterday. Overall, Soda Ash production has decreased, while demand has benefited from the gradual start-up of photovoltaic production lines and high output of float glass, resulting in high growth in Soda Ash consumption overall. Considering that some companies' summer maintenance has been moved forward, Yuanxing's output has increased, the market expects a reduction in maintenance volume, which may exert downward pressure on Soda Ash prices. It is advised to closely track Soda Ash production line maintenance and inventory changes.

The Glass Market Morning Report:

The main Glass contract 2409 fluctuated slightly and rose yesterday, closing at 1682 yuan/ton, up 6 yuan/ton, or 0.36%. In the spot market, the national average price was 1659 yuan/ton, flat from the previous period, with one additional production line under maintenance. In North China, transactions were weak and stable, while in East China, the market was mostly stable. In Central China, production and sales were average, and in South China, transactions were weak due to weather conditions. Overall, glass production remains high, and overall glass inventories at glass manufacturers have shown minor fluctuations; considering the large backwardation in the distant months, it is advised to guard against basis risk.

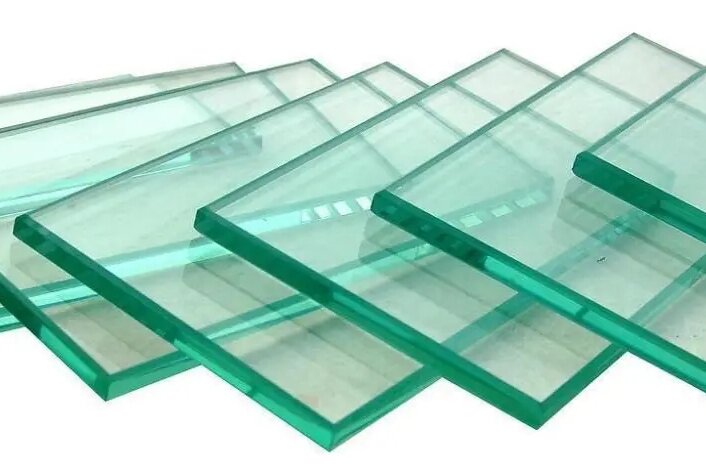

How does a glass edging machine handle different types of glass?

In modern architecture and home decoration, the application of glass is becoming more and more extensive. Whether it is flat glass, curved glass, wire-mesh glass, or painted glass, they all need to be processed meticulously to meet various design requirements. As a key equipment for glass processing, glass edge polishers have a high level of professionalism in handling different types of glass. This article will discuss how glass edging machine handle different types of glass, as well as the technological innovations and applications of Chinese glass edging machine manufacturer(ENKONGS).

I. Classification and Functions of Glass Edging machine

Glass edging machine can be divided into manual edge polishers and automatic edge polishers based on their processing methods. Manual edge polishers are mainly used for grinding the edges of flat glass, and are easy to operate, but have low efficiency. Automatic edge polishers, on the other hand, can automatically complete the grinding, chamfering, and rounding of glass according to set parameters, and are suitable for various types of glass, with high efficiency and high processing accuracy.

The main functions of glass edging machines are as follows:

1. Grinding: Precise grinding of glass edges to make them smooth and even.

2. Chamfering: Forming a certain angle on the edge of glass to improve its safety.

3. Rounding: Making the edge of glass round and smooth to enhance its aesthetics.

4. Grooving: Creating grooves along the edge of the glass to enhance its structural integrity.

II. Technological Innovations for Handling Different Types of Glass by Glass Edging Machines

1. Processing Flat Glass

For the processing of flat glass, glass edging machines utilize advanced linear grinding head designs to ensure stability during the processing. Additionally, high-precision rollers are used to make the glass edges smoother and more even.

2. Processing Curved Glass

For the processing of curved glass, glass polishing machines use adjustable grinding heads that can be adjusted according to the degree of curvature of the glass to ensure processing accuracy. Additionally, an automatic correction system is provided to prevent the glass from shifting during processing.

3. Processing Wire-Mesh Glass

For the processing of wire-mesh glass, the structure of the glass edging machine has been optimized to make the grinding process more stable. Additionally, specialized sanding wheels are used to ensure the aesthetics and safety of the wire-mesh glass edges.

4. Processing Decorative Glass

For the processing of decorative glass, glass edging machines use imported abrasive materials to avoid damaging the decorative patterns on the glass surface. Additionally, a dedicated grinding liquid circulation system is provided to ensure cleanliness during the processing.

III. Technological Innovations and Applications of Chinese Glass Polishing Machine Manufacturers(ENKONGS)

1. Intelligent Control Technology

With the development of artificial intelligence technology, glass edge polishing machine manufacturers in China(ENKONGS) has applied intelligent control technology to glass edging machines, achieving automation and intelligence in equipment. By setting processing parameters, glass edge polishing machines can automatically complete the glass grinding, chamfering, and rounding processing processes, improving production efficiency.

2. Energy-saving and environmental protection technology

Chinese glass edging machine manufacturers(ENKONGS) pays attention to energy conservation and environmental protection, adopting advanced energy-saving technologies to reduce the equipment's energy consumption. At the same time, there is a dedicated grinding liquid circulation system to recycle and treat wastewater, reducing the impact on the environment.

3. High-quality spare parts

Chinese glass edging machine manufacturer(ENKONGS) selects high-quality spare parts to ensure stable operation of the equipment. For example, high-precision rollers and high-quality sanding wheels are used to improve the precision and aesthetics of glass processing.

4. Customized services

To meet the needs of different customers, Chinese glass edge polishing machine manufacturer(ENKONGS) provides customized services. Based on the actual needs of customers, customized glass edge polishing machines are produced to ensure the practicality and high efficiency of the equipment.

In summary, glass edge polishing machines have significant advantages in processing different types of glass. Chinese glass edge polishing machine manufacturers have continuously improved the performance and stability of the equipment through technological innovation, providing strong support for the glass processing industry. In the future, glass edge polishing machines will continue to develop towards automation, intelligence, and environmental protection, helping to promote the prosperity of the glass industry in China.