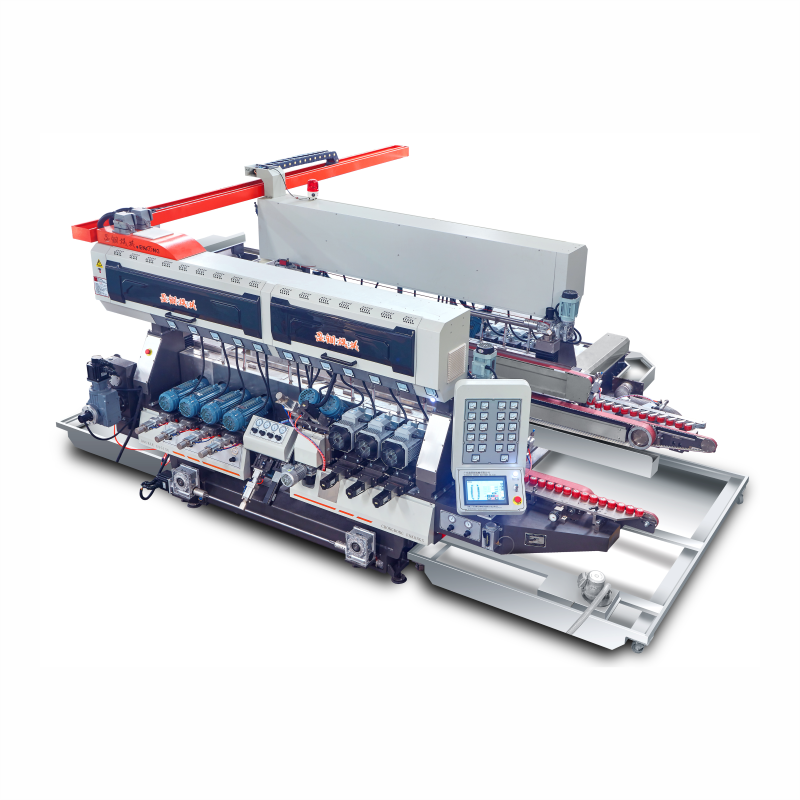

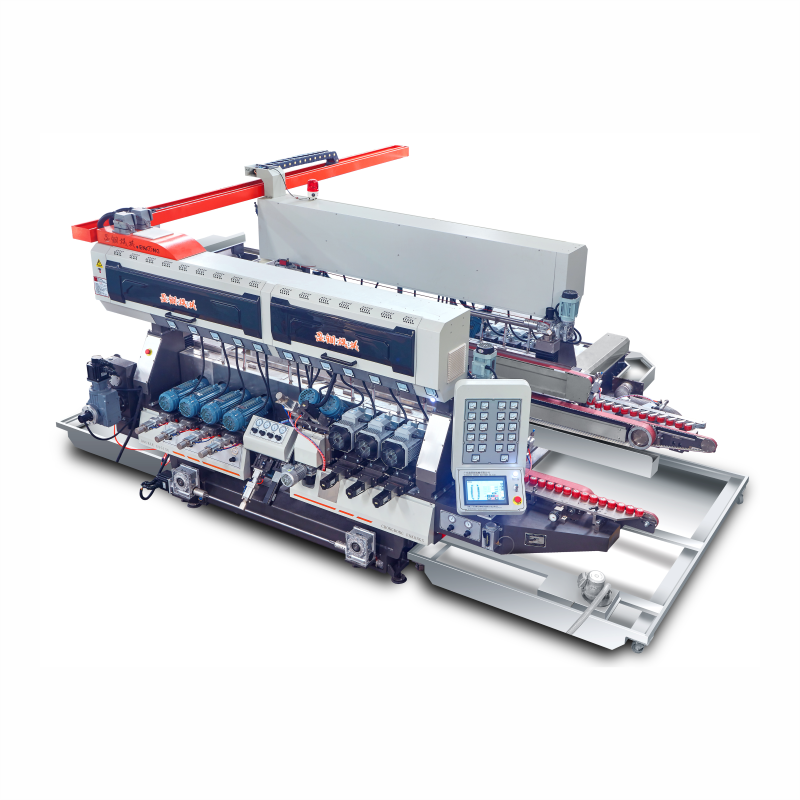

Glass edging machines are essential tools in the glass manufacturing industry, as they play a crucial role in ensuring that glass products have smooth and polished edges. These glass grinding machines use advanced technology and precision engineering to achieve precise results, making them an indispensable asset for glass manufacturers.

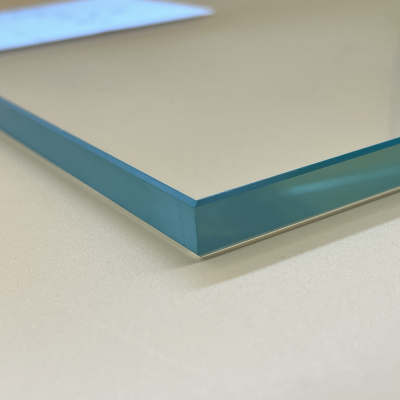

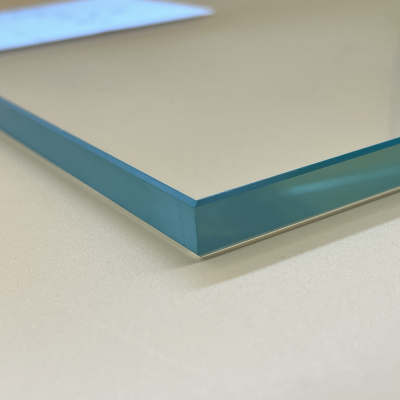

One of the key features of glass edging machines is their ability to grind and polish glass edges to perfection. The process involves using abrasive wheels to remove any rough edges or imperfections on the glass surface, resulting in a smooth and even finish. This is essential for ensuring that glass products are safe to handle and visually appealing to customers.Glass edging machines come in a variety of types and sizes, depending on the specific requirements of the glass manufacturer. Some glass grinding machines are designed for high-volume production, while others are more suitable for smaller-scale operations. Regardless of the size or type of glass grinding machine, they all share the same goal of producing high-quality glass products with smooth edges.

Glass edging machines are essential tools in the glass manufacturing industry, playing a crucial role in ensuring that glass products have smooth and polished edges. These

glass grinding machines use advanced technology and precision engineering to achieve precise results, making them indispensable assets for glass manufacturers. In this article, we will explore the advantages of glass edging machines and how they ensure smooth edges on glass products.

Advantages of Glass Edging Machines:

1. Precision and Accuracy:

Glass edging machines are equipped with advanced computerized controls that ensure precise measurements and consistent results. This level of precision is essential for achieving smooth edges on glass products, as even minor imperfections can affect the overall quality of the finished product.

2. Efficiency and Productivity:

Glass edging machines are designed to be highly efficient, allowing manufacturers to produce glass products quickly and cost-effectively. These

glass grinding machines can handle a wide range of glass thicknesses and sizes, making them suitable for various applications. By automating the grinding and polishing process, glass edging machines help save time and labor costs while increasing productivity.

3. Versatility:

Glass edging machines offer a high degree of versatility, allowing manufacturers to create a wide range of glass products with different shapes and designs. These machines can perform functions such as beveling, chamfering, and drilling, giving manufacturers the flexibility to meet diverse customer requirements.

4. Consistent Quality:

One of the key advantages of glass edging machines is their ability to consistently produce high-quality glass products with smooth edges. By eliminating rough edges and imperfections, these machines ensure that the final product is safe to handle and visually appealing to customers. This level of quality control is essential for maintaining a positive reputation in the industry.

5. User-Friendly Design:

Glass edging machines are designed to be user-friendly and easy to operate, making them accessible to both experienced professionals and newcomers to the glass industry. With intuitive controls and automated features, operators can quickly set up the machine and start production without extensive training or experience.

How Glass Edging Machines Ensure Smooth Edges on Glass Products:

Glass edging machines achieve smooth edges on glass products through a series of precise grinding and polishing processes. These

machines can handle a wide range of glass thicknesses and sizes, making them suitable for various applications. By automating the grinding and polishing process, glass edging machines help save time and labor costs while increasing productivity.

3. Versatility:

Glass edging machines offer a high degree of versatility, allowing manufacturers to create a wide range of glass products with different shapes and designs. These machines can perform functions such as beveling, chamfering, and drilling, giving manufacturers the flexibility to meet diverse customer requirements.

4. Consistent Quality:

One of the key advantages of glass edging machines is their ability to consistently produce high-quality glass products with smooth edges. By eliminating rough edges and imperfections, these machines ensure that the final product is safe to handle and visually appealing to customers. This level of quality control is essential for maintaining a positive reputation in the industry.

5. User-Friendly Design:

Glass edging machines achieve smooth edges on glass products through a series of precise grinding and polishing processes. These

glass grinding machines use abrasive wheels to remove any rough edges or imperfections on the glass surface, resulting in a smooth and even finish. The following steps outline how glass grinding machines ensure smooth edges on glass products:

1. Preparation:

Before the glass is processed, it is important to ensure that the edges are clean and free of any debris or contaminants. This helps prevent scratches or damage to the glass during the edging process.

2. Grinding:

The first step in the edging process involves grinding the edges of the glass to remove any rough or sharp areas. Glass grinding machines use abrasive wheels to grind down the edges, creating a smooth and uniform surface.

3. Polishing:

Once the edges have been ground, the glass is then polished to achieve a smooth and shiny finish. Polishing helps remove any remaining imperfections and enhances the overall appearance of the glass product.

4. Quality Control:

Throughout the edging process, quality control measures are in place to ensure that the finished product meets the highest standards of quality. Operators monitor the glass grinding machine's performance and inspect the glass products to identify any defects or inconsistencies.

5. Final Inspection:

After the edging process is complete, the glass products undergo a final inspection to verify that the edges are smooth and free of any defects. Any necessary touch-ups or adjustments are made to ensure that the finished product meets the customer's specifications.

In conclusion,

glass grinding machines play a critical role in ensuring that glass products have smooth and polished edges. With their precision, efficiency, versatility, consistent quality, and user-friendly design, these glass grinding machines offer a cost-effective and efficient solution for glass manufacturers. By utilizing advanced technology and automation, glass grinding machines help produce high-quality glass products that meet the highest standards of craftsmanship and customer satisfaction.

In conclusion,

In conclusion,