In the realm of glass manufacturing, the precision and quality of the final product are paramount. The journey from raw glass sheets to finished, polished products is a meticulous one, involving several stages of processing. Among these, the role of glass edging machines cannot be overstated. This article delves into the contribution of these machines to product quality control, with a focus on the automatic glass edging machine.

The Significance of Glass Edging Machines

Glass edging machines are designed to shape and finish the edges of glass sheets. They are crucial for achieving the desired shape, size, and smoothness of glass edges, which is essential for both aesthetic appeal and safety. The precision of these machines directly impacts the quality of the final product, making them a cornerstone of glass processing.

Automatic Glass Machines: Efficiency and Precision

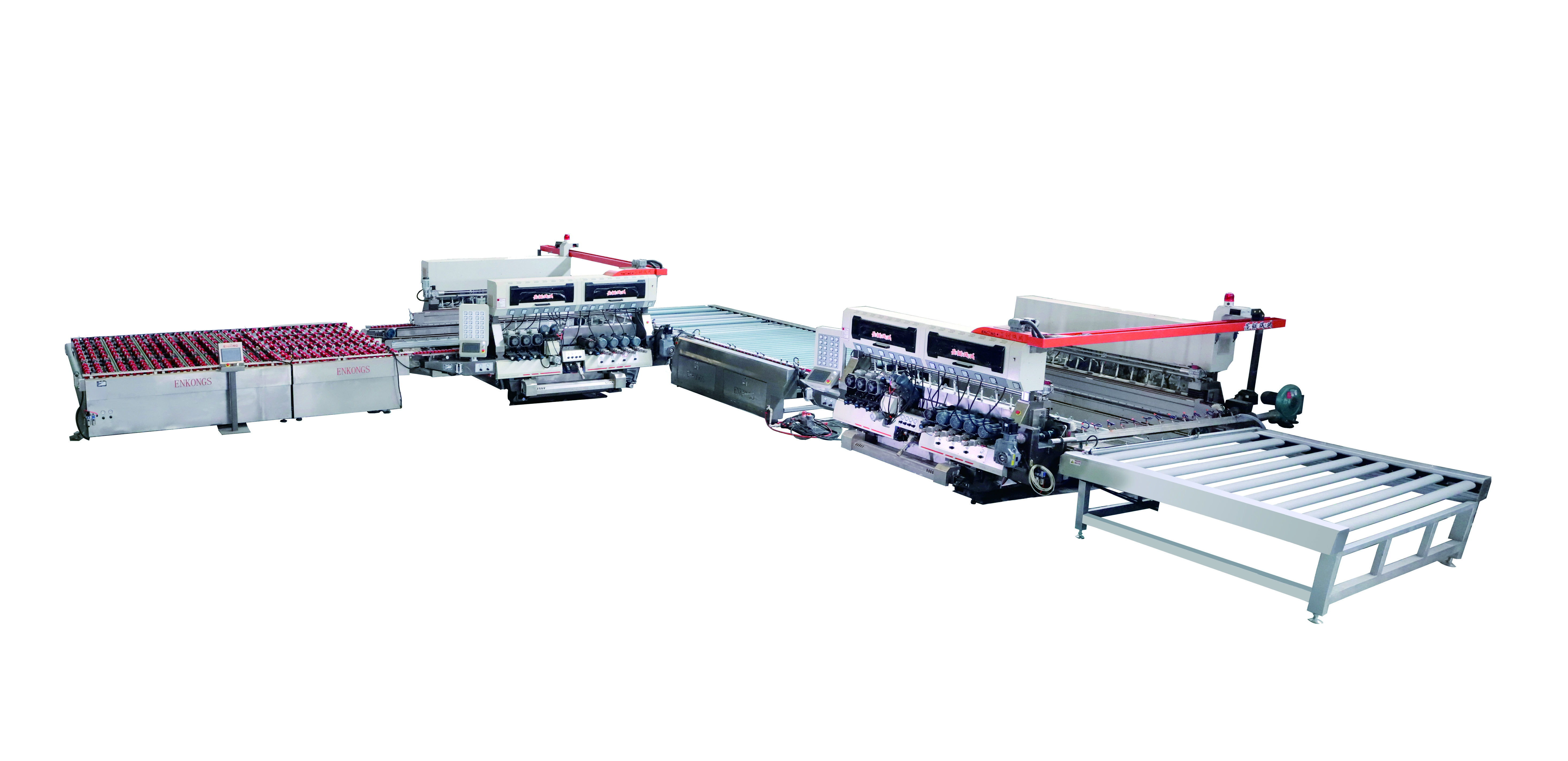

Automatic glass machines represent the pinnacle of glass processing technology. These machines are capable of performing a variety of tasks, from cutting and shaping to edging and finishing, all with a high degree of precision and efficiency. The automation of these processes reduces human error and ensures consistent quality across all products.

The automatic glass machine is equipped with advanced sensors and computerized controls that allow for precise measurements and adjustments. This level of technology ensures that each glass sheet is processed to the exact specifications required, contributing significantly to product quality control.

Glass Grinding Machines: Smoothing the Edges

Glass grinding machines are specifically designed to smooth out the edges of glass sheets. This process is critical for removing any sharp edges that could pose a safety hazard. The grinding machine uses abrasive wheels to gently grind down the edges, creating a smooth, even surface.

The precision of glass grinding machines is vital for achieving the desired finish. A well-ground edge not only enhances the appearance of the glass but also ensures that it is safe to handle and install. This attention to detail is a key factor in maintaining high-quality standards in glass products.

Glass Edging Machines: The Art of Perfection

Glass edging machines are the stars of the show when it comes to giving glass sheets their final shape and finish. These machines come in various types, including straight-line edging machines, beveling machines, and shape edging machines, each designed to create specific edge profiles.

The glass edging machine uses a combination of abrasive wheels and water to cut and shape the glass edges. The precision of the machine ensures that the edges are not only smooth but also perfectly aligned with the desired dimensions. This level of precision is essential for achieving a high-quality finish on glass products.

Glass Equipment: A Comprehensive Approach

Glass equipment encompasses a wide range of machines and tools used in the glass processing industry. From cutting and breaking machines to edging and finishing machines, each piece of equipment plays a vital role in the production process.

The integration of these machines into a comprehensive glass processing line allows for a seamless flow of materials and a consistent level of quality control. The equipment is designed to work together, ensuring that each stage of the process is completed to the highest standards.

Cutting machines are used to accurately cut glass panels to the required dimensions, while drilling machines create holes or cutouts in the glass for specific applications. Washing machines remove any contaminants or residues from the glass surface, ensuring a clean and pristine finish. Tempering ovens are used to strengthen glass panels, making them more durable and resistant to breakage. By utilizing a combination of different glass equipment, manufacturers can streamline the production process, improve efficiency, and maintain high standards of quality control throughout the manufacturing cycle.

Glass Processing Machines: The Future of Glass Manufacturing

Glass processing machines are continuously evolving to meet the demands of the modern glass industry. With advancements in technology, these machines are becoming more efficient, precise, and versatile.

The future of glass manufacturing lies in the ability to produce high-quality products with greater speed and efficiency. Glass processing machines are at the forefront of this evolution, offering new possibilities for innovation and quality control.

Glass edging machines, along with automatic glass machines, glass grinding machines, glass equipment, and glass processing machines, are essential for maintaining product quality control in the glass manufacturing industry. These machines contribute to the precision, efficiency, and consistency of glass processing, ensuring that each product meets the highest standards of quality.

As technology continues to advance, the role of these machines in glass manufacturing will only become more significant. The future holds promise for even greater levels of precision and efficiency, driving the industry towards new heights of quality and innovation.