In the ever-evolving glass manufacturing industry, the demand for precision, efficiency, and scalability has driven innovations in machinery design. Among these advancements, the glass double edging production line stands out as a cornerstone technology, integrating seamlessly with glass production lines and complementing glass deep processing machines to deliver unparalleled results. But what makes this equipment indispensable? How do glass high-speed edging equipment and glass double edging production lines synergize to redefine industrial standards?

1. The Evolution of Glass Production Lines: Where Does the Double Edging System Fit?

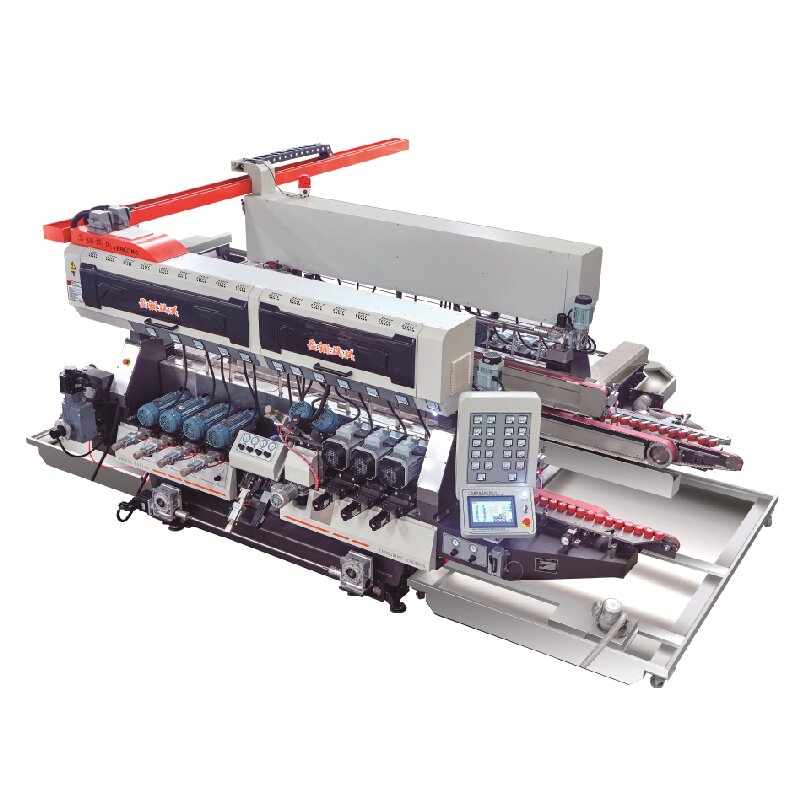

A modern glass production line is a complex ecosystem of interconnected machinery designed to transform raw glass sheets into finished products. At its core, the glass double edging production line serves as a critical component, specializing in simultaneous edge processing for glass panels. Unlike traditional single-edge machines, this system processes both edges of a glass sheet in one pass, significantly boosting throughput.

Key Performance Metrics:

Speed: Integrated glass high-speed edging equipment enables processing speeds of up to 60 meters per minute, reducing cycle times by 40–50%.

Precision: Advanced CNC controls ensure edge tolerances within ±0.1 mm, meeting stringent architectural and automotive standards.

Versatility: Compatible with glass deep processing machines, the system handles glass thicknesses from 3 mm to 25 mm, supporting tempered, laminated, and coated glass.

By automating edge grinding, polishing, and bevelling, the glass double edging production line minimizes human intervention, a feature increasingly demanded in smart glass production lines.

2. Glass Deep Processing Machines: How Do They Enhance Double Edging Systems?

Glass deep processing machines encompass a broad category of equipment, including cutting, drilling, and thermal tempering systems. When paired with a glass double edging production line, they create a seamless workflow. For instance, after edges are refined by glass high-speed edging equipment, the glass may move to a deep processing station for hole drilling or decorative etching.

Synergistic Benefits:

Workflow Integration: The glass production line becomes a unified system, reducing material handling and downtime.

Quality Consistency: Edge uniformity from the glass double edging production line ensures precise alignment in subsequent deep processing stages.

Energy Efficiency: Modern glass deep processing machines and edging systems share energy recovery mechanisms, cutting power consumption by 20–30%.

Industries such as solar panel manufacturing rely on this integration, where edge smoothness (achieved by glass high-speed edging equipment) is critical for structural integrity.

3. Glass High-Speed Edging Equipment: What Sets It Apart?

The heart of the glass double edging production line lies in its glass high-speed edging equipment. Unlike conventional grinders, these systems employ diamond-coated wheels and adaptive pressure control to maintain quality at elevated speeds.

Technical Highlights:

Adaptive Feed Control: Sensors adjust grinding pressure based on glass thickness, preventing chipping.

Multi-Stage Processing: Rough grinding, fine polishing, and edge chamfering occur in a single pass.

Dust Management: Integrated vacuum systems capture 99% of particulate waste, a necessity for cleanroom-compatible glass production lines.

Applications span from smartphone cover glass (requiring mirror finishes) to heavy-duty architectural panels. For example, a glass deep processing machine might follow the edging stage to apply anti-reflective coatings, leveraging the flawless edges produced by glass high-speed edging equipment.

4. Glass Double Edging Production Lines: Who Benefits the Most?

The glass double edging production line is not a one-size-fits-all solution but excels in high-volume, precision-driven sectors.

Primary Industries:

Architectural Glass: Skyscraper facades demand edges resistant to wind loads and thermal stress.

Automotive Manufacturing: Windshields and sunroofs require burr-free edges for safety and aesthetics.

Consumer Electronics: Display glass for devices like tablets relies on ultra-smooth edges from glass high-speed edging equipment.

A case study from a German manufacturer revealed that replacing two single-edge machines with one glass double edging production line reduced floor space usage by 35% and labor costs by 50%. Furthermore, integration with IoT-enabled glass deep processing machines allows real-time quality monitoring, a trend reshaping glass production lines globally.

5. The Future of Glass Production Lines: What’s Next?

As sustainability and automation dominate industry agendas, glass double edging production lines are evolving. Innovations include:

AI-Powered Optimization: Machine learning algorithms predict wheel wear in glass high-speed edging equipment, minimizing downtime.

Hybrid Systems: Combining laser cutting and mechanical edging in a single glass production line.

Circular Economy Integration: Recycling glass dust (collected from glass deep processing machines) into raw materials for construction.

Manufacturers investing in these systems position themselves to lead markets where speed, precision, and eco-efficiency are non-negotiable.

Why Should Manufacturers Prioritize Glass Double Edging Systems?

The glass double edging production line is more than a standalone machine—it’s a catalyst for holistic optimization. By harmonizing with glass high-speed edging equipment and glass deep processing machines, it addresses the core challenges of modern glass production lines: waste reduction, scalability, and adaptability. As industries push toward thinner, stronger, and smarter glass products, adopting this technology isn’t just an option; it’s a strategic imperative.

Whether you’re processing photovoltaic glass or luxury shower enclosures, the question isn’t if but how soon you’ll integrate a glass double edging production line into your operations. The future of glass manufacturing is double-edged—literally and figuratively.