In the demanding world of glass fabrication, the difference between ordinary and extraordinary often lies in the final edge. Achieving that flawless finish, whether for a soaring architectural marvel, a sleek furniture piece, or a precision automotive component, demands more than just skill—it requires the pinnacle of technology: advanced glass processing machinery. At the heart of this finishing revolution lies the indispensable glass edging machine, a cornerstone of modern workshops committed to excellence, efficiency, and safety.

Gone are the days of inconsistent hand-finishing or relying on outdated equipment that compromises quality and throughput. Today’s sophisticated glass grinding machines and dedicated glass edging machines represent a quantum leap forward. They are engineered to deliver unparalleled precision, repeatability, and speed, transforming raw glass sheets into refined, safe, and aesthetically perfect products ready for the market. Investing in the right glass processing machine isn't just an upgrade; it's a strategic decision to future-proof your operation.

The Critical Role of Precision Edging

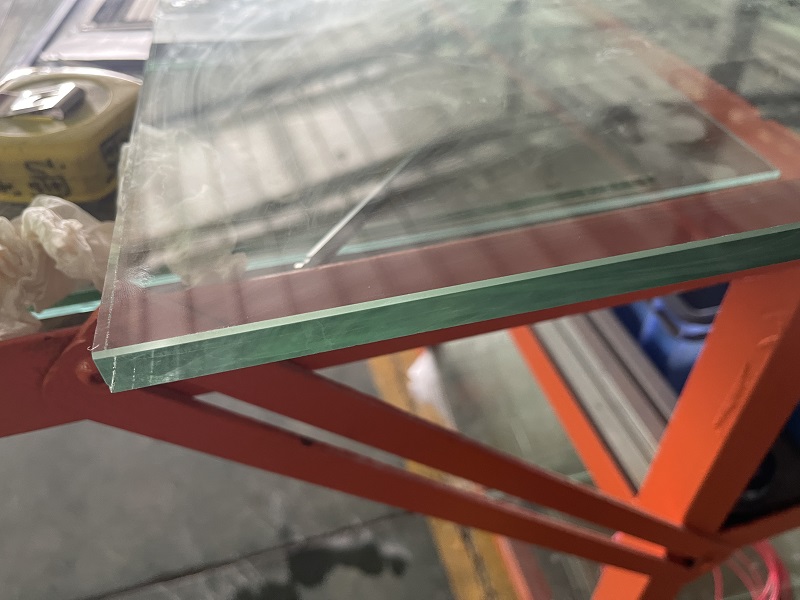

Why is the edge so crucial? Beyond aesthetics, a perfectly finished edge is fundamental for safety, structural integrity, and functionality. Sharp, chipped, or uneven edges are not only unsightly but also hazardous, prone to causing injury or failure. A high-performance glass edging machine systematically eliminates these risks. Through controlled abrasion and polishing, these machines meticulously shape and refine the glass perimeter, creating smooth, consistent bevels, flat polishes, or intricate pencil edges according to exact specifications. This level of precision is simply unattainable consistently with manual methods.

Beyond Edging: The Versatility of Modern Grinding

While dedicated glass edging machines excel at perimeter finishing, the modern glass grinding machine offers remarkable versatility. Many advanced models seamlessly handle both edging and broader surface grinding tasks. Need to calibrate thickness, remove surface imperfections, or prepare glass for further processing like laminating? A robust glass grinding machine is your multi-functional workhorse. This adaptability makes it an incredibly valuable asset, streamlining workflows by reducing the need for multiple specialized units. Integrating such a capable glass processing machine significantly enhances overall shop efficiency.

Unlocking Efficiency and Profitability

Time is money, and nowhere is this truer than in manufacturing. Modern glass processing machinery, particularly automated glass edging machines and glass grinding machines, dramatically accelerate production cycles. Automated loading, programmable settings for different edge profiles, multi-head configurations for simultaneous operations, and consistent high-speed processing mean jobs are completed faster and with less labor intensity. This translates directly to increased throughput, lower per-unit costs, and the ability to take on more complex or higher-volume projects with confidence. The return on investment for a top-tier glass edging machine or versatile glass grinding machine is often realized surprisingly quickly through these efficiency gains.

Ensuring Uncompromising Quality & Consistency

Customer expectations have never been higher. Delivering batch after batch of glass components with identical, flawless edges is non-negotiable. This is where automation in glass processing machines truly shines. Once programmed, a modern glass edging machine replicates the perfect edge profile on every single piece, eliminating human error and variability inherent in manual finishing. Whether it's a simple straight edge or a complex shape, the glass grinding machine executes with robotic precision. This unwavering consistency builds your reputation for quality and reliability, fostering customer trust and loyalty.

Enhancing Workplace Safety

Glass handling and processing carry inherent risks. Traditional grinding and edging methods often involve significant manual contact with abrasive wheels and glass edges. Advanced glass processing machinery is designed with operator safety as a paramount concern. Features like enclosed grinding heads, automated material handling systems, water cooling to suppress dust, emergency stops, and sophisticated guarding minimize direct operator exposure to hazards. Utilizing a well-designed glass edging machine or glass grinding machine significantly reduces the potential for accidents and creates a safer, more compliant work environment.

Applications Spanning Industries

The impact of these machines is felt across countless sectors:

Architectural & Construction: Creating safe, beautiful edges for windows, doors, shower enclosures, partitions, railings, and staircases. A reliable glass edging machine is essential for meeting building codes and aesthetic demands.

Furniture & Interior Design: Producing polished edges for tabletops, shelves, display cases, and decorative panels. Precision from a glass grinding machine elevates the luxury feel.

Automotive & Transportation: Manufacturing mirrors, windshields (after cutting), sidelites, and interior components requiring exacting edge specifications. Consistency from the glass processing machine is critical.

Appliances & Electronics: Finishing glass for oven doors, refrigerator shelves, touchscreens, and display covers. A high-quality glass edging machine ensures safety and durability.

Solar Energy: Preparing glass substrates and covers for photovoltaic panels, where edge integrity affects longevity and performance.

Choosing the Right Glass Processing Partner

Selecting the optimal glass grinding machine or glass edging machine requires careful consideration. Evaluate the range of edge profiles you need (straight, bevel, pencil, ogee), the typical glass thicknesses and sizes you handle, desired levels of automation (manual, semi-automatic, CNC), required throughput, and available workshop space. Look for reputable manufacturers known for robust construction, reliability, ease of maintenance, intuitive controls, and excellent technical support. The ideal glass processing machine is an investment that grows with your business.

Future-Proofing Your Glass Fabrication

The technology behind glass processing machinery continues to evolve. Innovations in diamond abrasives, spindle technology, control systems (including AI integration for predictive maintenance and optimization), and energy efficiency are constantly emerging. Partnering with a forward-thinking supplier ensures you have access to these advancements. Investing in a modern, adaptable glass edging machine or a multi-functional glass grinding machine positions your business at the forefront of the industry, ready to meet future challenges and opportunities.

Embrace the Edge of Innovation

In a competitive landscape, superior finishing is a powerful differentiator. Elevating your glass edges from functional to exceptional is no longer a luxury; it's a necessity driven by quality demands, safety standards, and economic pressures. By integrating advanced glass grinding machines and precision-engineered glass edging machines into your workflow, you unlock new levels of capability. These sophisticated glass processing machines empower you to work faster, safer, smarter, and with breathtaking consistency. They transform raw potential into polished perfection, enabling you to deliver glass products that truly shine, project after project. Discover the transformative power of modern edge technology and redefine what’s possible in your glass workshop.