Breaking Through: Embracing New-Era Glass Processing Technology: The Value Reimagination of Edge Polishing Machines

Glass craftsmanship has a long history, and its production and design reflect human creativity and the evolution of technology. In the modern home and architectural design industry, the use of glass is becoming increasingly widespread, and among them, the glass edge grinder has become an indispensable processing tool. Today, we introduce you to an efficient, intelligent, and energy-saving glass edge grinder that will fundamentally change your traditional perception of glass processing.

In the modern glass processing industry, there is an increasing demand for high-quality glass products. Among them, how to handle glass materials more efficiently and accurately has become a focus of the industry. As an important equipment in modern glass processing, glass edge grinding machine has emerged with its unique advantages. This article will give you a detailed introduction to the features, advantages, and important applications of glass edge grinding machine in the processing process.

One: Breaking the Ice - Understanding Glass Edge Polishing Machines

**Product Definition**

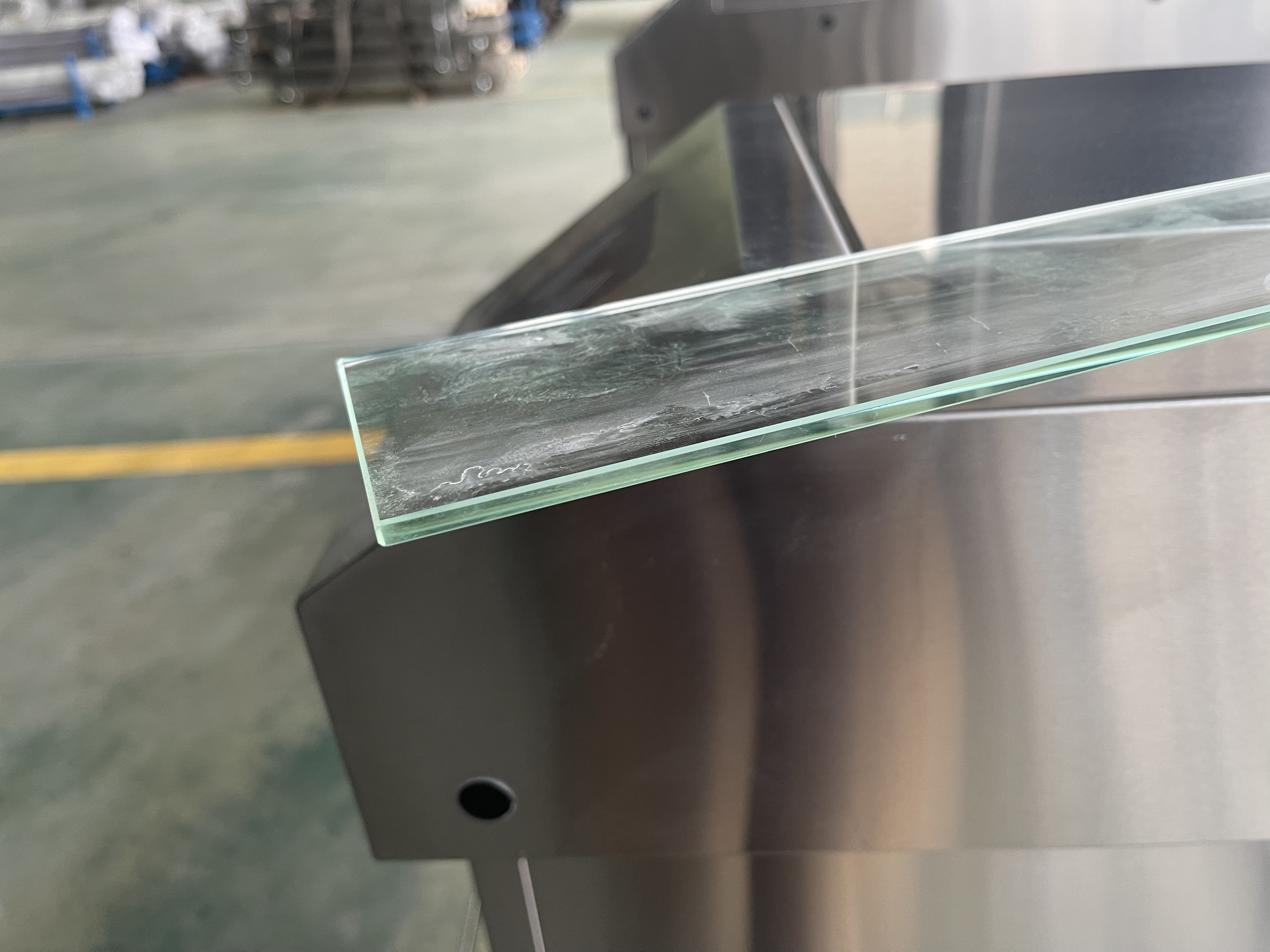

The glass edge polishing machine is a specialized processing equipment for various sizes, shapes, and edge requirements. It can effectively polish and refine the edges of glass, improving product quality and efficiency. Especially when faced with complex shapes such as curves or curved glass, this glass edge grinding machine can handle them easily.

Technological Innovation

Traditional glass processing methods are not only inefficient, but also often have difficulties in processing special-shaped glass. However, our edge grinder adopts advanced CNC technology, enabling precise processing of complex shapes. Whether you need straight or curved edges, it can easily handle them.

Two, Why Choose Our Glass Edge Grinding Machine?

**High-efficiency production capacity**

Firstly, this glass edge grinder can greatly improve your production efficiency. Compared with traditional manual operation and mechanical cutting, its fast and accurate automated working method significantly improves processing speed, making your production line run more smoothly. At the same time, this glass edge grinding machine also has an intelligent threading function, which can effectively reduce waiting time in the production process.

**Reduce Energy Consumption and Promote Environmental Protection**

Secondly, our glass edge grinding machines are equipped with advanced energy-saving technology, which can significantly reduce energy consumption. During long-term operation, its energy consumption is significantly lower than that of traditional equipment, not only saving your electricity bills but also benefiting environmental protection. In addition, our products are equipped with advanced cooling systems, effectively extending the service life of the glass edge grinding machines.

**Precision craftsmanship and high quality**

Furthermore, with precise control systems and high-quality cutting tools, our edge polishing machines can ensure a smooth and precise edge on every piece of glass, whether it has a straight or curved edge. This meets your high standards and not only improves the appearance quality of the product but also enhances its durability and practicality.

**Flexible Adaptation and Intelligent Connectivity**

Our edge polishing machines are able to adapt flexibly and quickly adjust their working modes when faced with different sizes and shapes of glass. At the same time, they support intelligent connection with other equipment, enabling instant information sharing and synchronized work, making the entire production process more efficient and smooth.

Three. Notable Effects in Real-World Applications

In practical use, this glass edge grinder performs particularly well when faced with curved or bent glass. Its powerful functions and precise control system ensure that even complex curved edges can be perfectly processed. Additionally, its high efficiency and low energy consumption significantly reduce production costs and energy consumption. Meanwhile, the intelligent connectivity function makes the entire production process smoother and more efficient. Whether from the quality of the product, production efficiency, or cost considerations, our glass edge grinder is an invaluable choice for you.

4. Conclusion

In this era of pursuing efficiency, environmental protection, and intelligence, our glass edge polishing machine is the ideal choice you need. It not only improves production efficiency and quality, but also reduces energy consumption and production costs. Whether you are a home appliance manufacturer or a building designer, we believe that this product will bring you unprecedented value and experience. Join us now! Start your efficient glass processing journey!

With the continuous advancement of technology and the increasing automation of the industrial sector, glass edge polishing machines have become an essential piece of equipment in modern glass processing. Their high efficiency, precision, flexibility, and intelligent connectivity features have brought about revolutionary changes to glass processing enterprises. If you want to improve production efficiency, reduce energy consumption, shorten production cycles, and achieve operational convenience, consider introducing a high-efficiency glass edge polishing machine. It will bring you unexpected benefits for your business.