The Silent Profit Drain in Your Workshop

The glass fabrication industry is booming, with demand for custom architectural panels, automotive windows, and luxury interiors rising by 18% annually. Yet, many workshops are hemorrhaging profits due to outdated glass processing machines. A 2024 study found that companies relying on standalone, non-integrated systems waste 32% more material and 25% more labor hours than those using modern multi-functional setups. If your margins are shrinking despite increasing orders, your glass edging machine might be the culprit. Let’s uncover why traditional systems fail and how to future-proof your workflow.

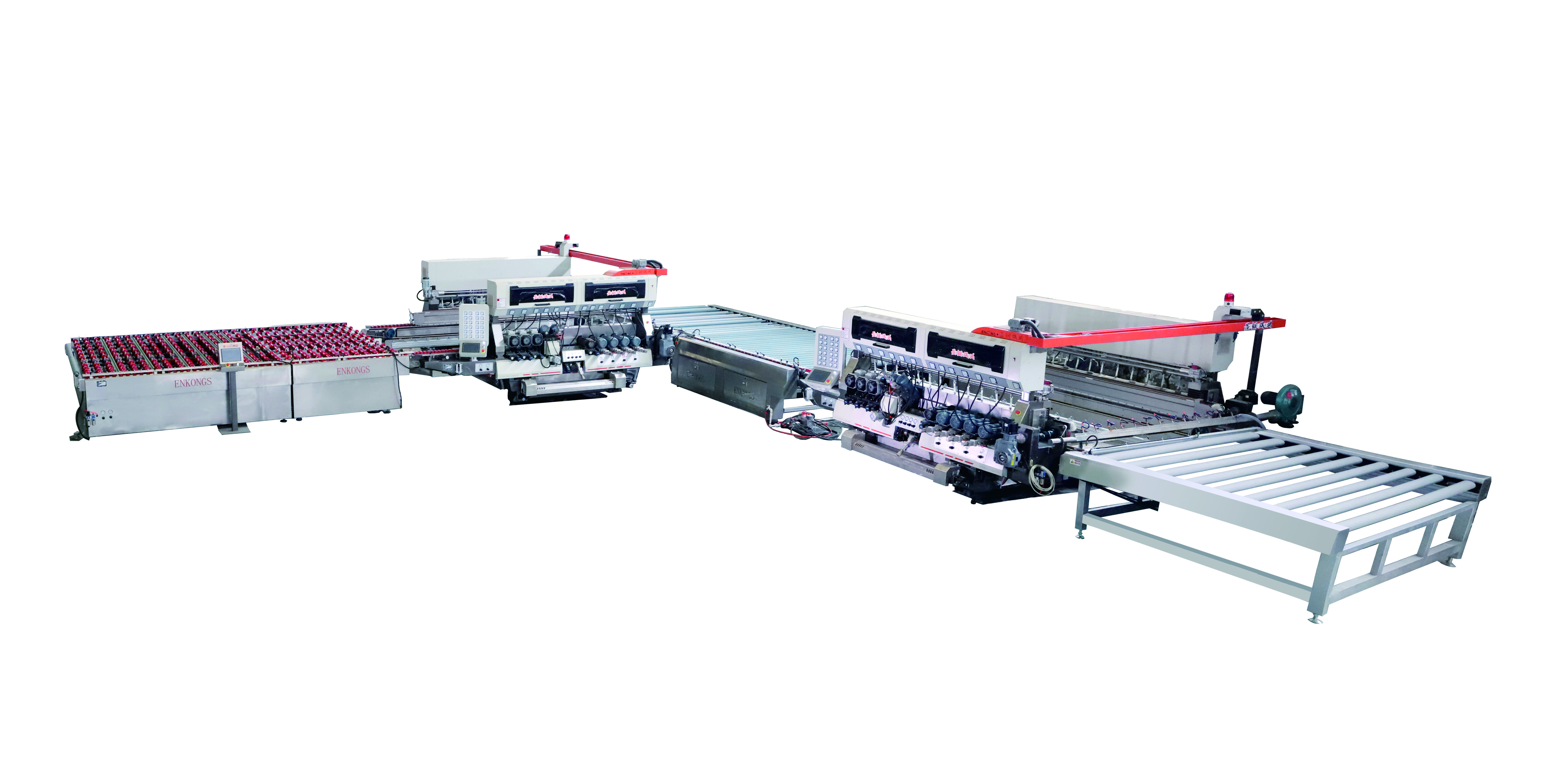

1. The Standalone Trap: Glass Edging Machinevs. All-in-One Processing Systems

Many workshops still use a fragmented approach: a glass edging machine for beveling, a separate cutter for shaping, and a glass polishing machine for finishing. This "island" workflow creates bottlenecks, especially for complex projects like curved stair railings or anti-glare facades.

The Hidden Costs of Disconnected Systems:

Material Waste: Manual transfers between machines increase handling errors. For example, glass cracked during transfer from a glass processing machine to a glass edging machine costs

150

150–500 per sheet.

Labor Inefficiency: Operators spend 30% of their time adjusting clamps and recalibrating tools instead of producing.

Quality Gaps: Inconsistent alignment between machines leads to uneven edges, forcing your glass polishing machine to overcompensate.

Why All-in-One Systems Win:

Modern glass edging machines combine cutting, drilling, edging, and even pre-polishing in a single automated unit. The Gloss Master X7, for instance, reduces edging time for a 10mm tempered glass panel from 45 minutes to 12 by eliminating manual transfers.

2. Precision Matters: Why Glass Polishing Machines Fail Without Accurate Cutting

A glass polishing machine can only shine what it’s given. If your glass processing machine delivers jagged edges or micro-fractures, polishing becomes a game of diminishing returns.

The Domino Effect of Poor Processing:

Energy Waste: A glass polishing machine working on rough edges consumes 40% more power due to prolonged buffering.

Tool Wear: Abrasive pads on polishing machines degrade 2x faster when correcting errors from upstream processes.

Client Dissatisfaction: Even minor imperfections in edging (caused by an outdated glass processing machine) become glaring under a high-gloss polish.

Integrated Precision:

Advanced glass edging machines use laser-guided CNC systems to achieve edge smoothness within 0.05mm variance. This allows your glass polishing machine to focus on enhancing clarity, not fixing flaws—slashing polishing time by 50%.

3. 5 Upgrades Your Glass Processing Machine Needs in 2024

To stay competitive, your glass processing machine must adopt these innovations:

a) AI-Powered Optimization

AI algorithms analyze glass thickness, curvature, and stress points to auto-adjust cutting and edging parameters. For example, Smart Cut AI reduces material waste by 22% by optimizing sheet layouts.

b) Hybrid Edging/Polishing Heads

Some glass processing machines now include interchangeable tools, like diamond grinding heads for edging and felt pads for pre-polishing. This hybrid approach cuts downtime between processes.

c) Energy Recovery Systems

Modern machines recycle 30% of energy used during cutting/edging cycles. Pair this with a variable-speed glass polishing machine to reduce your workshop’s carbon footprint (and utility bills).

d) IoT-Enabled Predictive Maintenance

Sensors in your glass edging machine monitor motor health, belt tension, and coolant levels, sending alerts before breakdowns occur. One manufacturer reported a 70% drop in unplanned downtime after adopting IoT.

e) Multi-Axis Flexibility

3D curved glass requires machines with 7-axis mobility. Upgraded glass processing machines can edge radii as tight as 20mm, unlocking markets like aerospace and high-end automotive.

Case Study: Reviving Profits with a Modern Glass Processing Machine

Vertex Glass Co. replaced their 2018 standalone glass processing machine and glass edging machine with an all-in-one system. Results in 6 months:

55% faster order fulfillment (12→5 days for 100 custom shower doors)

18% lower material waste due to AI-optimized cutting

90% fewer returns thanks to seamless integration with their glass polishing machine

Conclusion: From Cost Center to Profit Engine

A next-gen glass processing machine isn’t just about speed—it’s about creating a unified ecosystem where cutting, edging, and polishing work in harmony. By eliminating manual handoffs, maximizing precision, and slashing energy costs, you can transform your workshop into a high-margin powerhouse.