Glass single-sided machine is a special equipment used to handle single edges of glass in the field of glass deep processing. It is mainly used for straight edge grinding of architectural glass, home decoration glass and craft glass. Glass single-sided machine supports 45° chamfering treatment and can process glass with a thickness of 1-20mm.

Core functions:Glass single-sided machine is mainly used for coarse grinding, fine grinding and polishing of single-sided straight edges of glass. Some models support 45° chumfering, which is suitable for doors and windows, architectural glass and other scenes

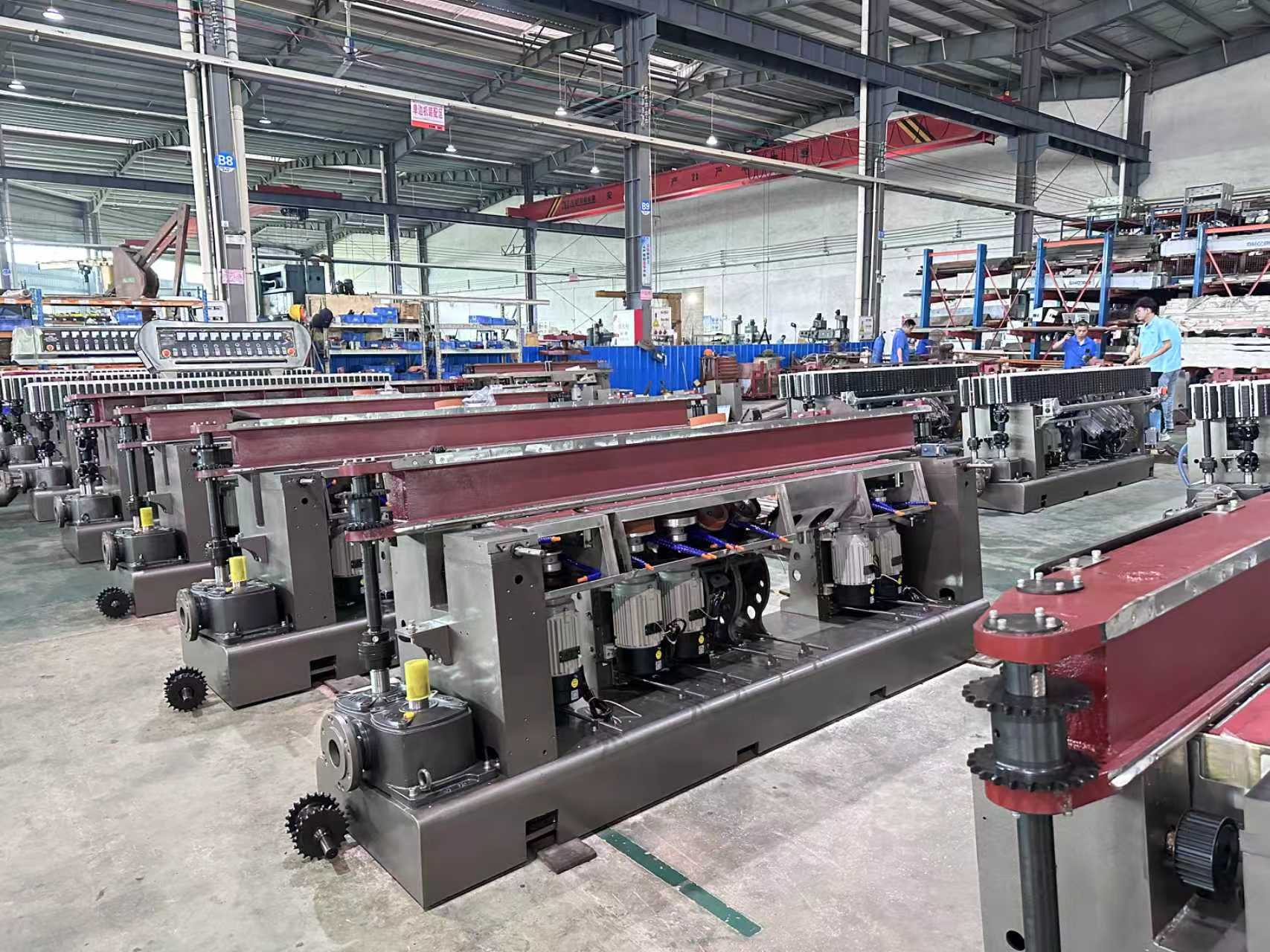

Structural characteristics:

1.Cast iron cast base and bracket are used to ensure the stability of long-term use.

2.The transmission system supports variable speed adjustment of 0-4m/minute

3.Equipped with a circulating water cooling system to reduce the temperature of the grinding wheel 12

Applicable scenarios.

It is suitable for the processing of small and medium-sized glass products, such as door and window glass, architectural curtain wall glass and other scenes that require unilateral processing.

The glass is ground by high-speed motors and grinding wheels to achieve the flatness and smoothness of the glass edges.

Variable speed adjustment: a wide range of speed adjustment meets the processing needs of different manufacturers and improves processing efficiency.

Stable clamping: The clamping system ensures the stable clamping of ultra-thin glass and other difficult-to-clamping materials to avoid damage during processing.

Accuracy and stability: The overall design ensures the stability and continuity of grinding accuracy and meets the requirements of high-precision processing.

Easy to operate: The organic cooperation between the control part and the working part makes the operation simple and easy to use.

Whole-process monitoring: The whole process of monitoring the work process through transparent observation holes ensures the safety and controllability of the processing process.

Glass polishing machines are used to smooth and finish the edges of glass panels, removing roughness and achieving a uniform finish. The price range and specifications vary depending on the model and capacity

Glass edger:

Function: Cutting, sanding, polishing and other finishing on the edges of the glass to form smooth or shaped corners

Application scenario: production process of flat glass, glassware, wine bottles and other products

Related equipment: glass single-side machine, glass blowing machine

In the architectural glass and decorative glass industry, edge processing directly affects safety and aesthetics, and needs to be standardized through edger equipment.