In the realm of glass processing, precision, efficiency, and versatility are paramount. Among the array of specialized equipment that defines modern glass manufacturing, the glass processing machine stands out as a cornerstone of mass production and high-precision processing. As a critical subset of glass edging machines—which themselves are integral to the broader category of glass processing machines—this equipment is engineered to refine the edges of flat glass panels with unparalleled accuracy, particularly for creating straight, polished edges on both sides of a glass sheet simultaneously. Its role extends beyond mere functionality; glass edging machine ensures safety by eliminating sharp edges, enhances aesthetic appeal through smooth finishes, and enables seamless integration of glass into architectural, automotive, and decorative applications.

This article delves into the design, functionality, types, operational mechanisms, applications, and technological advancements of the glass double straight line edging machine. By exploring its place within the ecosystem of glass grinding machines and other glass processing tools, we aim to provide a thorough understanding of its significance in modern manufacturing.

1. Defining the Glass Double Straight Line Edging Machine

A glass edging machine is a specialized glass edging machine designed to process two parallel edges of a glass sheet in a single pass. Unlike single-sided edgers, which handle one edge at a time, or multi-functional machines that tackle curved or irregular edges, this equipment focuses exclusively on straight edges, delivering consistent results across large volumes of glass.

At its core, the machine combines the principles of glass grinding machines—which use abrasive tools to remove material—and polishing systems to achieve a smooth, transparent finish. What distinguishes it is its dual-edge processing capability, which streamlines production by reducing handling time and ensuring symmetry between parallel edges. This makes it indispensable in industries where uniformity is critical, such as in the production of window panes, glass doors, mirrors, and automotive glass.

2. Role in the Glass Processing Ecosystem

To appreciate the value of the glass double straight line edging machine, it is essential to contextualize it within the broader landscape of glass processing machines. Glass processing encompasses a range of operations, including cutting, grinding, edging, polishing, tempering, and laminating, each performed by specialized equipment.

•Glass cutting machines initiate the process by shaping raw glass sheets into desired dimensions.

•Glass grinding machines then refine surfaces or edges by removing excess material, correcting imperfections, or preparing surfaces for further treatment.

•Glass edging machines, a subset of grinding equipment, focus specifically on edge refinement, addressing safety (by eliminating sharpness) and aesthetics (by creating uniform profiles).

The glass processing machine fits within this chain as a post-cutting, pre-finishing tool. After a glass processing machine is cut to size, this machine processes its two parallel edges, ensuring they are straight, smooth, and ready for assembly or additional treatments like tempering or coating. Its efficiency in handling dual edges simultaneously reduces production bottlenecks, making it a staple in high-volume manufacturing lines.

3. Core Components and Design

A glass double straight line edging machine is a complex assembly of mechanical, electrical, and pneumatic systems, each contributing to its precision and reliability. Key components include:

3.1 Frame and Bed

The frame serves as the machine’s foundation, providing structural stability to withstand the vibrations and forces generated during grinding. Typically constructed from high-grade steel or cast iron, glass edging machine minimizes deflection, ensuring that the glass remains aligned with the grinding tools throughout the process. The bed, a flat, rigid surface atop the frame, supports the glass as it moves through the machine, often featuring guide rails to maintain straight-line movement.

3.2 Grinding and Polishing Units

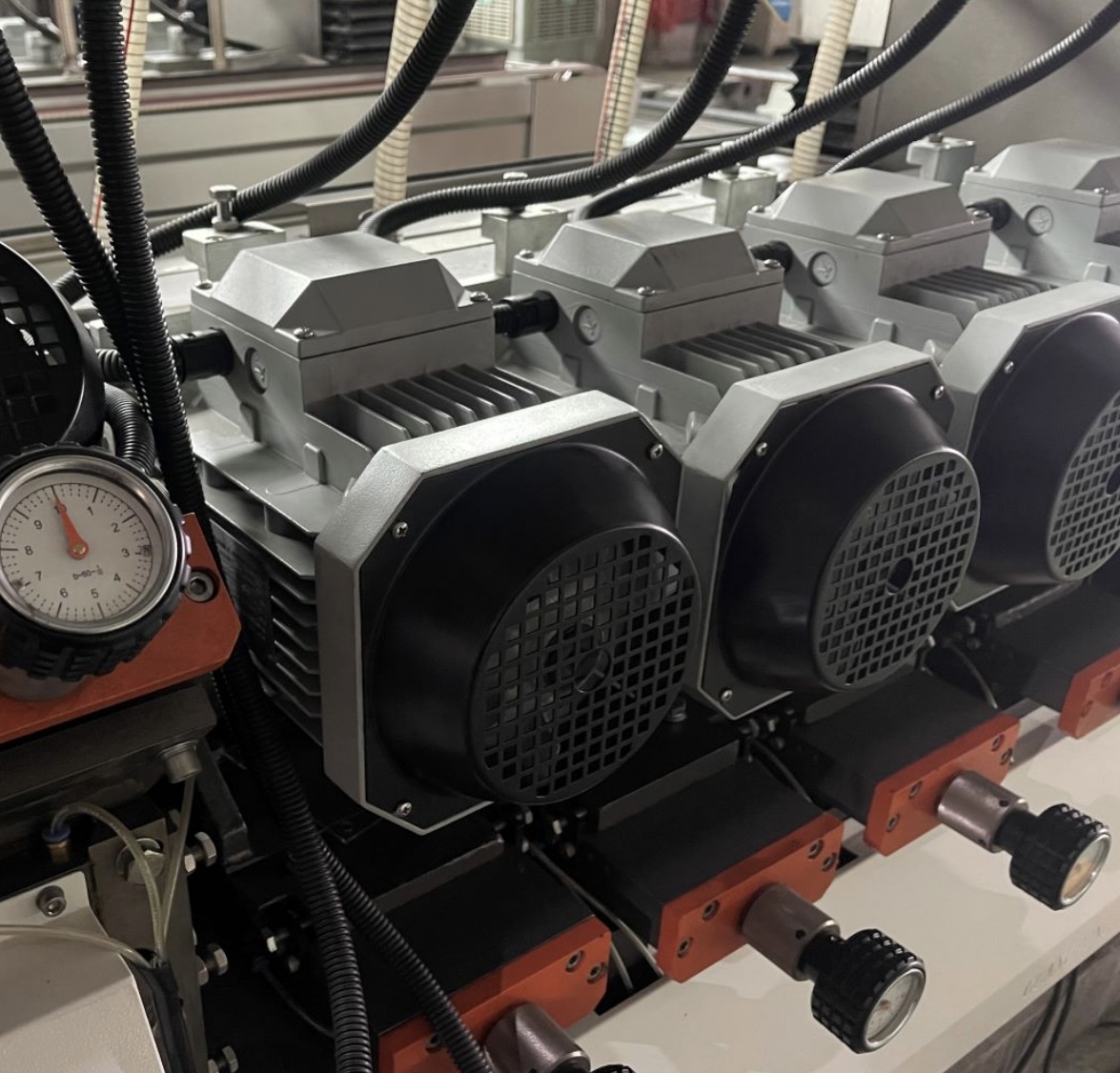

The heart of the machine lies in its grinding and polishing units, which consist of multiple spindles fitted with abrasive wheels. These units are positioned on both sides of the glass path to process the two parallel edges simultaneously.

•Grinding wheels: Made from materials like silicon carbide, aluminum oxide, or diamond, these wheels vary in grit size to accommodate different stages of processing. Coarse grits (e.g., 80–120) remove excess material and shape the edge, while medium grits (e.g., 240–400) refine the surface.

•Polishing wheels: Usually composed of felt, cork, or resin-bonded abrasives, these wheels deliver the final smooth, transparent finish. Fine grits (e.g., 600–1200) or polishing compounds may be used to achieve a mirror-like edge.

The number of spindles varies by machine model, with high-end units featuring 6–10 spindles to enable progressive grinding and polishing in a single pass.

3.3 Conveying System

To ensure consistent movement of the glass through the machine, a robust conveying system is employed. This typically includes rubberized rollers or belts that grip the glass gently but firmly, preventing slippage while avoiding scratches on the glass surface. The speed of the conveyor is adjustable, allowing operators to match it to the glass thickness, edge profile, and desired finish—critical for maintaining precision across different materials (e.g., float glass, tempered glass, or low-iron glass).