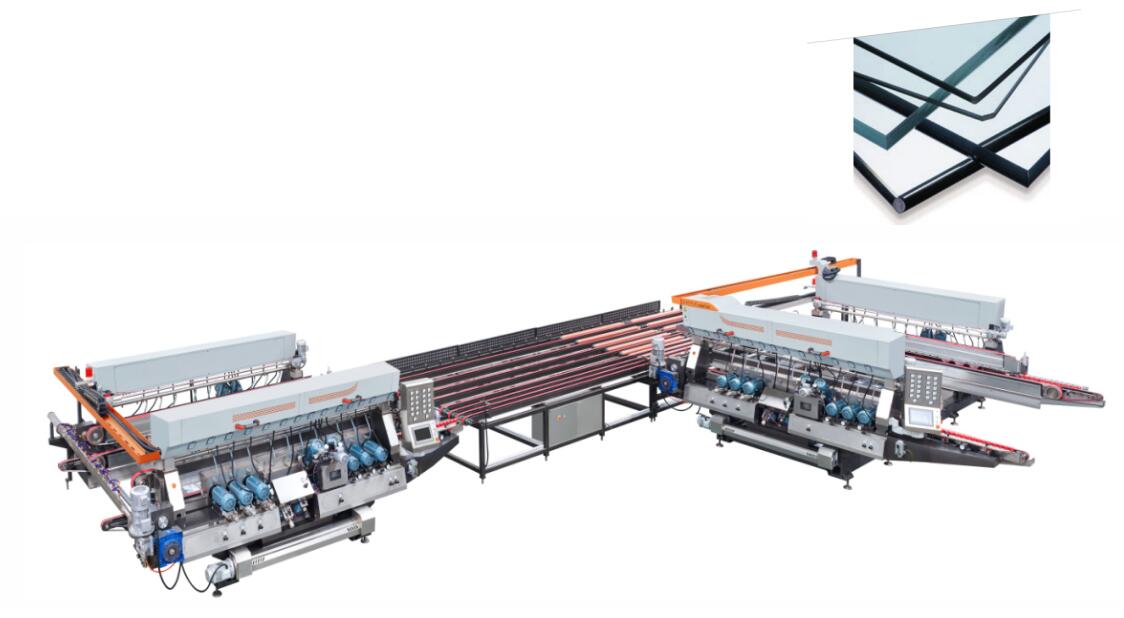

Glass polishing machines are essential tools in the manufacturing industry, particularly in the production of glass products. These glass polishers utilize various polishing techniques to achieve a smooth and shiny finish on glass surfaces. In this article, we will explore the different polishing techniques used in glass polishing machines and highlight the importance of these machines in the manufacturing process.

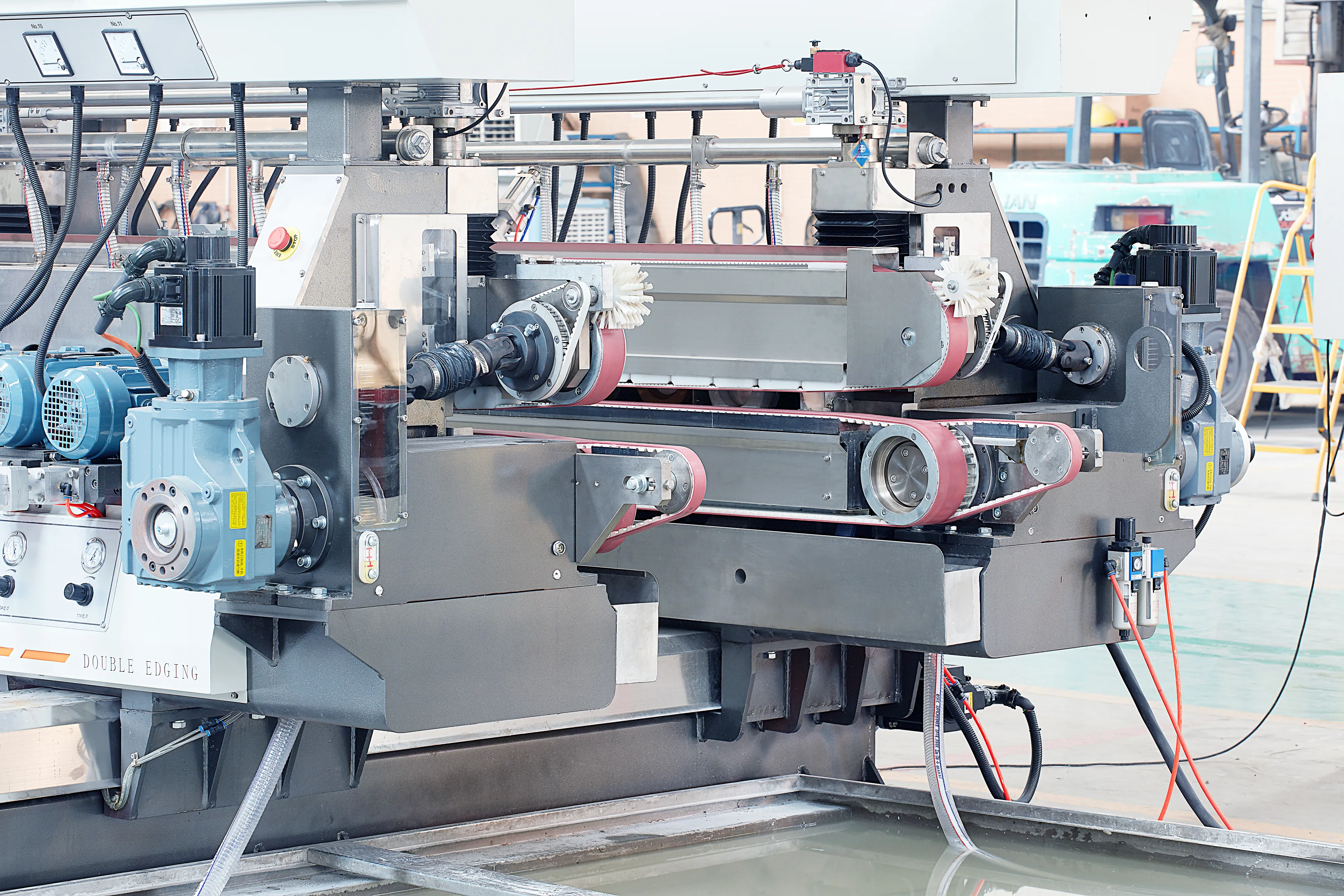

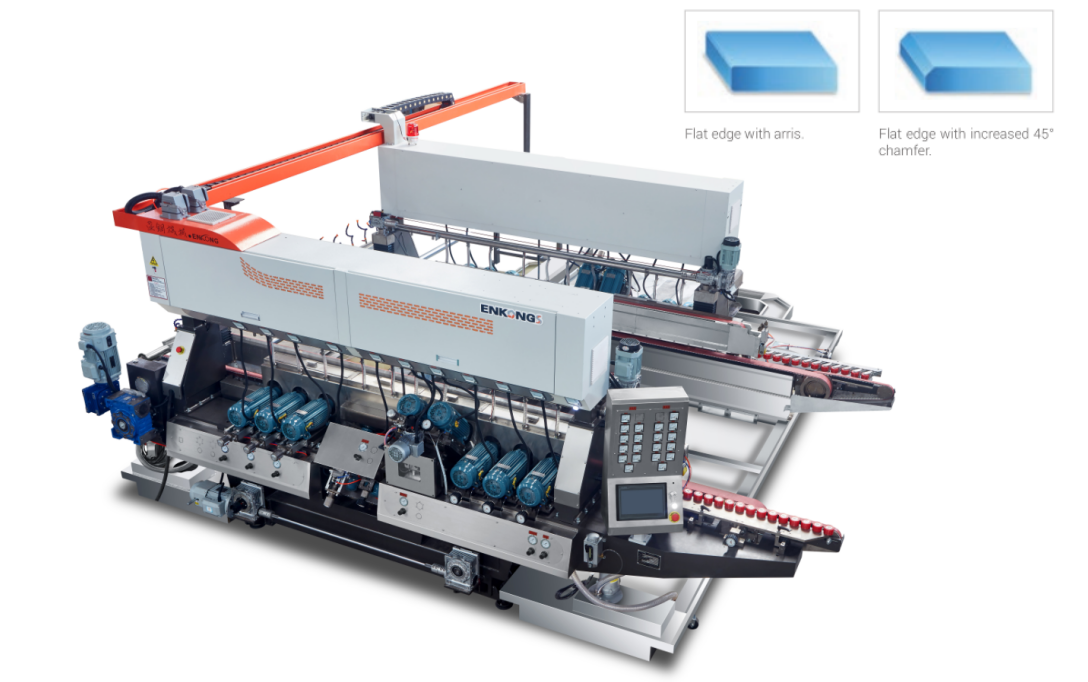

One of the most common polishing techniques used in glass polishing machines is mechanical polishing. This technique involves the use of abrasive materials, such as sandpaper or diamond pads, to remove imperfections from the surface of the glass. Mechanical polishing is effective at eliminating scratches and other surface defects, resulting in a polished and flawless finish. Glass polishers equipped with mechanical polishing capabilities are widely used in industries that require high-quality glass products, such as the automotive and electronics industries.

Chemical polishing is another popular technique used in glass polishers. This technique involves the use of a chemical solution to dissolve the surface of the glass, resulting in a smooth and shiny finish. Chemical polishing is particularly effective for glass products with complex shapes or delicate surfaces, as it can be challenging to achieve a uniform finish with mechanical polishing alone. Glass polishing machines that incorporate chemical polishing capabilities are in high demand in industries that require precise and consistent polishing results, such as the pharmaceutical and optical industries.

Electrochemical polishing is a specialized technique used in glass polishers to remove surface imperfections from glass surfaces. This technique utilizes an electric current to dissolve the surface of the glass, resulting in a smooth and polished finish. Electrochemical polishing is often preferred for glass products with intricate designs or tight tolerances, as it offers a high level of precision and control over the polishing process. Glass polishing machines equipped with electrochemical polishing capabilities are essential in industries that require fine detail and accuracy in their glass products, such as the aerospace and medical industries.

Ultrasonic polishing is another advanced technique used in glass polishers. This technique utilizes high-frequency vibrations to remove small scratches and imperfections from glass surfaces, resulting in a smooth and glossy finish. Ultrasonic polishing is particularly effective for glass products with delicate surfaces or complex shapes, as it provides a gentle and precise polishing action. Glass polishers that incorporate ultrasonic polishing capabilities are highly sought after in industries that demand superior surface finish and quality, such as the luxury goods and jewelry industries.

In addition to these techniques, there are also specialized polishing techniques used in glass polishers, such as laser polishing technology. This cutting-edge technique utilizes laser beams to remove surface imperfections from glass surfaces with exceptional precision and efficiency. Glass polishing machines equipped with laser polishing capabilities are at the forefront of technological innovation in the glass manufacturing industry, offering unparalleled levels of accuracy and consistency in the polishing process.

Overall, glass polishing machines play a crucial role in the production of high-quality glass products, and the different polishing techniques they employ are essential for achieving the desired finish. Whether using mechanical, chemical, electrochemical, ultrasonic, or laser polishing techniques, these glass polishers are instrumental in ensuring that glass products meet the highest standards of quality and aesthetics. Manufacturers across various industries rely on glass polishing machines to deliver polished and flawless glass products that meet the demands of their customers.

In conclusion, glass polishers are indispensable tools in the manufacturing industry, and the different polishing techniques they utilize are vital for achieving superior surface finish and quality in glass products. As technology continues to advance, these glass polishers will continue to evolve and incorporate new and innovative polishing techniques to meet the ever-changing demands of the market. With their ability to deliver precise and consistent polishing results, glass polishing machines are poised to remain essential assets in the production of high-quality glass products for years to come.