【Custom model, price is for reference only】

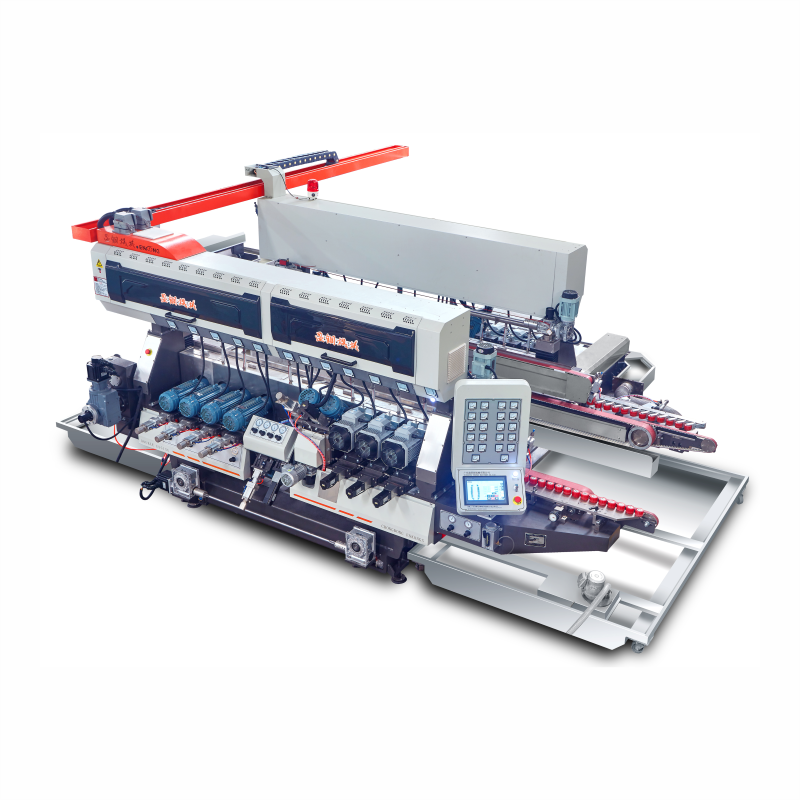

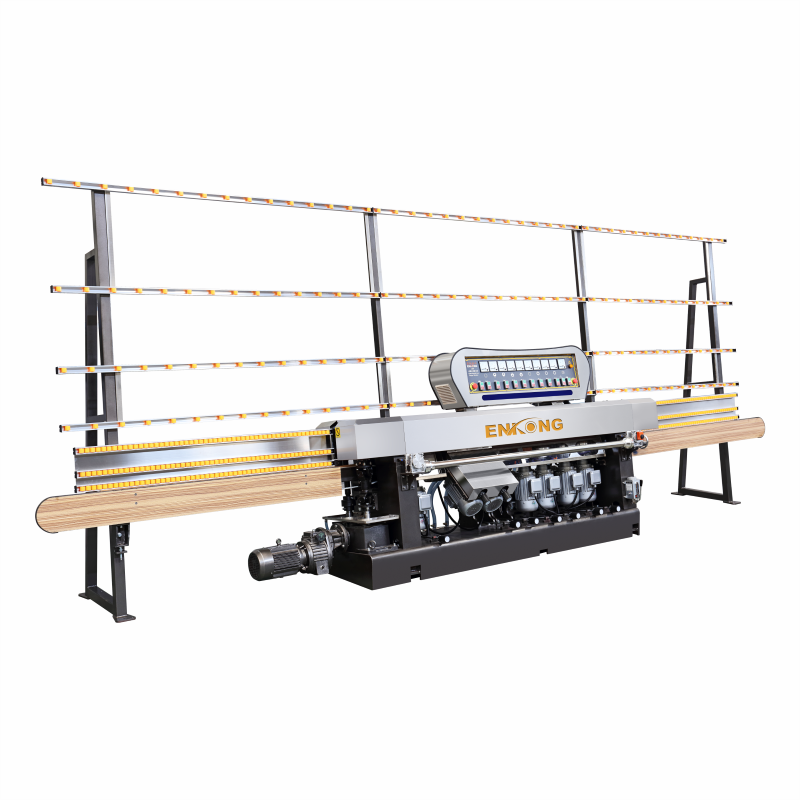

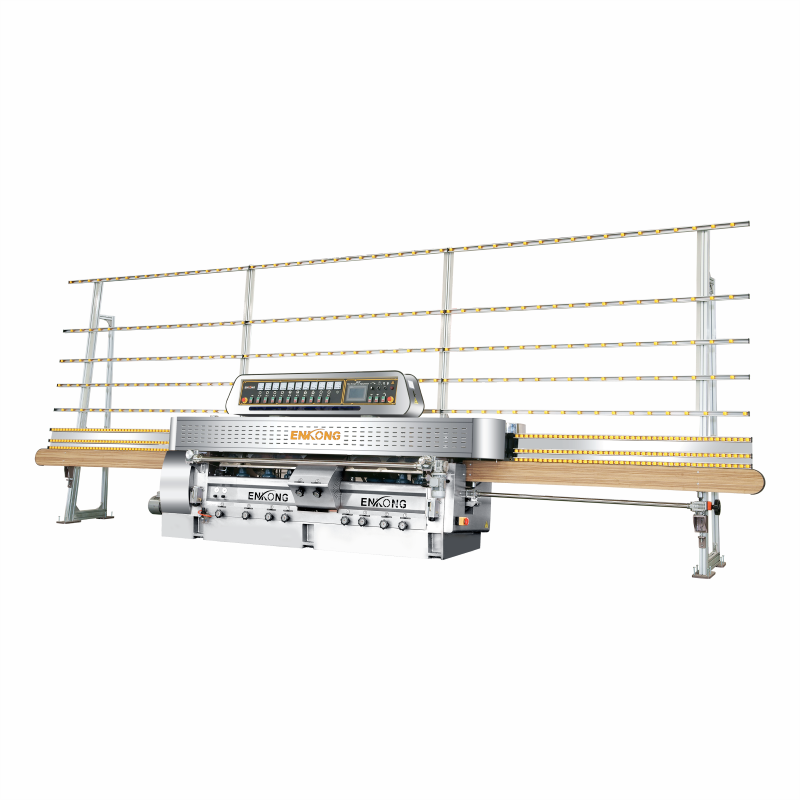

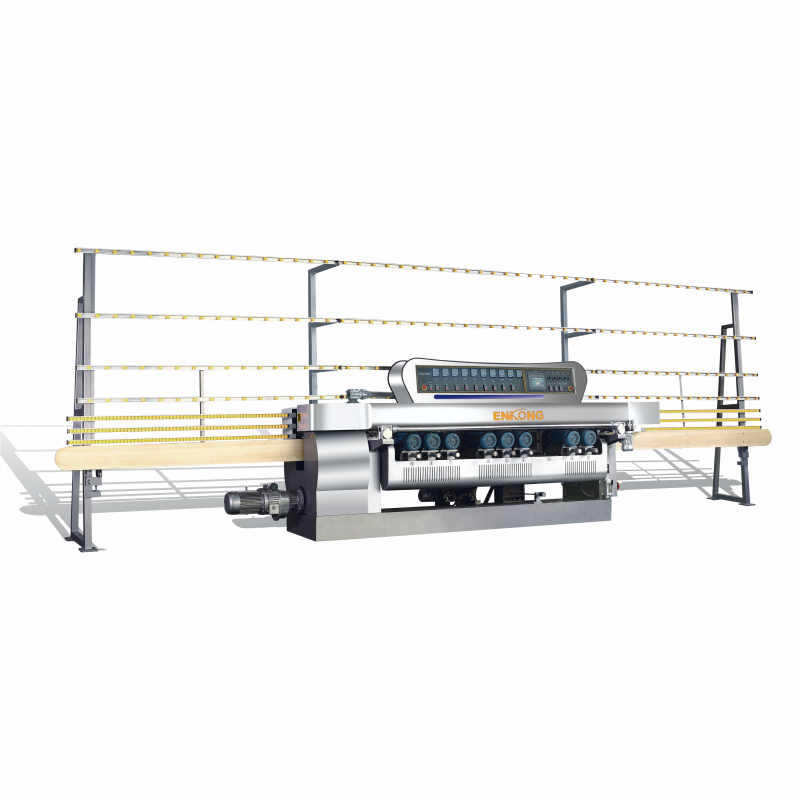

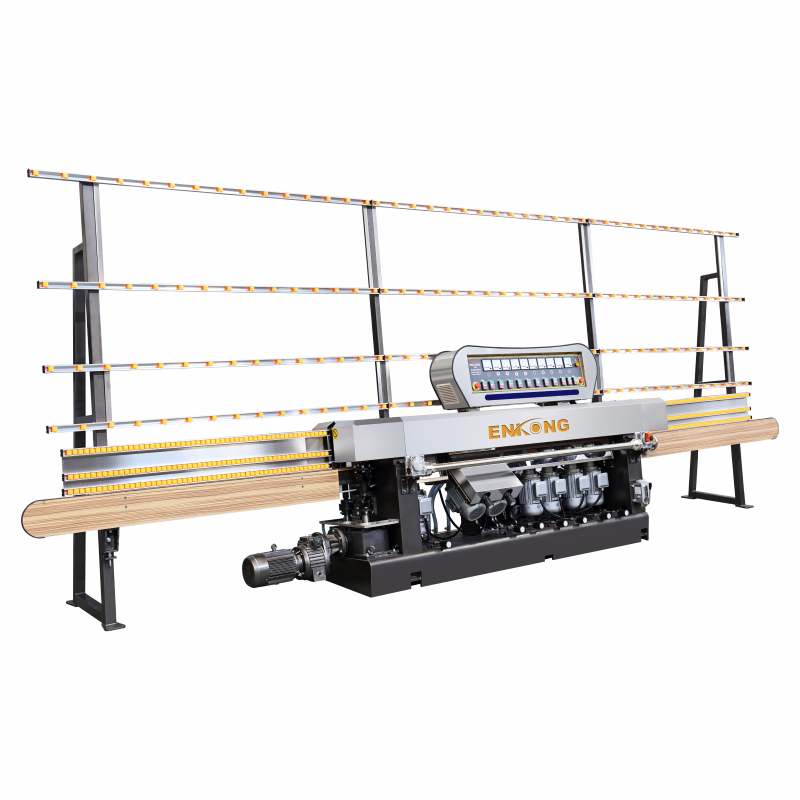

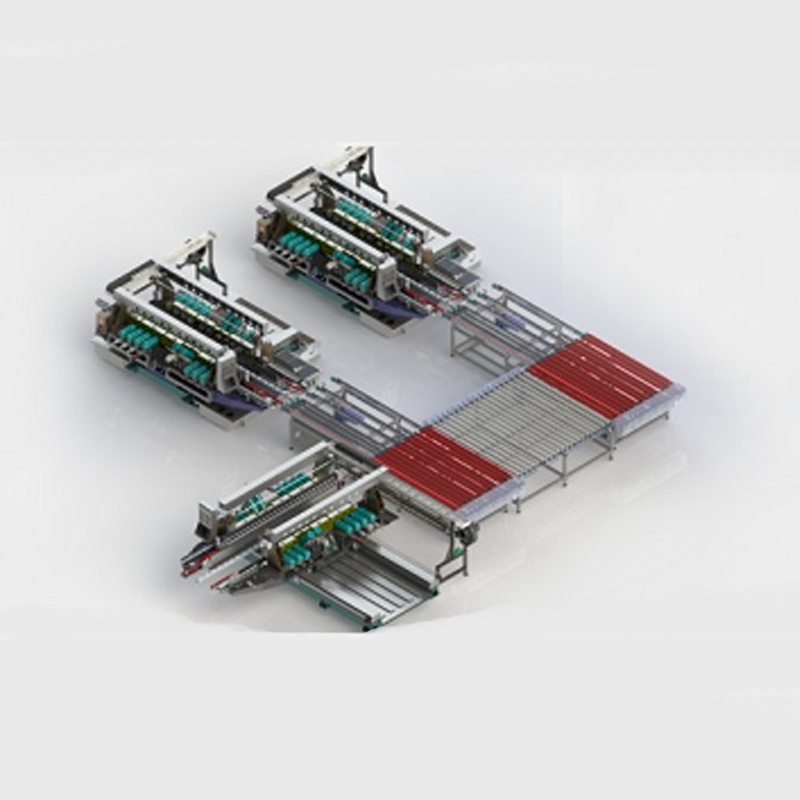

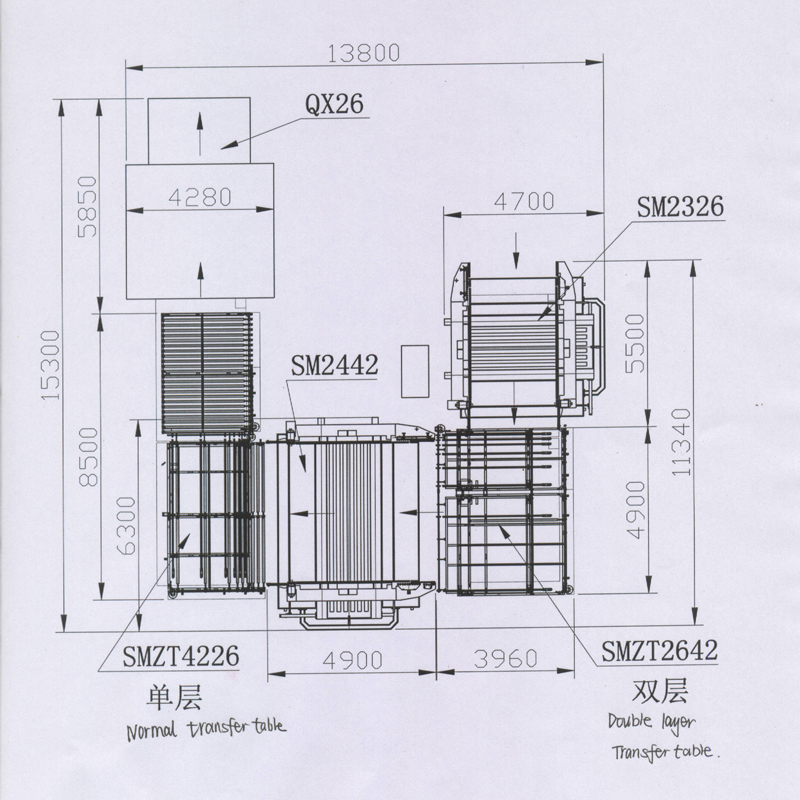

ENKONGS' SM24-Glass Double Straight Line Cutting Machine is a fully automatic, high-speed precision grinding machine used in the glass industry. It is capable of grinding both edges of the glass simultaneously, ensuring a smooth and precise finish.

Send Email

More