General Information:

1.Rough grinding fine grinding, polishing of beveling edge and grinding of bottom edge can be completed at one time.

2.The processing speed is adjustable with variable which offers a wide range of speed selection.

3.Input and output conveyors adopt timing belt which can improve the stability of transmission.

4.The grinding wheels are connected to the motors directly, which is convenient to adjust and maintain

5.Rear beam can be adjusted up and down which is suitable for processing small pieces of glass.

6.Option: Digital control and PLC control

7.The processing speed is adjustable with variator which offers a wide range of speed selection.

8.ENKONGS was set up in 2004, one of the famous manufacturers of glass equipment.We has our own CNC center to processing all machanical parts for our glass machine. Quality control in the house.

9.ENKONGS accepts reasonable custom-made.

-Technical Specifications:

Min. Processing Size: 120x120mm

Min. Processing Size: 120x120mmProcessing Thickness Speed: 3-19mm

Processing Speed: 0-6 m/min

Max. Width of Bevel: 40 mm

Angle: 3-45°

Weight : 4750 KG

Power: 25 KW

Size: 8280X1300X2500mm

Spindle Quantity : 11 PCS

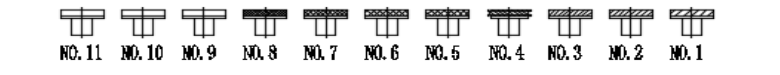

Wheels position: (From input to output end) ←

The wheel disposal of XM371 Glass straight-line beveling machine:

| Spindle No | Function | Model | Wheel |

| NO.1 | Rough grinding | Φ150*Φ12 | Diamond wheel 100 grit |

| NO.2 | Semi-Rough grinding | Φ150*Φ12 | Diamond wheel 140-150 grit |

| NO.3 | Semi-Rough grinding | Φ150*Φ12 | Resin wheel 180grit |

| NO.4 | Bottom line grinding (pencil edge) | Φ175*Φ22*R5 | Diamond wheel 180 grit |

| NO.5 | Semi-fine grinding | Φ150*12*20*13 | Resin wheel 180 grit |

| NO.6 | Semi-fine grinding | Φ150*12*20*13 | Resin wheel 240 grit |

| NO.7 | Semi-fine grinding | Φ150*12*20*13 | Resin wheel 320 grit |

| NO.8 | Semi-fine grinding | Φ150*12*20*13 | Resin wheel 600 grit |

| NO.9 | Polishing | Φ150*Φ105*35 | Wool felt wheel |

| NO.10 | Polishing | Φ150*Φ105*35 | Wool felt wheel |

| NO.11 | Polishing | Φ150*Φ105*35 | Wool felt wheel |

5.The processing center for processing mechanical parts

The front and rear reinforced casting girders,columns and basesare subjected to secondary heat treatment,so that the welding parts have a qualitative change, which can strengthen the hardness and make the machine more durable. Spare parts are processed by CNC gantry machining center,which reduce the cumulative tolerance of the whole assembly and improve the precision of edge grinding.

The edging assemble workshop

The close-up photos and description of edger

The lathe of edger, after grinding, milling ,drilling ,painting . the beams of edgers

Adopt reinforcement design to prevent beam deformation

The front and rear chain plates adopt double chains plus suspension structure, the

clamping force is constant,easy to load and unload.

Swing Angle motor, you can adjust the glass angle you want and it is very convenient;

The processing speed controlled by Stepless motor, But it can be upgrade as Frequency

conversion

Using the ABB grinding motors.

The front and rear corner dubbing motor dragging plate adopts linear sliding friction guide rail with adjust movement smoothly;

Lubrication system on every movements connections.

The water tank for wheels are uses stainless steel,stamped and formed,

without welding, without cracks, more waterproof and the surface is smooth;

each wheel is equipment two pcs of water pipes for cooling;

The watering with two pcs of stainless steel water tanks.

One is for clear water (No.1-8 wheels).

and the other one is for NO.9 (working with cerium)

The electrical elements using ABB /Schneider. The quality is reliable.

It adopts a hand wheel to adjust the glass thickness,which is suitable for the straight-line edging machine only.

There has digital meter on machine panel to adjust the glass thickness. You just need to increase or decrease the parameter you need by the relative switch, then machine can be adjust

automatically.

Company strength

Certifications

Promision

1. The production line can process 3 pieces per minute.

2. The glass can be rotated 45 degrees without the operator manually rotating the glass.

3. Continuous processing of glass sheets of different sizes and the same thickness

4. Can process special-shaped glass.

5. Glass edge production line can be customized according to the needs of the factory.