The glass manufacturing industry is at a crossroads, balancing soaring demand for high-performance glass products with mounting pressure to reduce waste and energy consumption. In this context, the glass production line has emerged as a game-changer, redefining efficiency across glass production lines worldwide. But what specific challenges does this technology address? How do glass high-speed edging equipment and glass deep processing machines collaborate within these systems to unlock new possibilities? And why are industries from aerospace to consumer electronics prioritizing this innovation?

1. The Precision Paradox: How Do Glass Double Edging Production Lines Solve Modern Manufacturing Challenges?

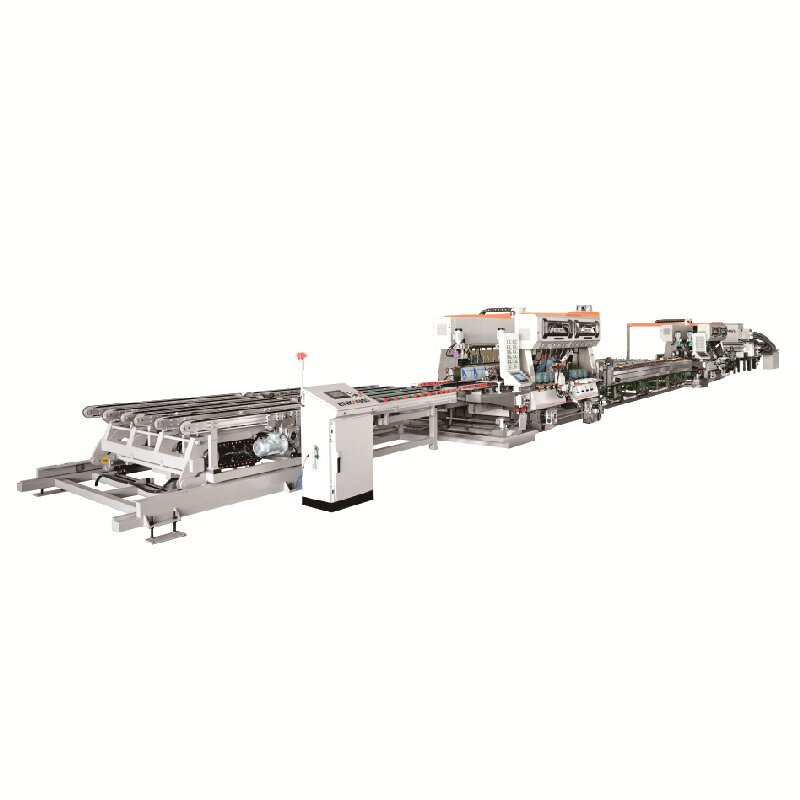

Modern glass production lines face a dual mandate: produce faster and achieve micron-level precision. Traditional single-edge processing systems struggle to meet these demands, often leading to bottlenecks. Enter the glass double edging production line, engineered to process both edges of a glass sheet simultaneously. By integrating glass high-speed edging equipment, these systems slash cycle times while maintaining tolerances as tight as ±0.03 mm—critical for applications like OLED displays or optical lenses.

Key Innovations Driving Precision:

Dual-Axis Synchronization: Independent servo motors control each grinding head, ensuring uniform pressure across both edges even on warped or ultra-thin glass.

Real-Time Feedback Loops: Laser sensors detect edge irregularities mid-process, adjusting grinding parameters instantaneously—a feature borrowed from advanced glass deep processing machines.

Adaptive Cooling Systems: High-speed operations generate heat, but integrated liquid cooling prevents thermal distortion, a common issue in older glass production lines.

For example, a Taiwanese electronics supplier reduced edge-defect rates by 90% after replacing legacy machines with a glass production line, enabling them to meet Apple’s stringent standards for iPad cover glass.

2. Synergy with Glass Deep Processing Machines: Crafting End-to-End Workflows

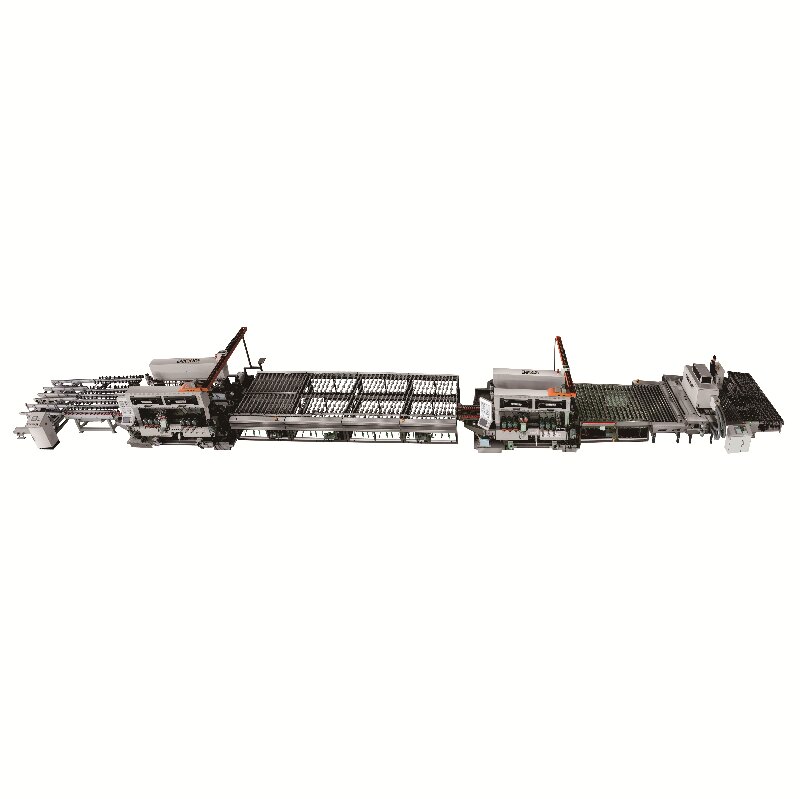

No glass production line operates in isolation. The true power of a glass double edging production line lies in its integration with glass deep processing machines, creating a seamless pipeline from raw glass to finished product.

Critical Integration Points:

Pre-Edging Preparation: Before reaching the glass high-speed edging equipment, glass sheets are cut to near-net shape using CNC cutting machines, minimizing material waste.

Post-Edging Enhancements: After edge polishing, glass may move to glass deep processing machines for coating (e.g., anti-glare layers) or engraving (e.g., corporate logos).

Quality Assurance: Automated inspection systems, often embedded within glass production lines, scan edges post-processing to ensure compatibility with downstream tempering or lamination.

In the automotive sector, Tesla’s Gigafactories use this integrated approach: glass sunroofs edged via glass double edging production lines are directly fed into vacuum coating glass deep processing machines, applying UV-resistant films without intermediate handling.

3. Glass High-Speed Edging Equipment: The Engine Behind the Revolution

At the core of every glass double edging production line is its glass high-speed edging equipment—a marvel of mechanical and digital engineering. These systems combine brute-force grinding power with AI-driven finesse.

Breakthrough Technologies:

Diamond-Embedded Abrasives: Synthetic diamond wheels, lasting 3x longer than traditional abrasives, maintain sharpness even at 10,000 RPM—key for glass high-speed edging equipment.

Predictive Analytics: Machine learning algorithms analyze vibration and sound data to predict wheel wear, reducing unplanned downtime in glass production lines by 35%.

Green Machining: Closed-loop water filtration systems recycle 95% of coolant, aligning with eco-standards for glass deep processing machines.

A case in point: A Saudi Arabian manufacturer of mosque glass domes achieved a 50% reduction in water usage after adopting glass high-speed edging equipment with dry grinding capabilities, crucial in arid regions.

4. Versatility Unleashed: Industries Transformed by Glass Double Edging Production Lines

The glass double edging production line isn’t confined to a single niche—it’s a cross-industry enabler. Below are sectors where its impact is most profound:

A. Architecture & Construction

Curtain Walls: Skyscrapers like Shanghai Tower use double-edged glass panels for seamless joints, processed by glass high-speed edging equipment to withstand typhoon-force winds.

Smart Windows: Post-edging, glass deep processing machines apply electrochromic coatings, enabling glass that tints on demand.

B. Medical Technology

Labware & Surgical Glass: Edges polished to Ra ≤0.1 μm (achievable only by glass double edging production lines) prevent bacterial adhesion, critical for autoclave-resistant lab equipment.

C. Renewable Energy

Perovskite Solar Cells: Ultra-smooth edges from glass high-speed edging equipment minimize light scattering, boosting panel efficiency by 5–8%.

A German industrial consortium recently credited their glass production line upgrades—including a glass double edging production line—for cutting solar glass defect rates by 70%, securing contracts worth €200 million.

5. Overcoming Obstacles: Tackling the Limitations of Current Systems

While revolutionary, glass double edging production lines aren’t without challenges. Understanding these hurdles is key to maximizing ROI.

A. Material Compatibility

Problem: Brittle substrates like borosilicate glass may chip under high-speed grinding.

Solution: Advanced glass high-speed edging equipment now employ variable frequency drives (VFDs) to dynamically adjust RPM based on glass type.

B. Energy Intensity

Problem: Older glass production lines consume up to 30 kW per hour during peak edging.

Solution: Hybrid systems combining glass double edging production lines with regenerative braking recover 15% of energy, as seen in Japan’s AGC Inc.

C. Skill Gaps

Problem: Operating AI-enhanced glass deep processing machines requires specialized training.

Solution: Manufacturers like Bystronic offer VR simulators to train technicians, reducing onboarding time by 50%.

6. The Future Is Double-Edged: Emerging Trends in Glass Production Lines

As Industry 4.0 reshapes manufacturing, glass double edging production lines are evolving through three key trends:

1. Cobot Integration

Collaborative robots (cobots) now load/unload glass into glass high-speed edging equipment, working alongside humans without safety cages. Stäubli’s TX2 series, for instance, handles 200 kg glass sheets with 0.01 mm repeatability.

2. Digital Twins

Virtual replicas of glass production lines allow operators to simulate edge grinding processes, optimizing parameters before physical runs. Pilkington reported a 20% yield increase after implementing Siemens’ digital twin software.

3. Circular Economy

Grinding sludge from glass double edging production lines—once landfill-bound—is now repurposed into construction materials. Saint-Gobain’s “Zero Waste” initiative recycles 98% of byproducts from glass deep processing machines.

Is Your Facility Ready to Embrace the Double Edging Era?

The glass double edging production line represents more than an upgrade—it’s a strategic pivot toward sustainable, high-yield manufacturing. By harmonizing with glass high-speed edging equipment and glass deep processing machines, this technology addresses the trifecta of cost, quality, and scalability.

From enabling razor-thin foldable smartphones to earthquake-resistant architectural marvels, the applications are limitless. As global demand for precision glass surges, manufacturers who delay adopting glass double edging production lines risk obsolescence. The question isn’t whether to invest, but how swiftly you can integrate this linchpin technology into your glass production line.