Glass processing is a crucial aspect of the glass manufacturing industry, and the glass edging machine plays a vital role in shaping and finishing glass products. There are two primary types of glass edging machines: manual and automated. This article will explore the key differences between these two types of glass grinding machines, focusing on their functionality, efficiency, precision, and overall capabilities.

1. Functionality

Manual Glass Edging Machine:

A manual glass edging machine, also known as a glass grinding machine, is designed for smaller-scale glass processing operations. It typically requires an operator to manually guide the glass through the machine, which has a series of abrasive wheels that grind and shape the edges of the glass. This type of machine is suitable for simple, straight-edged cuts and basic shapes.

Automated Glass Edging Machine:

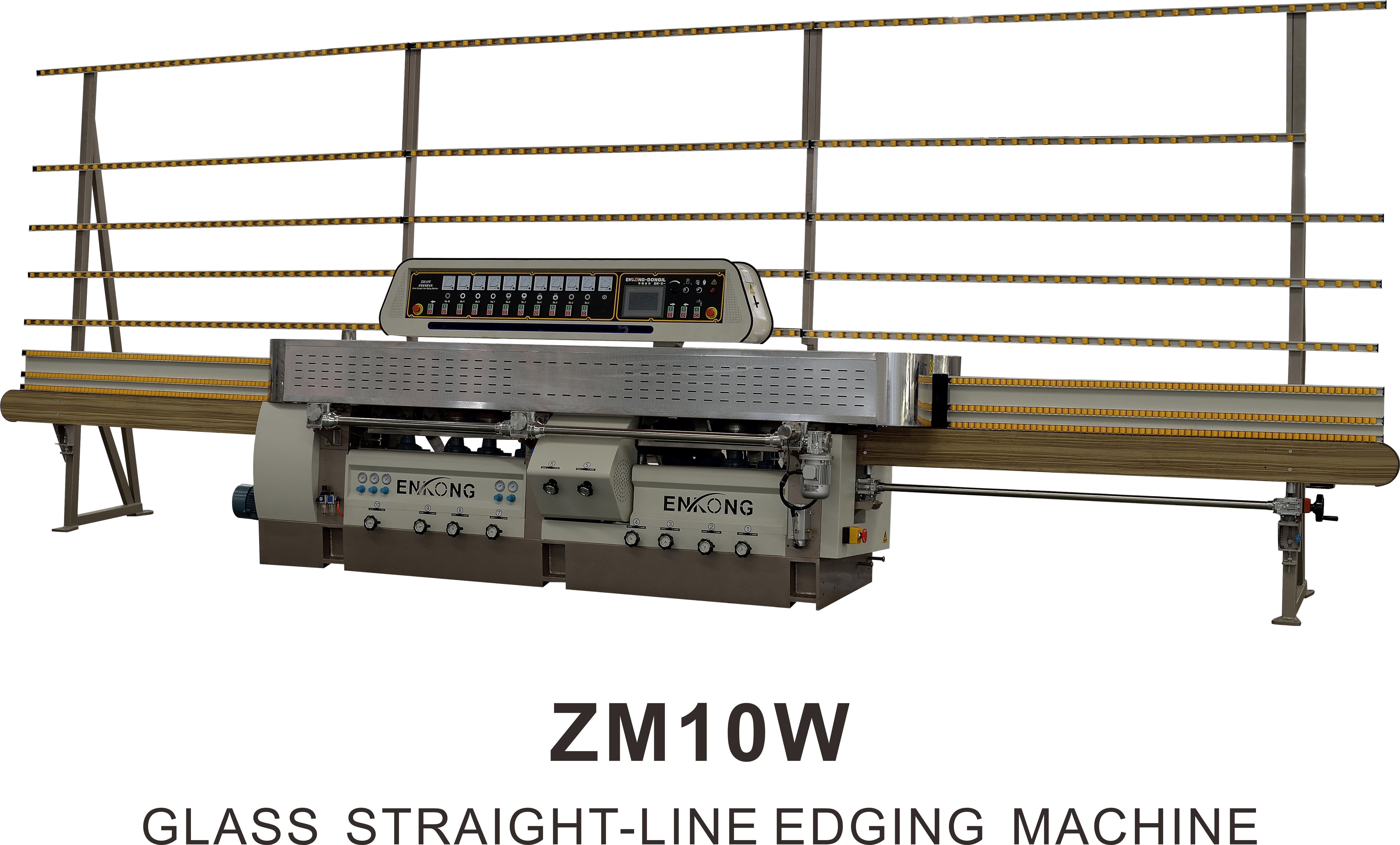

An automated glass edging machine, also referred to as a glass processing machine or glass edger, is designed for larger-scale glass manufacturing operations. It features advanced technology that automates the glass grinding process, allowing for more complex shapes and higher precision. The machine can be programmed to perform various tasks, such as cutting, grinding, and polishing, with minimal operator intervention.

2. Efficiency

Manual Glass Edging Machine:

Manual glass edging machines are generally less efficient than their automated counterparts. The process is slower, as it relies on the operator's manual input. Additionally, the operator must frequently stop and start the machine to adjust the glass and abrasive wheels, further reducing efficiency.

Automated Glass Edging Machine:

Automated glass edging machines offer significantly higher efficiency due to their advanced technology and automation capabilities. These machines can process glass products at a much faster rate, reducing production time and increasing output. Furthermore, the automated process minimizes the need for operator intervention, allowing for continuous operation.

3. Precision

Manual Glass Edging Machine:

Manual glass edging machines typically have less precision than automated machines. The operator's manual input can lead to inconsistencies in the glass edges, resulting in a lower quality finish. This can be particularly problematic for complex shapes and intricate designs.

Automated Glass Edging Machine:

Automated glass grinding machines are designed to provide high precision and accuracy. The advanced technology allows for precise control over the glass processing parameters, ensuring consistent and high-quality results. This is especially important for applications that require complex shapes and tight tolerances.

4. Glass Equipment and Accessories

Manual Glass Edging Machine:

Manual glass grinding machines usually have fewer accessories and glass equipment options compared to automated machines. This is because the simpler design and functionality of manual machines do not require as many specialized components.

Automated Glass Edger:

Automated glass grinding machines come with a wide range of accessories and glass equipment, allowing for greater versatility and functionality. These machines can be equipped with various types of abrasive wheels, polishing pads, and cutting tools to accommodate different glass processing requirements.

5. Cost

Manual Glass Edger:

Manual glass edgers are generally less expensive than automated machines. They are a more cost-effective option for smaller-scale glass processing operations or businesses with limited budgets.

Automated Glass Edger:

Automated glass grinding machines are more expensive due to their advanced technology and capabilities. However, they offer a better return on investment for larger-scale glass manufacturing operations, as they can significantly increase production efficiency and quality.

The key differences between manual and automated glass processing machines lie in their functionality, efficiency, precision, glass equipment options, and cost. While manual machines are suitable for smaller-scale operations and offer a more affordable option, automated machines provide higher efficiency, precision, and versatility, making them ideal for larger-scale glass manufacturing. Businesses must carefully consider their specific needs and budget when choosing between these two types of glass processing machines.

One of the key differences between manual and automated glass processing machines is the level of precision they offer. Automated machines are capable of achieving extremely precise results, with minimal variation between pieces. This is especially important in industries such as automotive or architectural glass, where consistency and accuracy are essential. Manual machines, while capable of producing high-quality results, may not be able to match the level of precision that automated machines can achieve. Another key difference between manual and automated glass edging machines is the cost. Automated machines are typically more expensive to purchase and maintain than manual machines. However, the increased efficiency and productivity that automated machines offer can often justify the higher initial investment. In addition, automated machines can reduce labor costs by requiring fewer operators to oversee the production process.