Introduction

The glass manufacturing sector is experiencing unprecedented growth, fueled by advancements in automation, sustainability, and precision engineering. Central to this evolution are three groundbreaking technologies: the glass double edger, glass processing machine, and glass edger. These systems are redefining efficiency across industries, from architectural glazing to consumer electronics, by delivering unmatched speed, accuracy, and adaptability. This report explores the technical innovations, market trends, and transformative applications of these machines, positioning them as indispensable tools in modern manufacturing with glass edger.

Chapter 1: The Technological Foundations of Modern Glass Processing

1.1 The Rise of the Glass Double Edger

The glass double edger has revolutionized edge-finishing processes by enabling simultaneous grinding and polishing of both sides of glass panels. Unlike conventional single-edge machines, this system reduces cycle times by up to 50% while maintaining micron-level precision. For instance, a leading U.S. manufacturer of shower enclosures reported a 40% increase in output after integrating a glass double edger with AI-powered pressure adjustment. Such machines are now critical for producing automotive windshields and smartphone screens, where edge consistency is paramount.

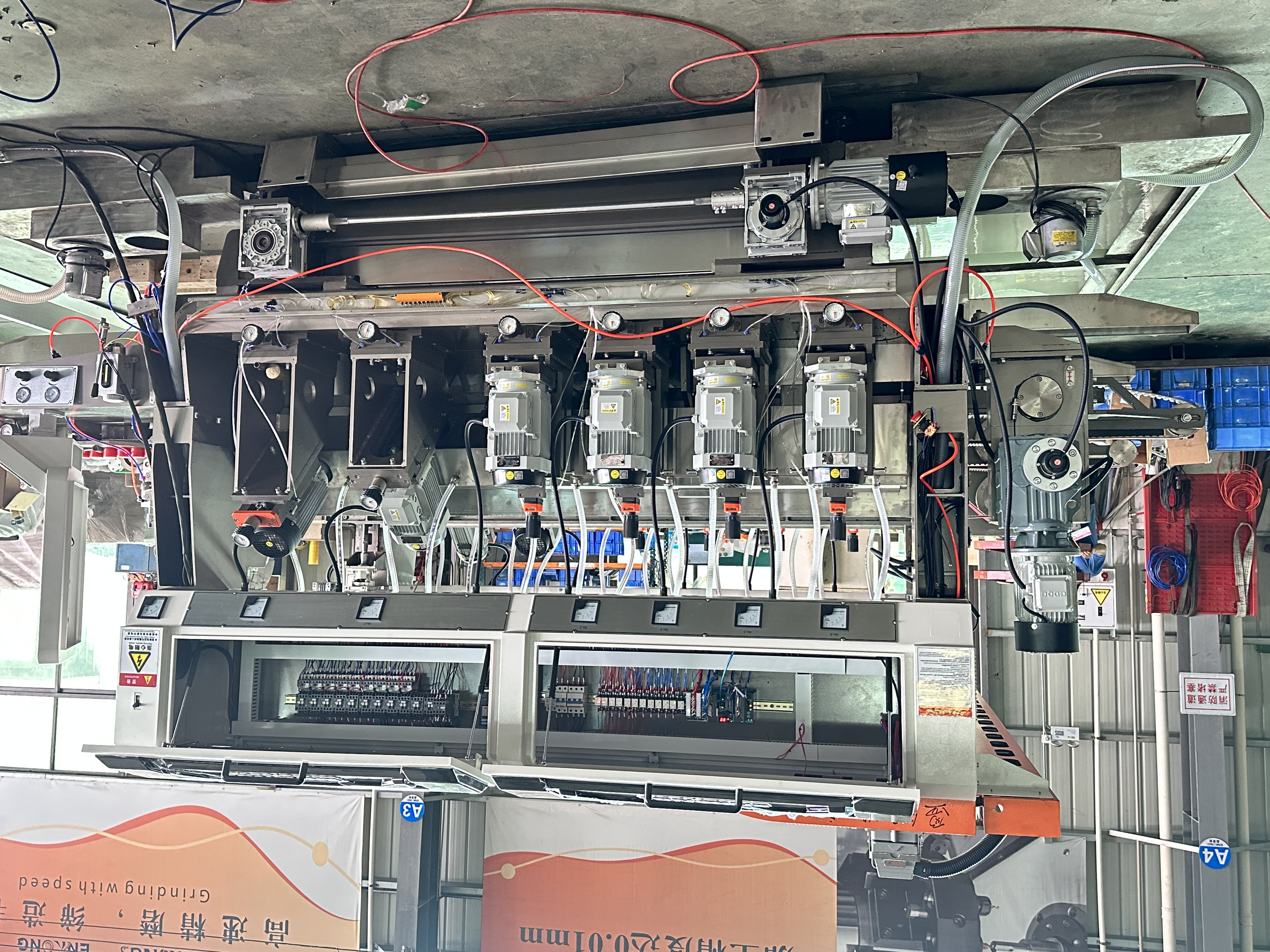

1.2 Glass Processing Machines: The Backbone of Industrial Production

A glass processing machine serves as a multifunctional hub for cutting, drilling, tempering, and coating glass. Modern variants incorporate laser-guided alignment and IoT connectivity, allowing real-time adjustments based on material thickness or environmental conditions. A case in point is a German factory that deployed a glass processing machine with integrated CO₂ laser cutting, achieving a 99.8% yield rate for photovoltaic glass.

1.3 The Versatility of Glass Edgers

The glass edger, a cornerstone of glass finishing, specializes in creating smooth, safe edges for applications ranging from tabletops to medical devices. Recent advancements include diamond-embedded grinding heads and water-cooling systems that minimize thermal stress. A Japanese electronics firm, for example, leveraged a high-precision glass edger to produce ultra-thin edges for augmented reality lenses, slashing rejection rates by 35%.

Chapter 2: Cutting-Edge Innovations Driving Industry Adoption

2.1 AI and Machine Learning Integration

Next-gen glass double edgers now employ glass edger learning algorithms to predict tool wear, automatically adjusting grinding parameters to maintain consistency. Similarly, glass processing machines use computer vision to detect micro-cracks during tempering, ensuring compliance with ISO safety standards. These innovations reduce downtime and enhance product reliability with glass edger.

2.2 Sustainability in Focus

Energy efficiency is a hallmark of modern glass edgers. A Swiss manufacturer recently unveiled a glass edger with regenerative braking, cutting energy consumption by 30%. Meanwhile, glass processing machines are adopting closed-loop water systems, recycling 95% of coolant and reducing wastewater generation. Such features align with global ESG (Environmental, Social, Governance) mandates.

2.3 Customization for Niche Applications

From curved balcony railings to bulletproof panels, the adaptability of glass double edgers is reshaping design possibilities. A landmark project iof glass edgern Dubai utilized a customized glass processing machine to fabricate 3D-textured glass facades, completing the installation six weeks ahead of schedule with glass edger.

Chapter 3: Market Dynamics and Sector-Specific Demand

3.1 Construction and Architecture

The global construction glass market, projected to reach $130 billion by 2027, relies heavily on glass double edgers for producing laminated and insulated glass units. Skyscrapers like Shanghai Tower used glass processing machines to create 12-meter-tall panels with zero edge defects.

3.2 Automotive and Aerospace

Electric vehicles demand lightweight, aerodynamically optimized glass. Tesla’s Cybertruck, for instance, features windows processed by a glass edger capable of handling 10mm-thick armored glass. Aerospace applications are emerging too, with Boeing exploring glass processing machines for cockpit canopies.

3.3 Consumer Electronics

The foldable smartphone boom has spiked demand for ultra-durable edges. Samsung’s latest Galaxy Fold employed a glass double edger with nano-polishing technology to achieve a 0.1mm edge radius, enhancing durability against impact.

Chapter 4: Global Case Studies Demonstrating Operational Excellence

4.1 Case Study 1: Elevating Architectural Ambitions in Singapore

A luxury resort in Singapore deployed a glass processing machine to produce 500 curved glass panels for its infinity pool. The glass edger’s robotic arms and adaptive software reduced manual handling by 70%, ensuring flawless edges despite Singapore’s high humidity.

4.2 Case Study 2: Automotive Innovation in Germany

BMW partnered with a Bavarian glass supplier to use a glass double edger for its iX electric SUV’s panoramic roof. The glass edger’s dual-axis grinding system eliminated optical distortions, achieving a 50% faster production rate than traditional methods.

4.3 Case Study 3: Medical Precision in the United States

A medical device company in California adopted a glass edger with ultrasonic cleaning to process lab-on-a-chip glass slides. The result? A 90% reduction in contamination-related recalls, saving $2.8 million annually.

Chapter 5: Challenges and Future Trajectories

5.1 Overcoming Technical Barriers

While glass double edgers excel in speed, their high upfront costs deter SMEs. Leasing models and government subsidies are emerging as solutions. Meanwhile, glass edgers face challenges in processing hybrid materials like glass-ceramic composites, spurring R&D into multi-material compatible systems.

5.2 The AI-Driven Factory of Tomorrow

Future glass processing machines may feature autonomous decision-making via digital twins, simulating processes before execution. Similarly, glass double edgers could integrate quantum sensors for sub-micron accuracy, catering to semiconductor-grade glass.

5.3 Circular Economy Initiatives

By 2030, manufacturers aim to retrofit glass edgers to process 100% recycled glass without quality loss. Pilot projects in Scandinavia already use glass processing machines to upcycle demolition waste into construction-grade panels, reducing landfill dependence.

Conclusion

The glass double edger, glass processing machine, and glass edger represent more than incremental upgrades—they are pillars of the Fourth Industrial Revolution. As industries prioritize speed, sustainability, and precision, these machines will remain at the vanguard of innovation. For stakeholders, embracing these technologies isn’t just a strategic advantage; glass edger a necessity in a world where glass is the material of the future.