ENKONGS double glass edging machine specialized equipment is engineered to simultaneously process both edges of a glass sheet, delivering precise grinding, beveling, and polishing. Automatic high speed processing machine is indispensable for producing glass products that require uniform and aesthetically pleasing edges, such as mirrors, tempered glass, and decorative glass utilized in architectural and automotive applications. WhatsAPP+86 188 2308 1140 Email:jmek@enkongs.net

The glass processing industry is undergoing a significant transformation, driven by an increasing demand for expedited throughput and enhanced edge quality on both sides of the glass simultaneously. This trend is particularly prominent in sectors that require high-volume production and consistent precision, such as the home appliance and architectural glass markets. At the forefront of this evolution is the advanced glass high speed double edging machine, a technological innovation designed to redefine productivity standards. Unlike traditional single-edge processors, this equipment fundamentally optimizes production workflows. The core innovation of any modern glass high speed double edging machine lies in its synchronized dual-head system, which enables the concurrent processing of two parallel edges in a single pass. The market has witnessed substantial adoption of this technology, especially with models specifically engineered as home appliance glass double edging machines, calibrated to meet the precise thickness and dimensional requirements for products like oven doors and refrigerator shelves.

For manufacturers specializing in components for the consumer goods sector, the home appliance glass double edging machine has become an essential asset. This variant of double-edging technology is tailored to address the high-volume and consistent-quality demands associated with producing glass items such as microwave plates, washing machine lids, and cooker tops. A well-engineered home appliance glass double edging machine typically features adjustable feeding systems that accommodate various standard sizes without lengthy changeover times, ensuring seamless integration into fast-paced production lines. While a standard glass double side grinding machine provides the foundational capabilities, the specific configuration of a home appliance glass double edging machine is designed to achieve the precise finish required for these domestic products. This often involves specialized polishing sequences that enhance aesthetic appeal.

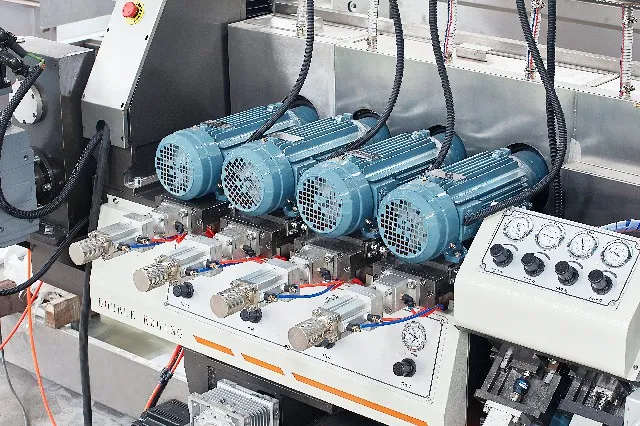

The fundamental technology enabling this dual-edge processing is encapsulated in the robust design of the glass double side grinding machine. This category of machinery serves as the backbone of operations, where actual grinding, beveling, and polishing take place. A high-performance glass double side grinding machine features independent spindles on each side, each equipped with a sequence of diamond grinding wheels and felt polishing wheels. The sophistication inherent in a glass double side grinding machine is evident through its precise alignment systems and stable mechanical structure, which mitigate vibration and ensure that both edges are mirror images of one another in terms of profile and finish. The evolution of this machinery has been instrumental in making advanced edging techniques accessible, providing reliable mechanical action that can be further leveraged by more automated and faster glass high speed double edging machines for maximum productivity.

The synergy between speed and precision is exemplified in the operation of modern glass high speed double edging machines. These systems are integrated with programmable logic controllers (PLCs) and human-machine interface (HMI) panels, allowing operators to store hundreds of edge profiles tailored for various products. The automation within a glass high speed double edging machine manages critical parameters such as feed speed, grinding head pressure, and coolant flow—ensuring consistent results from the first piece to subsequent units. This level of control is essential for a home appliance glass double edging machine where brand consistency and product quality are paramount. The mechanical foundation provided by the glass double side grinding machine is significantly enhanced through the integration of intelligent software, resulting in a cohesive system that optimizes both speed and accuracy without compromise.

In addition to these advantages, sustainability and operational cost reduction are key factors driving the adoption of this technology. The enclosed design of a glass high speed double edging machine typically features an efficient coolant and water recycling system. This not only minimizes water consumption but also effectively contains glass dust, contributing to a cleaner and more environmentally friendly workshop environment. Furthermore, the durability and low maintenance requirements of essential components—such as heavy-duty spindles and linear guides—ensure an extended service life while reducing the total cost of ownership. When assessing a home appliance glass double edging machine, energy efficiency and reduced consumable usage emerge as critical considerations for calculating return on investment for high-volume manufacturers.

In conclusion, the integration of double-sided edging technology marks a significant advancement within the glass processing industry. The glass high speed double edging machine exemplifies an unwavering commitment to achieving unparalleled productivity, while specialized home appliance models cater specifically to the unique demands of this vital market segment. At their core lies the reliable and precise glass double side grinding machine, which performs essential material modification tasks. As demand for faster production cycles and flawless glass components continues to escalate, these advanced edging solutions are poised to establish new standards among progressive manufacturers worldwide, setting unprecedented benchmarks in glass fabrication capabilities.