The global glass processing industry is undergoing a transformative phase, driven by technological advancements and surging demand for precision-engineered glass components. At the forefront of this revolution are innovations such as the high-speed double edging machine, home appliance glass machine, and glass double edging machine. These cutting-edge systems are redefining efficiency, accuracy, and scalability in sectors ranging from construction to consumer electronics. This report delves into the technical prowess, market impact, and future potential of these machines, emphasizing their role in shaping modern manufacturing ecosystems.

Chapter 1: The Evolution of Glass Edging Technology

1.1 The Emergence of High-Speed Double Edging Machines

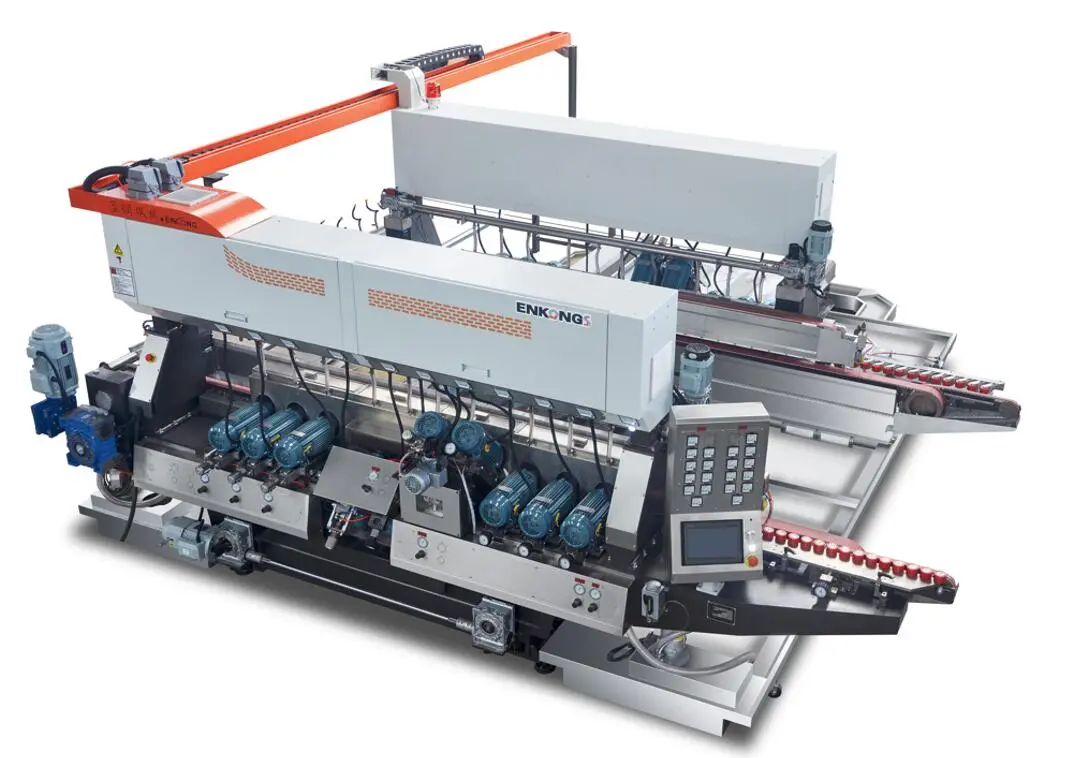

The high-speed double edging machine has emerged as a game-changer for industries requiring rapid, high-precision glass finishing. Unlike traditional single-edge edgers, this machine processes both edges of glass panels simultaneously, slashing production time by up to 60%. Equipped with diamond abrasive wheels and AI-driven calibration systems, modern high-speed double edging machines achieve tolerances as tight as ±0.1mm, making them indispensable for automotive and architectural glass applications.

1.2 Home Appliance Glass Machines: Meeting Consumer Demands

As smart home devices proliferate, the home appliance glass machine has become critical for producing sleek, durable glass components for refrigerators, ovens, and washing machines. These machines integrate advanced tempering and coating technologies to enhance scratch resistance and thermal stability. For instance, a leading manufacturer in Germany reported a 30% increase in output after adopting a next-gen home appliance glass machine with automated quality inspection modules.

1.3 Glass Double Edging Machines: Versatility Redefined

The glass double edging machine bridges the gap between speed and versatility. Capable of handling glass thicknesses from 3mm to 25mm, it supports beveled, flat, and rounded edge profiles. A case study from a Chinese solar panel producer highlighted how upgrading to a glass double edging machine reduced material waste by 22%, underscoring its economic and environmental benefits.

Chapter 2: Technical Innovations Driving Adoption

2.1 AI and IoT Integration

Modern high-speed double edging machines now incorporate IoT sensors to monitor wear on grinding wheels in real time, enabling predictive maintenance. Similarly, home appliance glass machines leverage machine vision to detect micro-fractures, ensuring zero-defect outputs. These advancements align with Industry 4.0 standards, fostering seamless integration into smart factories.

2.2 Energy Efficiency and Sustainability

The latest glass double edging machines consume 35% less energy than predecessors, thanks to regenerative braking systems and optimized coolant circulation. Meanwhile, home appliance glass machines are adopting water recycling mechanisms, reducing consumption by 50%. Such innovations position these machines as pillars of sustainable manufacturing.

2.3 Customization Capabilities

From smartphone screens to jumbo-sized architectural panels, the adaptability of high-speed double edging machines is unparalleled. For example, a U.S.-based contractor customized a glass double edging machine to process curved edges for a flagship skyscraper, achieving a project deadline that was previously deemed unattainable.

Chapter 3: Market Dynamics and Growth Projections

3.1 Surging Demand in the Appliance Sector

The global home appliance market, projected to reach $761 billion by 2030, is a key driver for home appliance glass machines. Brands like Samsung and LG are investing heavily in these systems to meet consumer preferences for minimalist, glass-heavy designs.

3.2 Automotive and Construction Applications

Electric vehicles (EVs) and green buildings are fueling demand for high-speed double edging machines. Tesla’s recent partnership with a glass processor to supply lightweight, edge-finished panoramic roofs exemplifies this trend.

3.3 Regional Insights

Asia-Pacific dominates the glass double edging machine market, accounting for 48% of global sales. Europe follows closely, with stringent safety standards pushing manufacturers to adopt advanced edging solutions.

Chapter 4: Case Studies: Success Stories Across Industries

4.1 Case Study 1: Precision in Electronics

A Japanese electronics giant deployed a high-speed double edging machine to produce ultra-thin glass for foldable smartphones. The result? A 40% reduction in cycle time and a defect rate below 0.01%.

4.2 Case Study 2: Reinventing Kitchen Appliances

An Italian luxury appliance brand utilized a home appliance glass machine to craft oven doors with anti-reflective coatings. Sales surged by 18% post-launch, attributed to the product’s aesthetic and functional superiority.

4.3 Case Study 3: Solar Energy Breakthroughs

A Canadian solar firm integrated a glass double edging machine to process tempered glass for photovoltaic panels. The move cut production costs by 15%, enabling competitive pricing in emerging markets.

Chapter 5: Challenges and Future Outlook

5.1 Addressing Technical Limitations

While high-speed double edging machines excel in speed, their sensitivity to glass composition remains a hurdle. R&D teams are exploring adaptive algorithms to overcome this.

5.2 The Road Ahead: Automation and AI

Future iterations of home appliance glass machines may feature fully autonomous loading/unloading systems, while glass double edging machines could adopt quantum computing for real-time error correction.

5.3 Sustainability Goals

By 2030, manufacturers aim to make high-speed double edging machines carbon-neutral through renewable energy integration. Similarly, glass double edging machines will prioritize circular economy principles, recycling 90% of grinding byproducts.

Conclusion

The high-speed double edging machine, home appliance glass machine, and glass double edging machine are not merely tools but catalysts for industrial progress. As technology evolves, these systems will continue to push the boundaries of what’s possible in glass processing, delivering unmatched precision, efficiency, and sustainability. For manufacturers worldwide, investing in these innovations isn’t optional—it’s imperative to stay competitive in an increasingly glass-centric world.