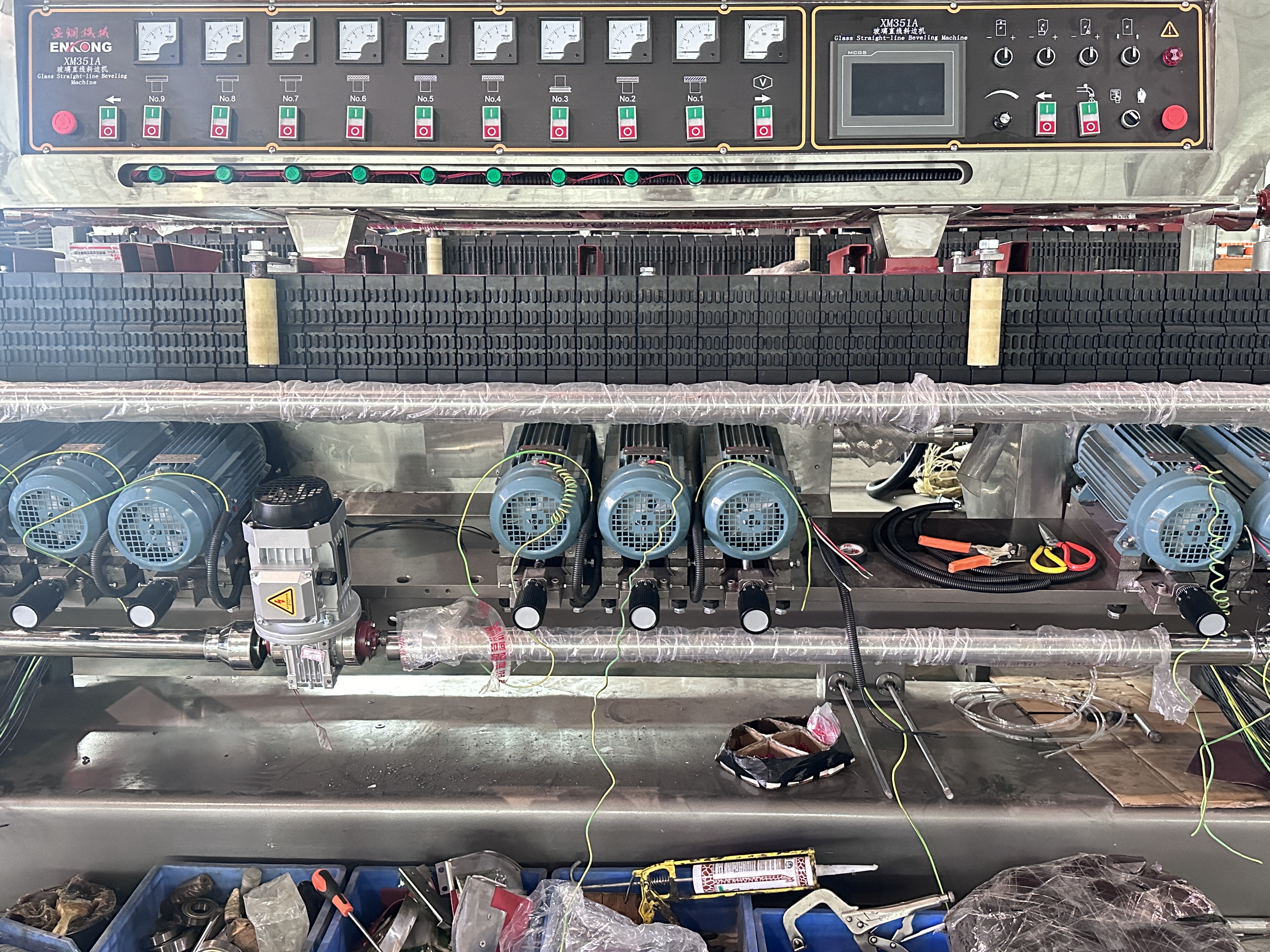

ENKONGS XM351A Glass Straight-line Beveling Machines is used for grinding bevel and bottom edge of glass with different size and thickness. Rough grinding, fine grinding, polishing of bevel and grinding of bottom edge can be completed in one time. It is easy to adjust the feeding of motor in the all and the one and beveling angle while glass thickness is being changed. Same thickness of glass sheet can be process continually.

In an era where architectural brilliance and artisanal craftsmanship converge with industrial efficiency, our company proudly unveils a transformative suite of glass processing solutions designed to unlock unprecedented creative and productive potential. We present our state-of-the-art Glass Beveling Machine, the artistically inclined mosaic glass processing machine, the high-precision Glass Straight Line Beveling Machine, and the versatile powerhouse glass beveling machine. This formidable quartet represents the pinnacle of specialized engineering, meticulously crafted to address the soaring demand for decorative, architectural, and functional glass elements that combine stunning visual impact with flawless execution. These are not mere machines; they are comprehensive systems engineered to empower designers, architects, and fabricators to push boundaries, reduce production bottlenecks, minimize waste, and consistently deliver breathtaking results that captivate the eye and stand the test of time.

The Artisan's Touch, Engineered: The glass straight line beveling machine

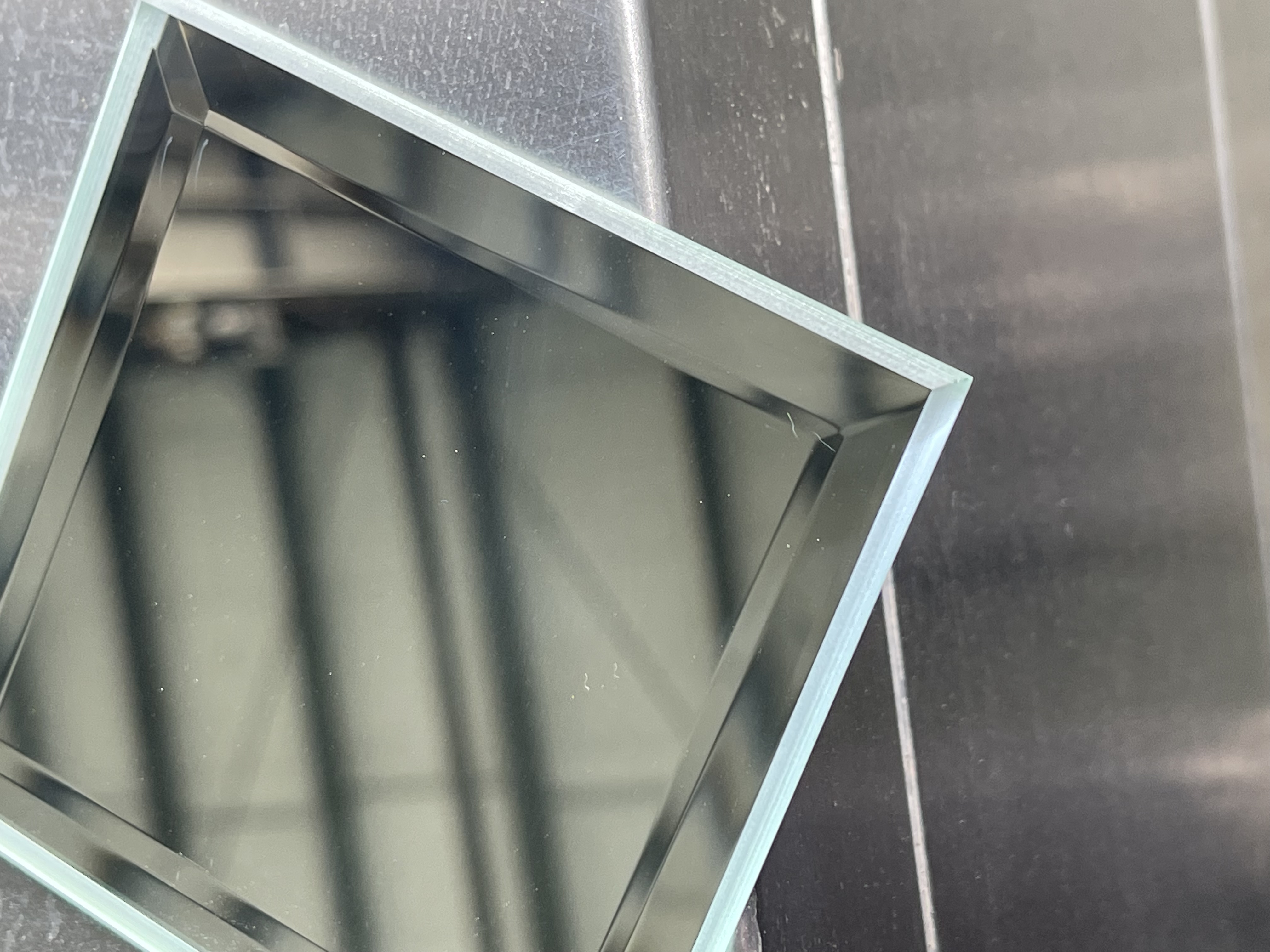

At the core of creating luminous, sophisticated glass elements lies the glass beveling machine. This versatile system is engineered for fabricators who demand both artistic freedom and industrial reliability when producing beveled edges of exceptional clarity and depth. Imagine transforming ordinary glass sheets into radiant features where light dances along precisely angled facets – this is the domain of the Glass Beveling Machine. Its power stems from a sophisticated multi-axis grinding and polishing system capable of producing a vast spectrum of bevel profiles, from delicate, narrow angles to dramatic, wide facets, all with a flawless, distortion-free finish. The glass beveling machine excels at handling complex shapes – circles, ovals, curves, and irregular polygons – making it indispensable for custom mirrors, decorative panels, tabletops, and intricate signage. Advanced pressure control ensures consistent material removal across the entire bevel length, even on varying thicknesses or delicate glass types. Integrated coolant management keeps temperatures stable, preventing micro-cracks and ensuring optical perfection. Digital controls allow operators to store and recall countless bevel profiles, enabling rapid changeovers between jobs. For studios and workshops focused on bespoke, high-value glasswork, the Glass Beveling Machine is more than a tool; it's the key to unlocking limitless design possibilities with uncompromised quality. Implementing the Glass Beveling Machine elevates a workshop's capabilities, allowing it to tackle prestigious commissions requiring the signature elegance only a perfect bevel can provide. The consistent brilliance delivered by the Glass Beveling Machine builds reputation and commands premium value in the marketplace.

Mastering the Mosaic Canvas: The Mosaic Glass Processing Machine

Where intricate patterns and vibrant artistry meet glass, our revolutionary Mosaic Glass Processing Machine takes center stage. This specialized solution addresses the unique challenges of assembling complex mosaic designs – a task traditionally dominated by slow, painstaking manual labor prone to errors and inconsistencies. The Mosaic Glass Processing Machine redefines efficiency and precision in this niche. Its core innovation lies in a high-precision, computer-controlled placement system combined with advanced vision recognition. Imagine feeding individual mosaic tiles – glass, ceramic, stone, or smalti – into the Mosaic Glass Processing Machine. Its vision system instantly identifies each tile's exact dimensions, color, and orientation. Guided by a digital template of the final design, robotic placement arms then position each tile onto a prepared backing mesh or sheet with micron-level accuracy at speeds unimaginable by hand. The Mosaic Glass Processing Machine handles intricate curves, detailed imagery, and complex color gradients flawlessly. Crucially, it maintains perfect, consistent grout spacing between every single tile, a critical factor for the structural integrity and aesthetic harmony of the finished mosaic panel. This capability is transformative for producing large-scale murals, intricate bathroom or kitchen surfaces, decorative pools, and public art installations. The mosaic glass processing machine significantly reduces production time, minimizes tile waste through precise placement, and eliminates the variations inherent in manual assembly. It empowers mosaic artists and manufacturers to scale their vision, tackle larger projects with confidence, and reproduce designs with absolute fidelity. For businesses specializing in decorative surfaces, the mosaic glass processing machine is not just an upgrade; it's a paradigm shift, turning intricate mosaic creation from a labor-intensive craft into a streamlined, high-precision industrial process. The speed and accuracy of the mosaic glass processing machine open new markets and creative horizons previously constrained by time and cost.

When high-volume production of perfectly beveled straight edges is paramount, the Glass Straight Line Beveling Machine stands as the undisputed champion. Engineered for demanding environments like architectural glazing, shower enclosure manufacturing, and furniture production, this machine delivers relentless speed and unwavering accuracy on linear bevels. The Glass Straight Line Beveling Machine excels at processing large volumes of rectangular or straight-edged glass panels, consistently applying identical bevel widths and angles with exceptional surface quality. Its robust design features heavy-duty conveyors, powerful grinding spindles optimized for beveling, and sophisticated edge tracking systems that ensure the bevel starts and finishes precisely where intended, panel after panel. The key to its productivity lies in simultaneous processing: the glass beveling machine often bevels multiple edges in a single pass or handles large batches with minimal operator intervention. Automated loading and unloading systems can be integrated, further boosting throughput. The true transformative power emerges when our Glass Beveling Machine, mosaic glass processing machine, Glass Straight Line Beveling Machine, and Glass Beveler operate within a coordinated workflow. Imagine a fabrication facility optimized for maximum flexibility and efficiency: Complex custom pieces with curved bevels flow seamlessly onto the Glass Beveling Machine, where its multi-axis capabilities create stunning, intricate edges. Simultaneously, large batches of shower door panels move efficiently through the Glass Straight Line Beveling Machine, achieving perfect, consistent bevels at high volume. In another area, a breathtaking mosaic mural for a luxury hotel lobby is being assembled with pixel-perfect precision by the mosaic glass processing machine. Meanwhile, smaller jobs, repairs, or specialized components requiring beveling are efficiently handled by the versatile Glass Beveler. This integrated approach eliminates bottlenecks. The Glass Beveling Machine handles the complex artistry, the Glass Straight Line Beveling Machine powers through the high-volume linear work, the Mosaic Glass Processing Machine masters intricate assemblies, and the Glass Beveler efficiently tackles the diverse smaller tasks. Workloads are intelligently routed based on specific requirements. Data flow between machines (where integrated) provides real-time insights into production status, material usage, and machine health.