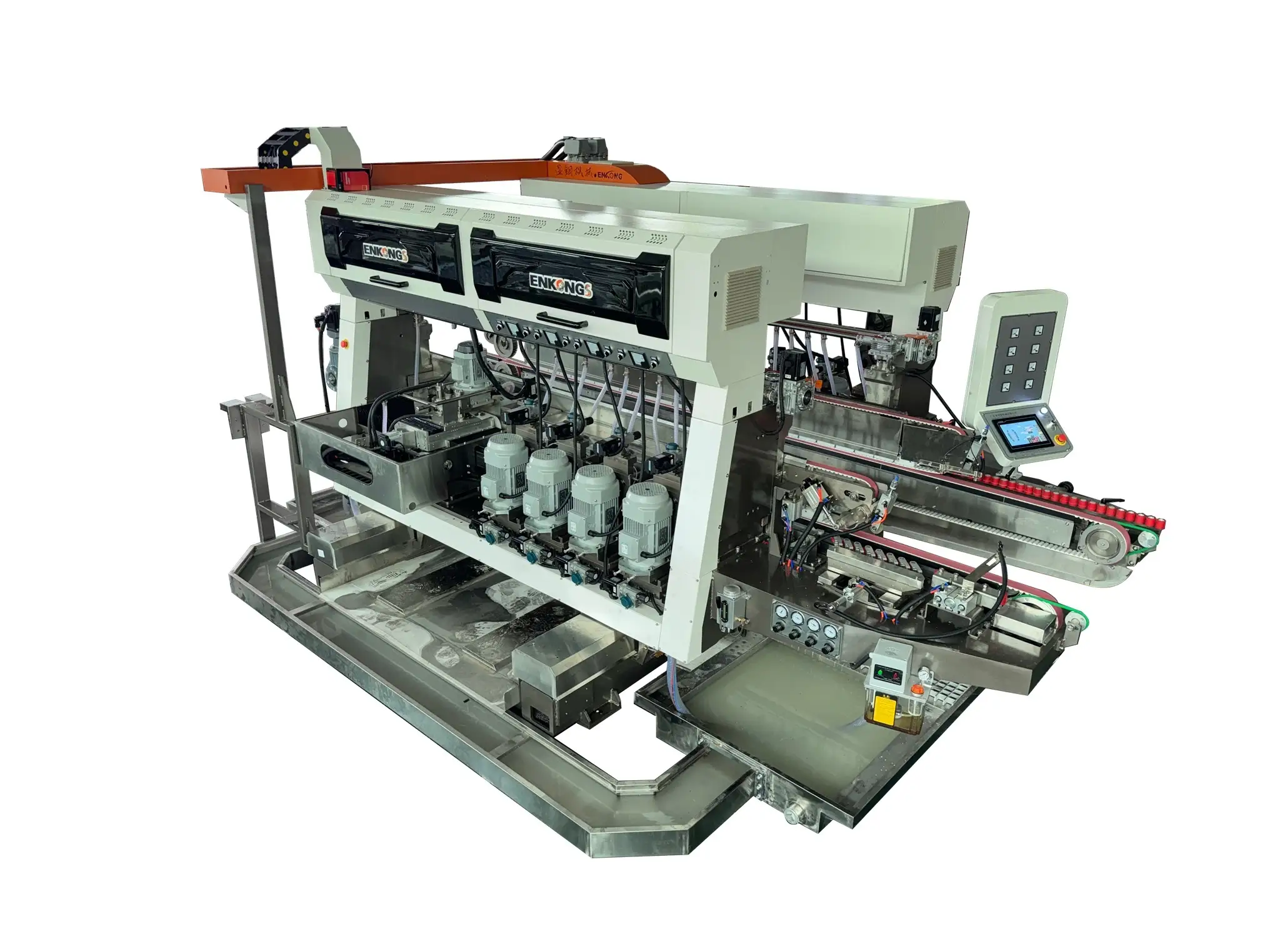

Product introduction of Enkongs glass bilateral machine series

As a well-known equipment manufacturer in the industry, Enkongs has created a high-end equipment matrix with Glass double edging machine as the core with profound technical research and development background and strict production and manufacturing standards, and deeply integrates Glass edg Ing machine, glass grinding machine and other key equipment provide integrated and intelligent solutions for glass processing in many fields such as construction, home furnishings, electronics and automobiles.

Enkongs Glass double edging machine is the benchmark of a series of products, and it is also the first choice equipment for bilateral synchronous fine processing of glass in the current market. This Glass grinding machine It adopts a symmetrical dual-station rigid body design, equipped with an imported high-precision servo drive system and linear guide rail, which can realize the whole process of bilateral synchronous feeding, synchronous rough grinding, synchronous finishing and synchronous polishing of glass, and the processing efficiency is more than twice that of traditional one-sided equipment. Enkongs Glass double edging machine is equipped with multiple sets of modular diamond grinding heads. The speed and feed of the grinding head can be intelligently adjusted. It can be adapted to flat glass of different thicknesses of 3-25mm. After processing, the edge of the glass has high verticality and uniform gloss. There are no edges, burrs and other defects, and it fully meets the processing standards of high-end products such as hollow glass, tempered glass and laminated glass. In addition, Enkongs Glass edging machine has a built-in intelligent size detection and thickness identification system, which can automatically match processing parameters, greatly reduce manual operation errors, ensure the stability and consistency of mass continuous production, and become a large-scale glass The core equipment of the processing production line.

As an important collaborative equipment of Glass double edging machine, Enkongs Glass edging machine has built a perfect product system, covering a variety of processing types such as straight edge, round edge, bevel edge, etc. Each Gla The ss edging machine continues the brand's high-rigidity and high-precision design genes. The fuselage adopts the overall casting technology of cast iron, and the operation process is stable and vibration-free, ensuring that the processing accuracy is always at the leading level in the industry. Enkongs Glass edging machine is equipped with a humanized touch operation interface, and the parameter settings are intuitive and convenient. Operators can quickly complete the processing switching of different specifications of glass, whether it is small-scale customized production or large-scale batch processing, Glass edg Ing machine can meet the differentiated needs of customers with excellent adaptability and reliability. At the same time, Enkongs Glass edging machine can be seamlessly connected with Glass double edging machine to form a more automated processing production line, realizing the whole process from glass loading to finished product unloading. Humanized operation helps enterprises reduce costs and increase efficiency.

In the fine processing of glass processing, Enkongs glass grinding machine plays an indispensable key role. This glass grinding machine is equipped with high wear-resistant diamond grinding wheels, with strong and stable grinding. Ability, the glass edge processed by Glass double edging machine and Glass edging machine can be refined for the second time, effectively eliminate fine scratches and processing residues, and further improve the smoothness of the glass edge and Texture. Enkongs glass grinding machine supports a variety of special modeling processing such as chamfers, rounded corners, duckbill edges, etc. to meet the personalized design needs of high-end glass products. Glass grinding machine has a built-in high-efficiency negative pressure dust removal system. It can collect glass chips and dust generated during the processing process in real time, which not only ensures the cleanliness of the workshop environment, but also avoids the impact of dust on the transmission parts and accuracy of the equipment, and greatly extends the service life of the equipment. Each Enkongs glass grinding machine has undergone multiple factory inspection processes to ensure the stable and reliable operation of the equipment and protect the production and processing of customers.

From the selection of core components to the assembly and commissioning of the whole machine, Enkongs has always adhered to strict quality control standards. The whole series of equipment has passed the international quality system certification and been exported to many countries and regions around the world, which has won the high recognition of the majority of customers. The brand also provides one-stop after-sales service covering installation and commissioning, technical training, fault repair and accessories supply to solve customers' worries.

Whether it is a large-scale glass processing enterprise that pursues high efficiency or a processing workshop that focuses on high-end customization, Enkongs Glass double edging machine series products can become glass with excellent performance, stable quality and intelligent operation mode. The right assistant of glass processing and production helps enterprises move forward steadily in the fierce market competition.