ZM10W Glass Straight Line Edging Machine is a edging tool used in the glass industry. It has the advantages of accurate and straightforward edging to ensure high -quality glass products. The machine is usually used to produce glass windows, doors and mirrors. tempered glass, laminated glass and bulletproof glass. With laminated glass machine s effective cutting ability, laminated glass machine is an ideal choice for large glass manufacturing companies. WhatsAPP+86 188 2308 1142 Email:emily@enkongs.net

The modern glass industry operates under increasingly stringent requirements for dimensional accuracy, edge integrity, and optical clarity, particularly for glass that undergoes the tempering process. Traditional machinery often struggles with the specific demands of processing glass both before and after tempering, leading to bottlenecks, consistency issues, and elevated production costs. Global Glass Technologies' innovative approach solves these challenges through specialized equipment that operates in perfect harmony. The foundational glass straight-line edging machine establishes perfect edge geometry before tempering, while the specially engineered tempered glass edging machine handles the challenging task of refining already-tempered glass, with both pathways culminating in the flawless surface achievement of the advanced glass polishing machine. This holistic methodology represents a significant leap forward in production line integration and quality assurance.

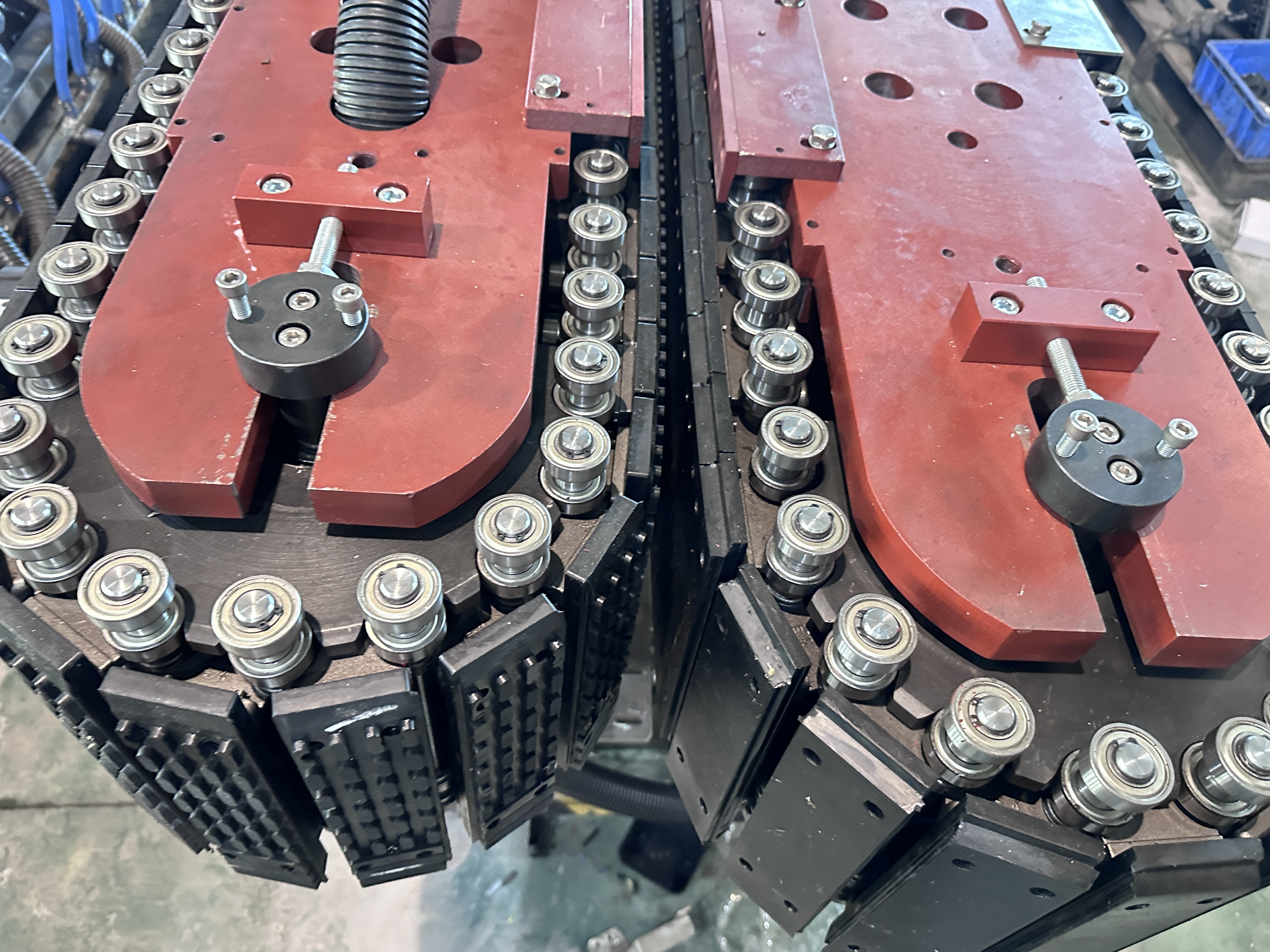

This engineering marvel represents the pinnacle of precision grinding technology for annealed glass, specifically designed to create perfectly straight, consistently angled edges on glass before it enters the tempering furnace. Equipped with diamond grinding heads of exceptional durability and CNC-controlled positioning systems, this glass straight-line edering machine processes glass from 3mm to 25mm thickness with astonishing accuracy and repeatability. It produces clean, chip-free edges with precise bevels, chamfers, and arrises that are essential for both structural integrity and aesthetic appeal. The quality of work performed by this glass straight-line edging machine directly impacts the efficiency of downstream processes; a perfectly edged piece from this machine requires minimal processing on either the tempered glass edging machine or the glass polishing machine, thereby optimizing the entire production workflow and reducing consumable costs across the operation. Working with tempered glass presents unique challenges due to its inherent tension and hardness, requiring specialized machinery that differs significantly from a standard glass straight-line edging machine. This robust tempered glass edging machine features reinforced structural components, higher horsepower spindles, and specialized diamond tools specifically formulated to cut through the hardened surface of tempered glass without causing micro-fractures or edge defects. Its advanced cooling systems prevent heat buildup that could compromise the glass's temper, while vibration-dampening technology ensures smooth, consistent operation. The tempered glass edging machine enables fabricators to make adjustments, create notches, or refine edges on already-tempered glass—a capability that significantly reduces rejection rates and allows for greater flexibility in fulfilling custom orders. The output from this tempered glass edging machine provides an optimal surface for final finishing on the glass polishing machine.

Advanced temperature and pressure monitoring systems ensure consistent results across all glass types and thicknesses. Whether receiving glass from the glass straight-line edging machine or the tempered glass edging machine, this glass polishing machine delivers edges of exceptional quality that are safe to touch and visually flawless, adding significant value to the finished product.The seamless interaction between these specialized systems creates remarkable production efficiencies and quality improvements. Glass destined for tempering typically follows a path through the glass straight-line edging machine for precise shaping before heat treatment, potentially bypassing the tempered glass edging machine entirely if no post-temper adjustments are needed, and proceeding directly to the glass polishing machine for final finishing. Conversely, glass that requires cutting or edge modification after tempering is routed through the specialized tempered glass edging machine, then to the glass polishing machine for refinement. This flexible routing, managed by an intelligent central control system, ensures that each glass panel receives the most efficient processing sequence based on its specific requirements, maximizing throughput while minimizing energy consumption and tooling wear. The glass polishing machine consistently delivers superior results when it receives properly prepared edges from either the glass straight-line edging machine or the tempered glass edging machine.

The introduction of this targeted technology suite—the precision-focused glass straight-line edging machine, the specialized tempered glass edging machine, and the perfection-driven glass polishing machine—represents a quantum leap forward for the global glass processing industry. It provides manufacturers with a clear path to enhanced capabilities, improved profitability, and stronger competitive positioning in increasingly demanding markets. By understanding the distinct yet complementary roles of each machine, glass processors can build optimized production workflows that deliver exceptional quality with unprecedented efficiency.