ENKONGS' straight line beveling machines equipped with advanced research and development technology, to ensure accurate and efficient glass grinding. With strong production capacity, glass process machine can handle large quantities of glass grinding tasks. It has reliable performance and high customer satisfaction.Would you be interested in learning more? WhatsAPP+86 188 2308 1142 Email:emily@enkongs.net

In the highly competitive glass fabrication industry, achieving flawless edges and precise bevels while ensuring high production efficiency has become a hallmark of successful manufacturers. Our company is proud to introduce three innovative machines that will revolutionize your production capabilities: the versatile glass edging machine, the intelligent glass processing machine, and the high-speed straight-line beveling machine. These machines create a comprehensive ecosystem that addresses every facet of modern glass fabrication—from initial processing to final edge perfection. This powerful combination of glass process machine offers unparalleled precision, efficiency, and quality control, empowering manufacturers to confidently undertake complex projects while maintaining profitability on high-volume orders.

At the heart of the production line sits the glass processing machine, a true multitasker that streamlines multiple fabrication steps into one efficient operation. This intelligent system combines cutting, drilling, and edge preparation in a single pass, significantly reducing handling time and minimizing the risk of damage between processes. The glass processing machine features advanced digital controls that allow operators to program complex cutting patterns and hole configurations with ease. Its precision drilling capability is particularly valuable for applications requiring exact hardware placement, such as shower doors, glass railings, and architectural panels. The machine's adaptive technology automatically adjusts cutting parameters based on glass thickness and type, ensuring optimal results across different materials. By consolidating multiple processing steps, the glass processing machine dramatically improves workflow efficiency while maintaining exceptional accuracy.

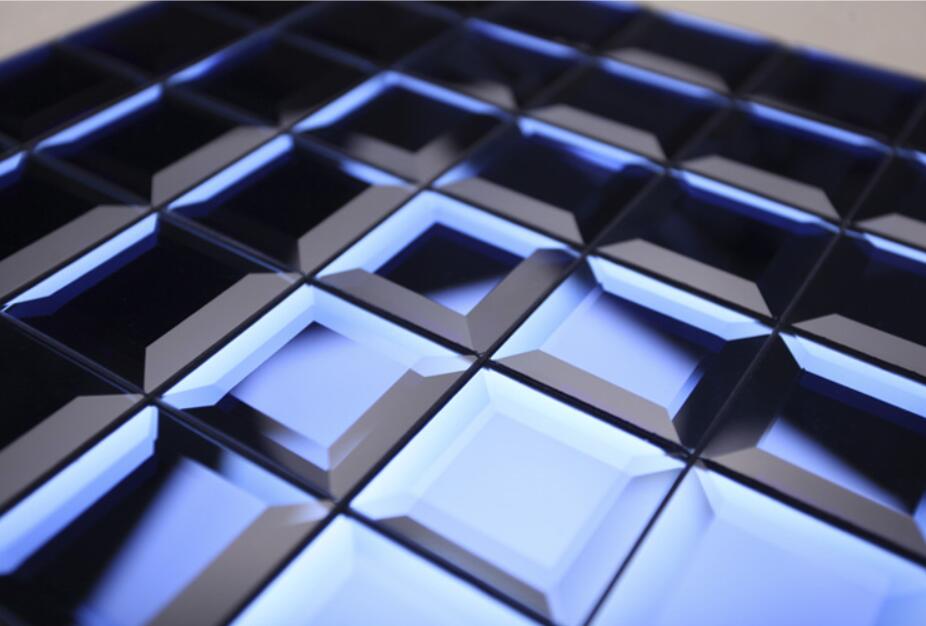

For operations specializing in high-volume production of beveled edges, the glass process machine delivers unmatched speed and consistency. This specialized equipment revolutionizes the production of decorative bevels on mirrors, tabletops, and architectural glass elements. The glass process machine can process multiple edges simultaneously, achieving perfect angle consistency across the entire length of each panel. Glass edging machine's advanced cooling system prevents overheating during extended production runs, while automatic wheel dressing maintains optimal cutting performance. The machine's precision tracking system ensures each bevel starts and stops exactly where intended, eliminating waste and rework. For businesses supplying the interior design and furniture markets, the glass edging machine provides a competitive edge by enabling fast turnaround of premium beveled products by the use of glass process machine.

The synergy between these three machines creates a production powerhouse that can handle virtually any glass fabrication challenge. The glass processing machine prepares the raw material with precision cuts and holes, the glass edging machine refines the edges to exact specifications, and the glass edging machine adds decorative bevels where required. This seamless workflow minimizes handling and reduces production time while ensuring consistent quality across all products. Manufacturers implementing this complete system report significant improvements in both productivity and product quality, along with reduced material waste and labor costs.

What truly sets these machines apart is their shared commitment to user-friendly operation and intelligent design. All three machines feature intuitive touchscreen interfaces that reduce training time and minimize operator errors. Advanced diagnostic systems monitor machine performance in real time, alerting technicians to potential issues before they cause downtime. The glass edging machine, glass processing machine, and glass process machine are all designed for easy maintenance, with accessible components and straightforward service procedures. These common design philosophies ensure a smooth learning curve for operators moving between different machines in the production line.

The glass edging machine, glass processing machine, and glass process machine represent the culmination of years of research and development in glass fabrication technology. By combining advanced engineering with practical, user-focused design, we've created a system that addresses the real-world challenges faced by today's glass manufacturers. Whether you're a small shop looking to expand your capabilities or a large producer seeking to optimize your workflow, this trio of machines provides the tools you need to compete in an increasingly demanding market. The precision of the glass edging machine, the versatility of the glass processing machine, and the speed of the glass edging machine work in harmony to deliver results that were previously unattainable.

In conclusion, the combination of the glass edging machine, glass processing machine, and glass process machine creates a complete solution for modern glass fabrication. This powerful trio of glass process machine delivers the precision, efficiency, and versatility needed to excel in today's competitive market. By investing in these machines, manufacturers gain not just equipment but a strategic advantage that can transform their business.