ZM9J Glass Variable Miter Machine is suitable for mitering glass from a 0 - 60 degree angle. The glass mitering machine is designed to coarse/fine grinding and polishing flat glass. Big pitch chain gear is adopted for conveying which makes a stable conveying and high precision process.9 grinding head motors each gets its own oil lubricating circuit which makes no rusting and smooth working and long service live. Push the button, the 5 motors as one unit swaying frame to swing from 0-60degree. WhatsAPP+86 188 2308 1140 Email:jmek@enkongs.net

The glass processing industry is undergoing a significant transformation, propelled by advancements in core glass processing equipment. At the heart of this evolution lies the enhanced performance of modern glass straight-line edging machines, which serve as pivotal tools for shaping and refining flat glass. These machines have evolved beyond mere grinders; they now embody a synthesis of precision engineering and digital control, establishing new benchmarks for efficiency and quality. The integration of advanced glass processing equipment has redefined the capabilities of these edging machines, enabling faster cycle times and more intricate edge profiles. This progress directly influences the productivity within the glass grinding machine sector, as a precisely edged piece of glass typically requires less intensive downstream finishing processes. The synergy among various types of glass processing equipment is essential for creating a seamless workflow that spans from initial cutting to the final polished edge delivered by high-performance straight-line edging machines.

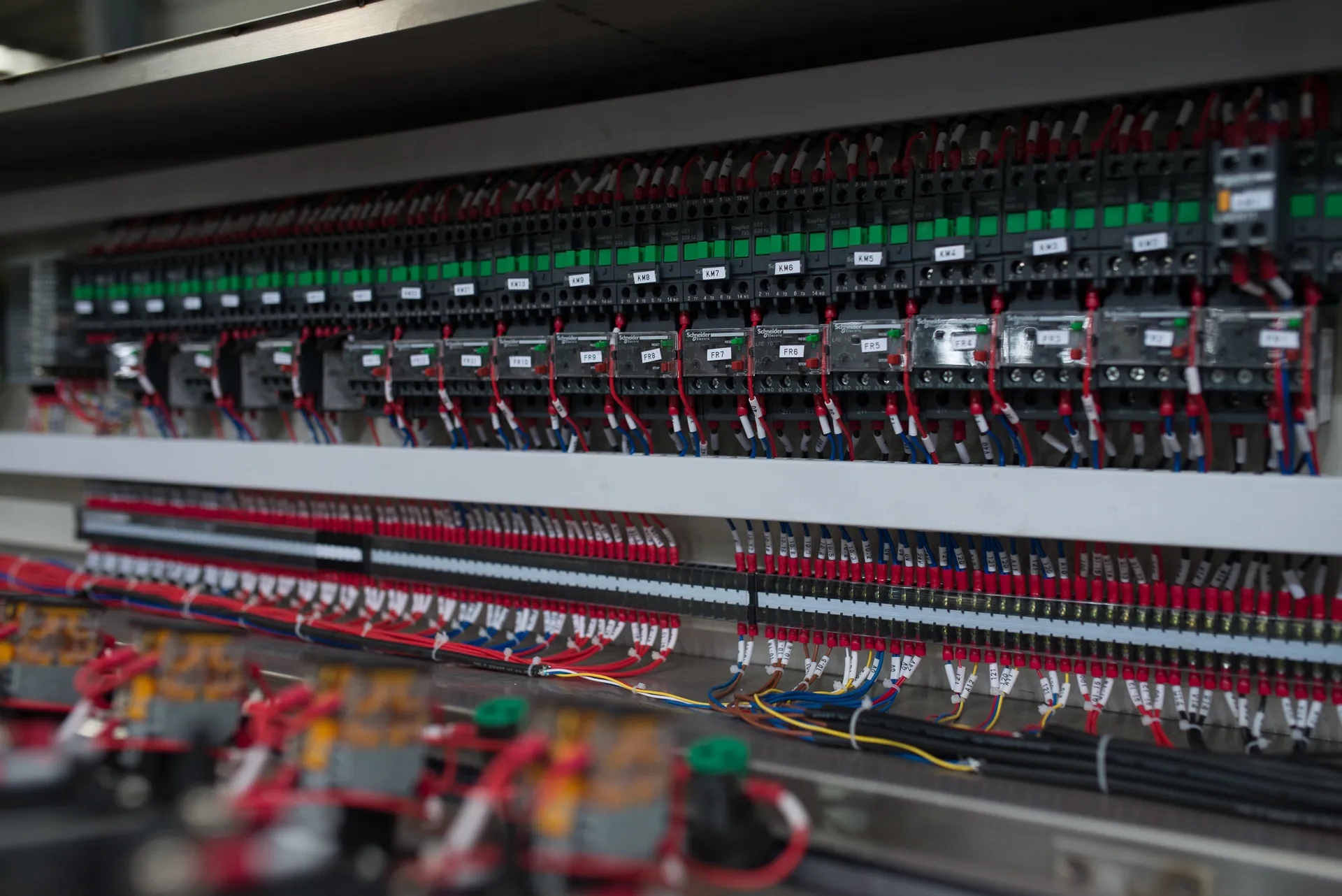

A key driver behind this advancement is the sophistication inherent in contemporary models of glass grinding machines. Modern iterations are equipped with programmable logic controllers and touch-screen interfaces, allowing operators to input precise parameters for each job. This level of control is crucial for ensuring that a glass straight-line edging machine can execute consistent and repeatable bevels, miters, and flat polishes across diverse types of glass—from standard float varieties to ultra-hard tempered options. The fundamental mechanism within any glass grinding machine consists of multiple spindles fitted with diamond-impregnated grinding wheels, each designated to perform specific tasks ranging from roughing to fine polishing. When applied to a straight-line edging machine, this technology yields an unparalleled edge quality that meets the stringent demands associated with architectural, automotive, and furniture applications.

The role of a dedicated glass grinding machine extends beyond the linear processing capabilities offered by a glass straight-line edging machine. While the latter excels in handling the peripheral edges of rectangular or square panels, a versatile glass grinding machine is typically designed for more specialized tasks, including shaping, drilling, and intricate edge work. Nevertheless, the fundamental principles of material removal remain consistent across this category of glass processing equipment. The advancement of more durable diamond tools and efficient coolant systems has significantly benefited both general-purpose glass grinding machines and specialized glass straight-line edging machines. These innovations mitigate wear and tear on the machinery itself—a critical factor for ensuring the long-term viability of all glass processing equipment. Continuous improvements in abrasive technology guarantee that every glass grinding machine operates at peak efficiency, delivering superior finishes with minimal chipping.

When considering the acquisition of new glass processing equipment, manufacturers must meticulously evaluate the specific function of a glass straight-line edging machine within their production line. This machine often serves as the cornerstone for high-volume edge work; its selection directly influences the requirements for subsequent stations involving glass grinding machines. Key factors such as processing speed, number of grinding heads, and level of automation are paramount considerations. A judiciously selected glass straight-line edging machine can substantially reduce manual labor associated with edge finishing, thereby enhancing overall throughput. The interoperability among various pieces of glass processing equipment underscores the industry's shift towards integrated manufacturing solutions. Consequently, investing in a robust glass straight-line edging machine is not merely an upgrade; it represents a strategic decision aimed at optimizing the entire ecosystem of glass processing equipment on the factory floor.

Looking ahead, the future of glass processing equipment is intrinsically linked to advancements in automation and data intelligence. The next generation of glass straight-line edging machines is expected to incorporate enhanced IoT capabilities, enabling real-time monitoring of production metrics and predictive maintenance requirements. Similarly, a smart glass grinding machine may autonomously adjust its grinding parameters based on the thickness and hardness of the glass, thereby optimizing the process without human intervention. This interconnected network of glass processing equipment will foster a more responsive and efficient manufacturing environment. The evolution of the glass straight-line edging machine from a standalone unit to an integrated component within a smart factory highlights the dynamic nature of this industry. Continuous innovation in glass grinding technology ensures that it remains an essential element in advanced material fabrication.

In conclusion, the ongoing refinement of glass processing equipment is crucial for the growth of the glass manufacturing sector. The glass straight-line edging machine emerges as a pivotal innovation, providing precision and speed for linear edge work. Its development is complemented by the versatile and enduring capabilities of the glass grinding machine, which addresses a wider range of finishing tasks. Together, these machines constitute the backbone of modern glass fabrication. As technology advances, we can anticipate that these indispensable pieces of equipment will become even more efficient and intelligent, solidifying their role in producing high-quality glass products that define contemporary architectural and design landscapes. The journey from raw sheet to finished product for every piece of glass is profoundly influenced by both the capabilities of the glass straight-line edging machine and those offered by its complementary counterpart—the glass grinding machine.