1.Product Description

1. XM351A https://www.enkongmachinery.com/glass-straight-line-beveling-machine-xm351a Glass Straight-line Beveling Machines are used for grinding bevel and bottom edge of glass with different size and thickness. Rough grinding, fine grinding, polishing of bevel and grinding of bottom edge can be completed in one time. It is easy to adjust the feeding of motor in the all and the one and beveling angle while glass thickness is being changed. Same thickness of glass sheet can be process continually. The brightness of finished surface will be almost the same as glass itself.

Glass beveling machines are essential tools in the glass manufacturing industry, providing a means to create precise, decorative, and functional edges on glass products. The introduction of automated beveling machines has revolutionized the glass processing sector, offering manufacturers increased efficiency, accuracy, and versatility in their production processes. This paper aims to explore the role and benefits of glass beveling machines for manufacturers, highlighting how these machines contribute to the enhancement of glass products and the overall productivity of manufacturing operations.

2.It is easy to adjust the feeding of motor in the all and the one and beveling angle while glass thickness is being changed. Same thickness of glass sheet can be process continually. The brightness of finished surface will be almost the same as glass itself.

3.(Independent wool felt wheel + the cerium oxide ) make the flat edge more shining.

4.Input and output conveyor adopt timing belt which can improve the transmission precision.

5.Rear beam can be adjusted up and down which is suitable for processing small pieces of glass.

6.The electrical elements with famous ABB/ Schneider brand.

7.All mechanical feeding parts with lubricating system.

8. Glass Straight-line Beveling Machine is also used to process mosaic glass, inlay glass, spell mirror glass and craft glass ect.

9.XM351 https://www.enkongmachinery.com/glass-straight-line-beveling-machine-xm351can grind out the bevel angle of 3-30°arrises (5 rough and fine grinding + 3 polishing + 1 round bottom edge); XM351A can grind out the bevel angle of 3-45°arrises glass.

10.XM351Acan be raised and adjusted, and the later maintenance will be more convenient. The minimum processing size of XM351Ahttps://www.enkongmachinery.com/glass-straight-line-beveling-machine-xm351a is 30*30mm. The minimum processing size of XM351 is 120*120mm.

11.The processing speed is adjustable with variator which offers a wide range of speed selection.

12.ENKONGS was set up in 2004, one of the famous manufacturers of glass equipment.We has our own CNC center to processing all machanical parts for our glass machine. Quality control in the house.

13.ENKONGS accepts reasonable custom-made.

14.

Glass beveling machines are sophisticated pieces of equipment that have become indispensable in the modern glass manufacturing industry. These machines are designed to create beveled edges on glass, which are not only aesthetically pleasing but also serve functional purposes such as reducing the risk of injury from sharp edges and enhancing the structural integrity of glass products. The evolution of glass beveling technology from manual processes to highly automated machines has significantly impacted the efficiency, precision, and capabilities of glass manufacturers worldwide.

The primary function of a glass beveling machine is to shape the edges of glass panels at various angles, producing a sloped edge that is both visually appealing and safer to handle. These machines utilize abrasive wheels that grind away the glass at precise angles and depths, resulting in a uniform bevel that meets the specifications required for the intended application. The process can be applied to a wide range of glass thicknesses and types, from simple window panes to complex architectural glass designs.

The advantages of incorporating glass beveling machines into manufacturing operations are manifold. Firstly, these machines significantly increase production efficiency by automating a labor-intensive task that would otherwise require skilled artisans to perform manually. This automation not only speeds up the production process but also ensures a higher degree of consistency and accuracy in the finished product. Furthermore, the ability to customize bevel designs and dimensions allows manufacturers to cater to a diverse range of customer requirements, from standard bevels to intricate, bespoke patterns.

In addition to these operational benefits, glass beveling machines also contribute to the cost-effectiveness of manufacturing processes. By reducing the need for manual labor and minimizing material waste through precise cutting, manufacturers can achieve a better return on investment over time. The safety enhancements provided by beveled edges also contribute to a reduction in workplace accidents, which can result in lower insurance costs and a more favorable safety record.

As the glass industry continues to evolve, incorporating advanced technologies such as Computer Numerical Control (CNC) and integration with CAD/CAM software, glass beveling machines are becoming even more sophisticated. These advancements enable manufacturers to produce complex designs with ease, further expanding the potential applications of beveled glass in various sectors, including architecture, automotive, furniture, and consumer electronics.

In conclusion, the role of glass beveling machines in the manufacturing industry cannot be overstated. They offer a multitude of advantages that enhance productivity, improve product quality, and open up new possibilities for innovation in glass design. As manufacturers continue to seek ways to improve their competitive edge, investing in advanced glass beveling technology will undoubtedly play a crucial role in their success.

2. Parameter

Type | XM351 | XM351A |

Spindles QTY | 9PCS | 9PCS |

Min. Glass size | 120*120mm | 30*30mm |

Processing glass thickness | 3-19mm | 3-19mm |

processing speed | 0.8-4.1m/min | 0.8-4.1m/min |

Weight | 3800 KGS | 4250kg |

Installation power(kw) | 19.08kw | 22.83kw |

Occupied size(mm) | 7700*1400*2500mm | 7800*1400*2500mm |

Arris | 30° | 45° |

Bevel width | 40mm | 40mm |

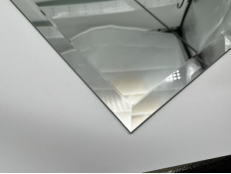

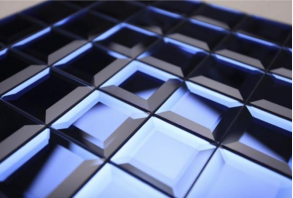

3.Glass sample

XM351 https://www.enkongmachinery.com/glass-straight-line-beveling-machine-xm351

XM351A

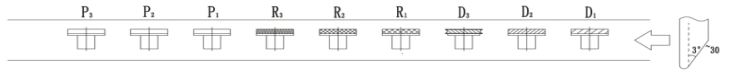

4.Wheels arrangement

XM351

XM351A

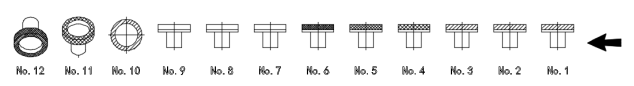

XM351 Wheel arrangement

NO. |

Wheels |

Specification |

Function |

NO.1 | Flat edge diamond wheel | Φ150*Φ12*100mesh |

Rough beveling |

NO.2 | Flat edge diamond wheel | Φ150*Φ12*180mesh | |

NO.3 | Round edge diamond wheel | Φ175*Φ22*R5*180mesh | bottom grinding (pencil edge) |

NO.4 |

Resin wheel |

Φ150*12*20*13 3# 170mesh |

Bevel grinding |

NO.5 | Resin wheel | Φ150*12*20*13 5# 325mesh | |

NO.6 |

Resin wheel |

Φ150*12*20*13 5# 325mesh | |

NO.7 | Wool felt | Φ150*Φ105*35 |

Bevel polishing |

NO.8 |

Wool felt | Φ150*Φ105*35 | |

NO.9 |

Wool felt

|

Φ150*Φ105*35

|

XM351A Wheel arrangement

NO. |

Wheels |

Specification |

Function |

NO.1 | Beveling diamond wheel | Φ150*Φ12*100mesh |

Rough beveling |

NO.2 | Beveling diamond wheel | Φ150*Φ12 *180mesh | |

NO.3 | Round edge diamond wheel | Φ175*Φ22*R5*180mesh |

bottom grinding (pencil edge) |

NO.4 | Resin whee | Φ150*12*20*13 240mesh |

Bevel grinding |

NO.5 | Resin wheel | Φ150*12*20*13 325mesh | |

NO.6 | Resin wheel | Φ150*12*20*13 600mesh | |

NO.7 | Wool felt wheel | Φ150*Φ105*35 |

Bevel polishing |

NO.8 | Wool felt wheel | Φ150*Φ105*35 | |

NO.9 | Wool felt wheel | Φ150*Φ105*35 |

5.The processing center for processing mechanical parts

The construction and maintenance of industrial machinery are critical to ensuring longevity and reliability in various applications, from construction to manufacturing. One of the key processes that contribute to the robustness and durability of such machinery is the secondary heat treatment of critical components. This process is particularly important for the front and rear reinforced casting girders, columns, and bases, which are integral to the structural integrity of heavy machinery. By subjecting these components to secondary heat treatment, we can induce qualitative changes that significantly enhance their performance characteristics.

Secondary heat treatment, also known as post-weld heat treatment (PWHT), is a process applied to metal components after they have been welded. The primary goal of this treatment is to relieve residual stresses that develop during the welding process. These stresses, if left unaddressed, can lead to a host of problems, including cracking, distortion, and a reduction in the overall mechanical properties of the metal. By carefully controlling the temperature and cooling rate during the heat treatment process, we can improve the hardness, ductility, and toughness of the welded parts.

The process begins with heating the components to a specific temperature, which is maintained for a predetermined amount of time. This temperature is critical, as it must be high enough to alter the microstructure of the metal without causing it to lose its desired properties. The most common types of heat treatment used for welded structures include stress relieving, normalizing, and tempering. Stress relieving involves heating the metal to a suitable temperature below its critical range and holding it there for a specific period before allowing it to cool slowly. Normalizing improves the mechanical properties of the metal by refining its grain structure, while tempering reduces hardness and increases toughness in steel that has been hardened.

After the heat treatment process, the components undergo a transformation that makes them more durable and better suited to withstand the rigors of their intended use. The hardness of the metal is significantly improved, which is crucial for components that are subjected to high levels of stress and wear. Hardened components are less prone to deformation and can maintain their shape and function over an extended period, even under heavy loads.

In addition to the secondary heat treatment, the precision of the machinery is further enhanced by the use of spare parts that are processed by a CNC gantry machining center. Computer Numerical Control (CNC) machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools. These tools remove material from the workpiece to achieve the desired shape and size with a high degree of accuracy.

The CNC gantry machining center is particularly adept at handling large and heavy workpieces, which is often the case with the spare parts of industrial machinery. The gantry design allows for a wide range of motion and the ability to apply significant force, which is necessary for machining tough materials. The precision of the CNC machining process is unparalleled, as it can control the movement of the cutting tools to within a few thousandths of an inch.

One of the significant advantages of CNC machining is the reduction of cumulative tolerance in the assembly process. Tolerance refers to the allowable variation in the dimensions of a part. In traditional machining methods, the accumulation of small errors can lead to significant discrepancies in the final assembly. However, with CNC machining, the precision of each individual part is so high that the overall tolerance of the assembly is greatly reduced. This ensures that all components fit together perfectly, which is essential for the smooth operation of complex machinery.

Moreover, the edge grinding precision of the spare parts is also improved through CNC machining. Edge grinding is a finishing process that removes burrs and sharp edges from a part, creating a smooth and safe surface. The precision of the CNC gantry machining center allows for a consistent and high-quality edge finish, which not only enhances the aesthetic appeal of the machinery but also prevents potential damage to the machinery or injury to the operators.

In conclusion, the combination of secondary heat treatment and CNC gantry machining center processing for spare parts is a powerful approach to enhancing the durability and precision of industrial machinery. The secondary heat treatment strengthens the hardness of critical components, making them more resistant to wear and tear, while the CNC machining process ensures that spare parts fit together seamlessly, reducing tolerance and improving edge grinding precision. Together, these processes contribute to the creation of machinery that is not only more durable but also more precise, reliable, and efficient in its operation.

6. The edging assemble worksh

7.  The close-up photos and description of edger

The close-up photos and description of edger

|

|

| |

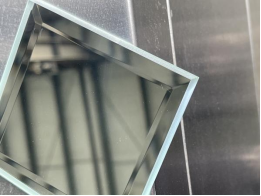

The lathe of edger, after grinding, milling ,drilling ,painting . the beams of edgers

Adopt reinforcement design to prevent beam deformation | |||

|

| ||

The front and rear chain plates adopt double chains plus suspension structure, the

clamping force is constant,easy to load and unload. | |||

| | ||

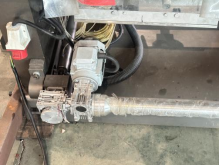

Swing Angle motor, you can adjust the glass angle you want and it is very convenient; The processing speed controlled by Stepless motor, But it can be upgrade as Frequency conversion | |||