Glass is an essential material used in various industries, including construction, automotive, and consumer electronics. The quality of glass edges is crucial for both aesthetic appeal and functionality. Uniformity in glass edges ensures that the glass fits perfectly into frames, reduces the risk of injury, and provides a smooth finish. Automatic glass machines, particularly Glass Edging Machines and Glass Edge Grinding Machines, play a vital role in achieving this uniformity. This article will explore how these glass processing machines ensure uniformity in glass edges, focusing on their design, functionality, and benefits.

1. The Role of Automatic Glass Machines in Glass Processing

Automatic glass machines are designed to streamline the glass processing workflow, reducing manual labor and increasing efficiency. These machines are equipped with advanced technology that ensures precision and uniformity in glass edges. The following are some of the key components of automatic glass machines:

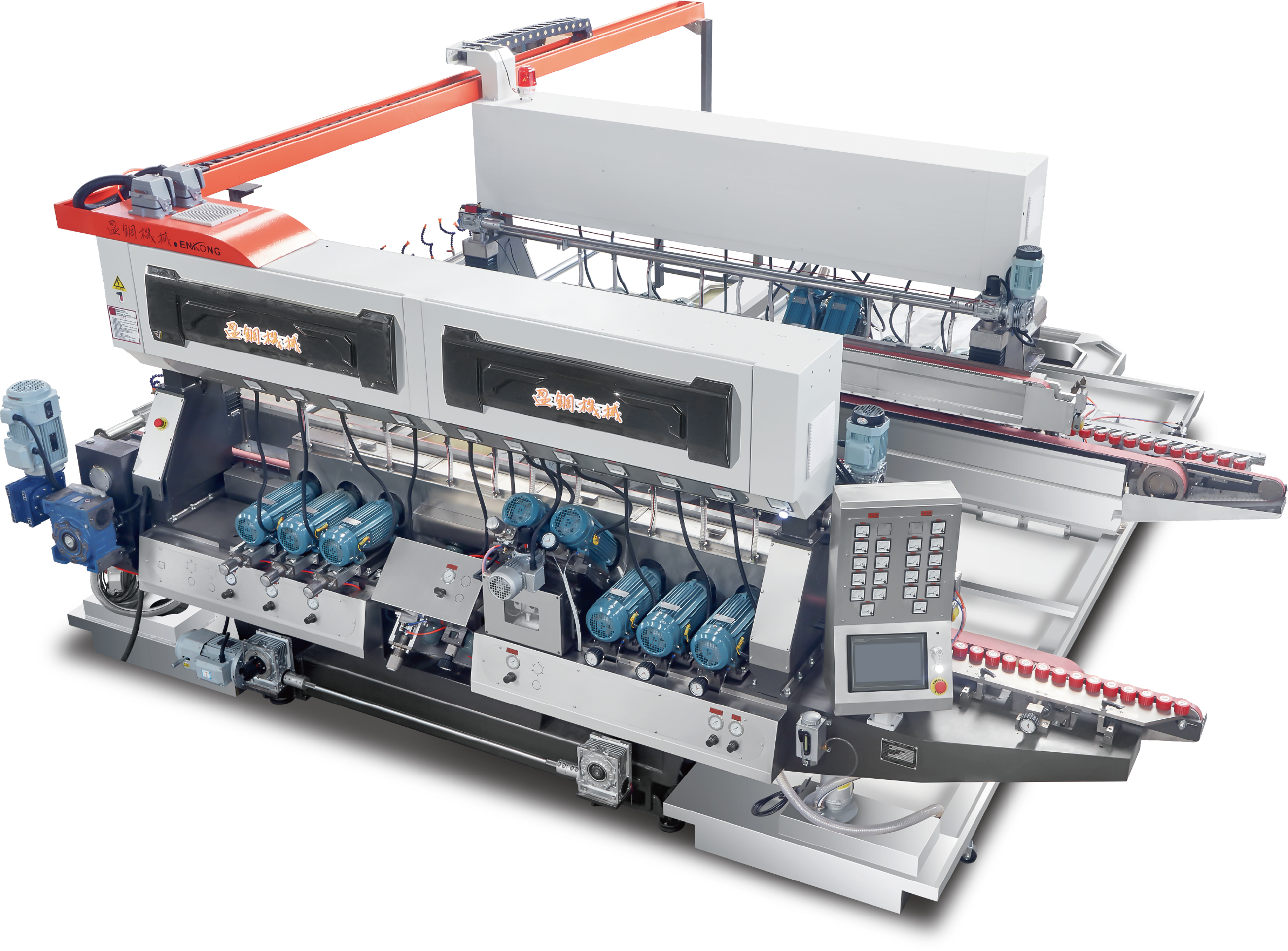

- Glass Edging Machines: These machines are specifically designed to shape and finish the edges of glass sheets. They can be used for both straight and curved edges, providing a smooth, uniform finish.

- Glass Edge Grinding Machines: These machines are used to grind and polish the edges of glass sheets, ensuring a smooth and precise finish.

- Glass Processing Machines: These machines encompass a wide range of equipment used in glass manufacturing, including cutting, edging, and polishing machines. 2. How Glass Equipment Ensure Uniformity

2. How Glass Equipment Ensure Uniformity

2.1. Design and Functionality

Glass Edging Machines are designed with precision and efficiency in mind. The following are some of the key features that contribute to their ability to ensure uniformity in glass edges:

- Multiple spindles: Glass Equipment typically have multiple spindles that work simultaneously to shape and finish the edges of glass sheets. This ensures that the edges are uniform and consistent across the entire sheet.

- Advanced control systems: These machines are equipped with advanced control systems that allow for precise adjustments in speed, feed rate, and pressure. This ensures that the glass edges are processed uniformly, regardless of the size or shape of the glass sheet.

- High-quality diamond tools: Glass Edging Machines use high-quality diamond tools to shape and finish the edges of glass sheets. These tools are designed to maintain their sharpness and durability, ensuring consistent and uniform results.

2.2. Process Flow

The process flow of Glass Edging Machines typically involves the following steps:

- Loading: The glass sheet is loaded onto the machine, and the machine's control system automatically adjusts the position and orientation of the glass for processing.

- Edge shaping: The multiple spindles work simultaneously to shape the edges of the glass sheet, ensuring uniformity and consistency.

- Edge finishing: The machine then polishes the edges, removing any roughness or imperfections and providing a smooth, uniform finish.

- Unloading: Once the edges are processed, the glass sheet is automatically unloaded from the machine, ready for further processing or assembly.

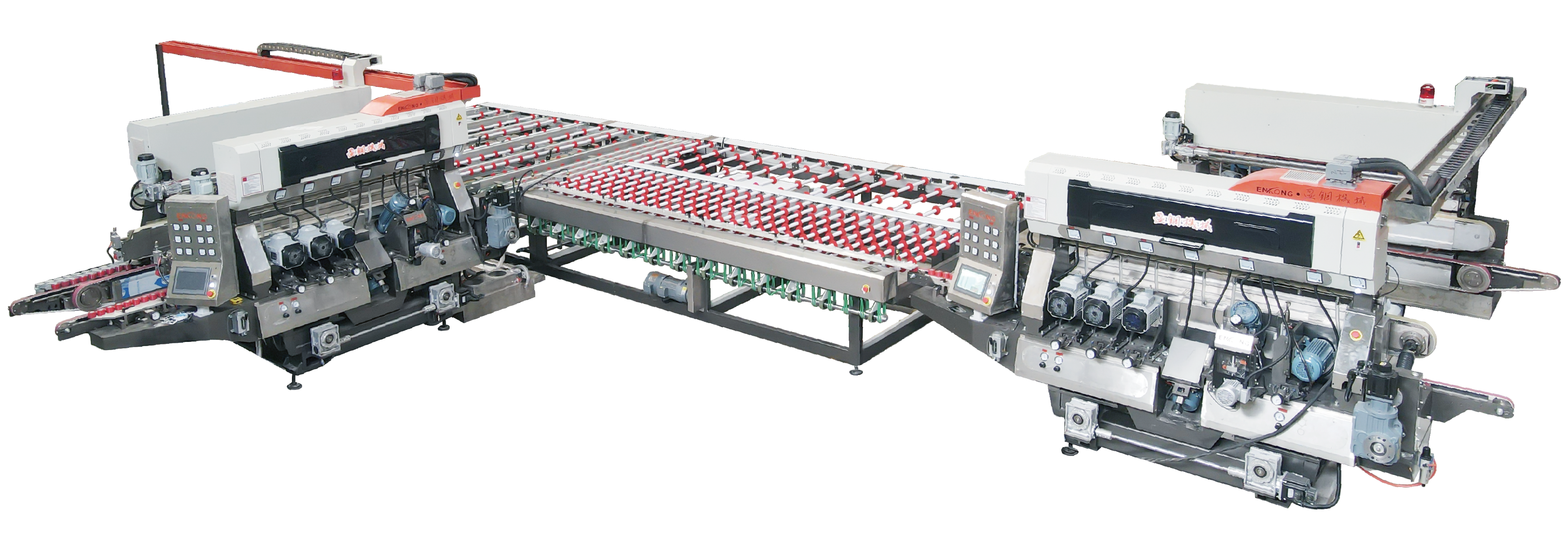

3. The Role of Glass Edge Grinding Machines

Glass Edge Grinding Machines are another essential component of the glass processing workflow. These machines are designed to grind and polish the edges of glass sheets, ensuring a smooth and precise finish. The following are some of the key features of Glass Edge Grinding Machines:

- Precision grinding wheels: These machines use precision grinding wheels to grind the edges of glass sheets, ensuring a uniform and precise finish.

- Variable speed control: Glass Edge Grinding Machines offer variable speed control, allowing for adjustments based on the specific requirements of the glass sheet being processed.

- Automatic feeding systems: These machines are equipped with automatic feeding systems that ensure consistent and uniform grinding of the glass edges.

4. Benefits of Using Automatic Glass Machines

The use of Automatic Glass Machines, including Glass Edging Machines and Glass Edge Grinding Machines, offers several benefits:

- Increased efficiency: These machines significantly reduce the time and effort required to process glass edges, increasing overall efficiency in the glass manufacturing process.

- Improved quality: The precision and uniformity provided by these machines result in higher quality glass products, reducing the risk of defects and customer complaints.

- Enhanced safety: Automatic glass machines minimize the need for manual handling of glass sheets, reducing the risk of injury to workers.

- Cost savings: By streamlining the glass processing workflow and reducing manual labor, these machines can help businesses save on labor costs and increase profitability.

Glass Edging Machines and Glass Edge Grinding Machines are essential tools in the glass processing industry, ensuring uniformity and precision in glass edges. These automatic glass machines not only improve the quality of glass products but also increase efficiency and reduce costs. As technology continues to advance, we can expect even more sophisticated glass processing machines that will further enhance the quality and uniformity of glass edges.