How Can Glass Edge Polishing Machines Improve the Aesthetics of Glass Products

In this era of technology and innovation, glass products have permeated every aspect of our lives. From home decoration to construction, from electronic products to transportation, the use of glass materials has undoubtedly brought aesthetically pleasing visual effects to various fields. However, to unleash higher aesthetic value in glass products, a high-quality glass edge polishing machine is indispensable.

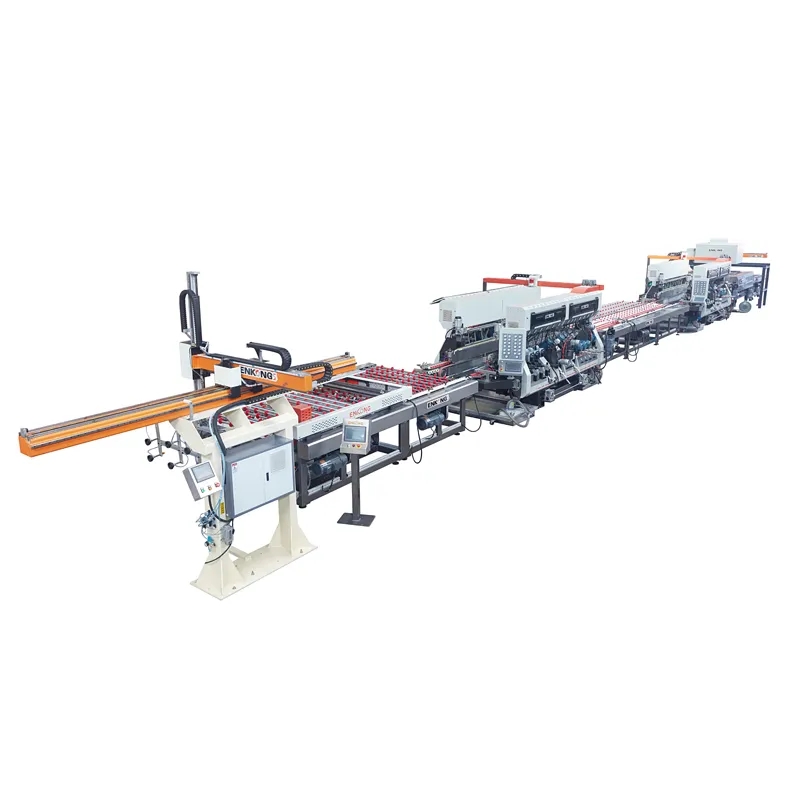

Glass edge polishing machine, as the name suggests, is a device used to process the edges of glass. It processes glass edges with precision grinding, chamfering, and polishing by means of a high-speed rotating grinding wheel, making the edges of glass products smoother and more beautiful. So how does a glass edge polisher enhance the aesthetic value of glass products?

Firstly, the glass edge polishing machine can achieve precise processing of glass products. Thanks to advanced numerical control systems and high-precision transmission devices, the glass edge polishing machine can achieve precise control of the edges of glass products, ensuring consistency in processing dimensions and shapes. In today's pursuit of individualization and customization, precise processing capabilities enable glass products to meet various design needs and provide unlimited possibilities for designers' creativity.

Secondly, the glass edge polisher enriches the surface treatment effects of glass products. Through different edge grinding, chamfering, polishing and other processing techniques on glass, glass products present a rich and diverse texture. Whether it is a smooth and bright edge or a clearly defined three-dimensional edge, a glass edge grinding machine can easily achieve it. These unique surface treatment effects add a unique aesthetic value to glass products, allowing them to stand out among competitors.

Moreover, glass edge grinding machines improve production efficiency. Compared with traditional manual edge grinding processes, glass edge grinding machines use automated production lines, greatly improving production efficiency. This means that the aesthetic upgrade of glass products is no longer limited by human power and time, and can meet market demand faster, creating more value for enterprises.

Finally, glass edge grinding machines contribute to environmental protection. By precise processing and rich surface treatment effects, glass edge grinding machines make glass products more attractive, reducing glass waste. At the same time, the application of automated production lines reduces labor costs, further reducing energy consumption in the production process. While enhancing the aesthetic value of glass products, glass edge grinding machines also help enterprises achieve green production.

In summary, glass edge grinding machines play a crucial role in enhancing the aesthetic value of glass products. A high-quality glass edge polisher, such as ENKONGS from China, with its outstanding performance and rich processing capabilities, helps glass products achieve aesthetic upgrades and add a touch of creativity to your designs.

Here, we sincerely invite glass product manufacturers, designers, and friends to work together with ENKONGS' glass edge polishers to explore new horizons in glass aesthetics. Let the glass edge polisher give your products a unique charm and lead the glass industry towards a brighter future!

Glass edge polisher specifications:

1. Machine structure: High-strength cast iron bed, superior stability and resistance to deformation;

2. CNC system: International well-known brand CNC system, precise control of the processing process;

3. Drive system: High-precision belt drive to ensure stable processing speed;

4. Number of grinding heads: Multi-grinding head design, can achieve multi-step processing with one loading;

5. Processing range: Can meet the processing needs of various thickness and size glass products;

6. Surface treatment effect: Can achieve bright edge, dark edge, and three-dimensional edge surface effects;

7. Production efficiency: Automated production line, high efficiency and energy saving, improve production efficiency;

8. Safety performance: The entire machine is equipped with multiple safety protection devices to ensure the safety of operators.

Conclusion:

Glass edge polisher makes glass product aesthetic upgrades within reach. Join us with our high-quality glass edge polishers and create a better future together!