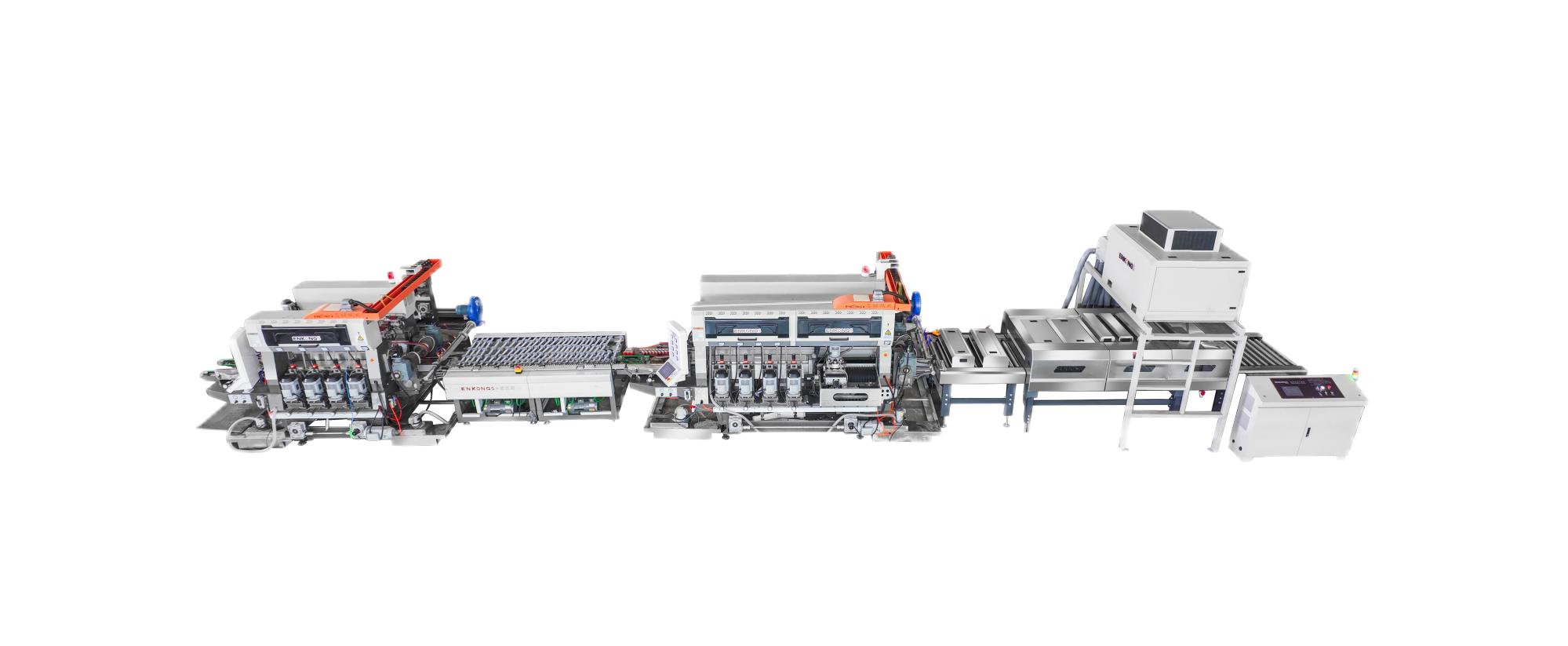

Enkongs SYM08-Double Pencil Edging Machine: The speed of the whole line is 1-15m / min ( sure depending on the edging margin). The Glass Double Edging Machine full line adopts the PLC control system to set the processing parameters through the human-machine interactive interface to complete the processing at one time.

In today's industrial landscape where precision, automation, and adaptability are paramount, our company proudly unveils a transformative suite of glass processing solutions designed to dominate global manufacturing. We present our state-of-the-art Automatic Glass Machine, the versatile Home Appliance Glass Machine, and the robust Glass Double Edging Machine. This powerful trio represents the pinnacle of engineering innovation, meticulously crafted to address escalating demands across diverse sectors – from high-volume appliance production to bespoke architectural fabrication. These integrated ecosystems streamline workflows, slash production costs, enhance quality, and unlock unprecedented operational efficiency. This strategic launch underscores our commitment to pushing technological boundaries and empowering clients in an intensely competitive marketplace.

The relentless demand for thinner, stronger, and more complex glass components necessitates equipment that eliminates traditional bottlenecks of slow cycle times, inconsistent quality, labor dependency, and material waste. Our engineering team responded with this synergistic trio: the Glass Double Edging Machine for seamless, intelligent processing; the highly adaptable Home Appliance Glass Machine configured for nuanced appliance component needs; and the precision-focused Glass Double Edging Machine handling intricate shapes. Each machine incorporates advanced automation, sophisticated sensor technology, and intelligent software control, ensuring flawless, consistent results batch after batch. The Automatic Glass Machine forms the intelligent core, while the Home Appliance Glass Machine and Glass Double Edging Machine provide specialized capabilities, creating a comprehensive manufacturing solution.

The Intelligent Production Core: The Automatic Glass Machine

At the heart of modern glass fabrication stands the Glass Double Edging Machine, an embodiment of intelligent, self-optimizing production. This system transcends mere speed, integrating comprehensive automation that minimizes human intervention while maximizing uptime and consistency. Imagine a production cell where glass panels are intelligently loaded, oriented, processed, quality-checked, and unloaded with minimal operator oversight. The Automatic Glass Machine achieves this through an integrated ecosystem featuring robotic arms with advanced vision-guided positioning, real-process monitoring sensors, and adaptive control algorithms. Its core innovation lies in predictive operation – the machine learns from each cycle, optimizing feed rates, tool pressure, and coolant flow for varying glass types and thicknesses. The Automatic Glass Machine continuously analyzes spindle vibration, motor load, and edge quality data, making micro-adjustments to maintain perfection.

The operational impact is transformative. Facilities deploying the Automatic Glass Machine report 30-60% reductions in direct labor costs and near-elimination of human-error defects. Its "lights-out" manufacturing capability allows extended unmanned production shifts, dramatically increasing asset utilization. The Automatic Glass Machine integrates seamlessly with factory MES/ERP systems, providing real-time production data, predictive maintenance alerts, and automatic job scheduling. Crucially, this intelligence ensures resource efficiency. The Automatic Glass Machine precisely calculates optimal cutting paths, minimizes grinding wheel wear through adaptive pressure control, and reduces coolant consumption via targeted application systems. For manufacturers transitioning towards Industry 4.0, the Automatic Glass Machine is the indispensable foundation.

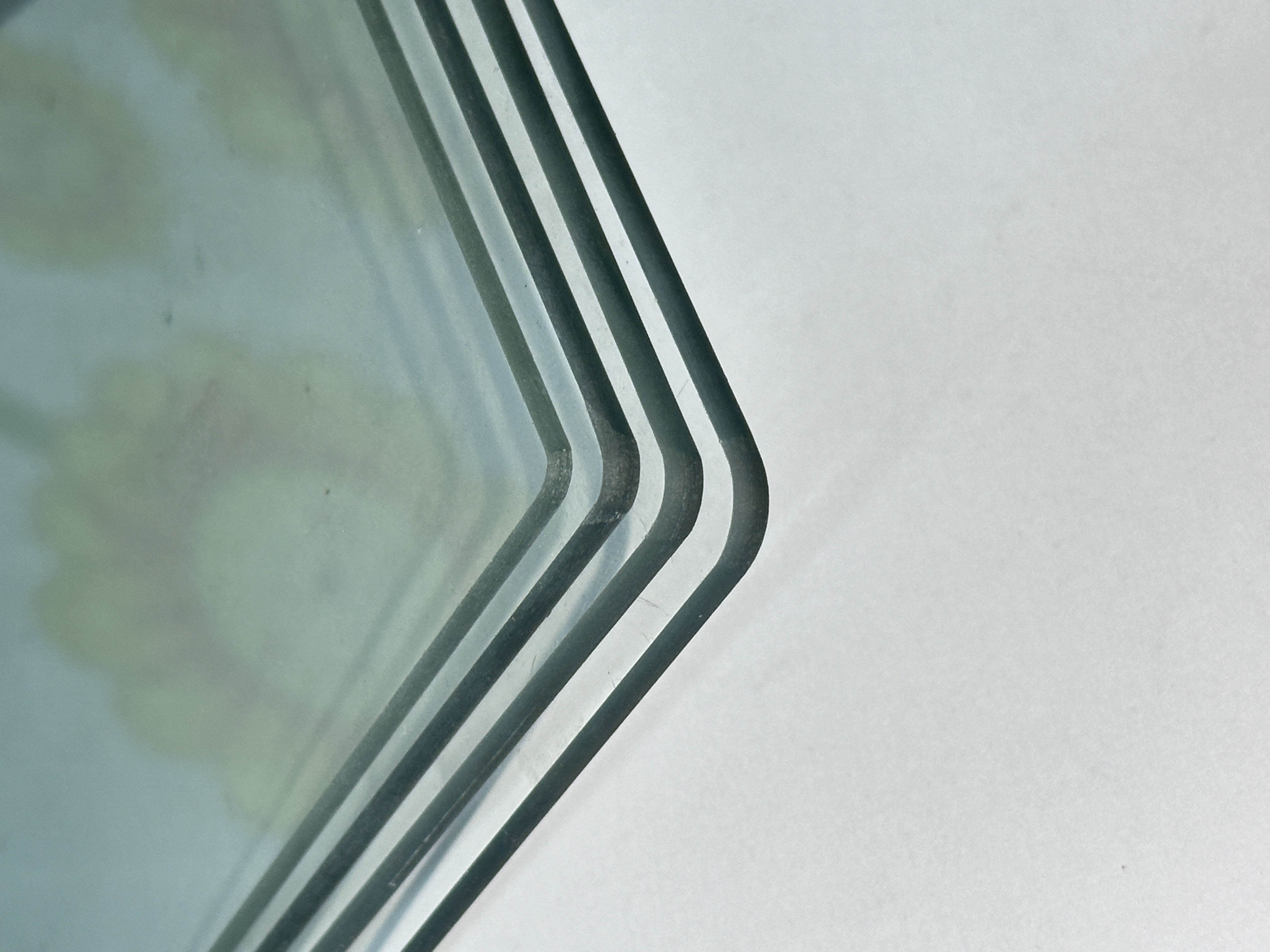

While automation provides the foundation, the appliance industry demands specialized capabilities. This is where our dedicated Home Appliance Glass Machine excels. Appliance glass encompasses diverse requirements: oven doors needing thermal resilience, refrigerator shelves requiring load-bearing precision, cooktops demanding flawless aesthetics, and intricate control panels with complex cutouts. Generic automation struggles with this diversity. The Home Appliance Glass Machine is engineered as the ultimate flexible specialist. Its core strength is an advanced 7-axis CNC platform offering unparalleled freedom, enabling straight-line edging, intricate profiling, precision hole drilling, sophisticated shaping, and decorative engraving within a single setup. This multi-functionality drastically reduces handling and cycle times while improving accuracy.

The Home Appliance Glass Machine integrates intelligence specifically for appliance standards. Advanced vision systems ensure perfect alignment of cutouts and edge profiles relative to printed patterns. Material handling adapts to diverse appliance glass – from thin control panels to thick tempered oven doors. Crucially, the Glass Double Edging Machine incorporates databases for appliance-specific edge finishes (seamed, polished, arrised) required for safety and aesthetics. Its software features libraries of common profiles and cutouts, enabling rapid changeovers essential for multi-model production. Real-time sensors monitor grinding pressure, coolant flow, and tool wear, ensuring unwavering quality across complex batches. The Home Appliance Glass Machine is the specialized partner appliance manufacturers require, enabling faster innovation, reduced complex-part scrap rates, and maintained brand quality. Its adaptability supports seamless scaling from prototyping to mass production. The Home Appliance Glass Machine complements the Automatic Glass Machine by adding industry-specific intelligence, while both leverage the precision of the Glass Double Edging Machine for superior edge quality.