GUANGDONG ENKONGS MACHINERY CO., LTD & JIANGMEN ENKONGS INTELLIGENT TECHNOLOGY CO LTD (KNOWN AS ENKONG) we are specializing in the research and development and production of edging equipment. the production workshop is located in jiangmen city, guangdong province. there are more than 100 employees. the workshop covers an area of 10,000 square meters.

Enkongs products have been widely used in glass (construction, solar, industrial glass), sintered stone, ceramic tiles industries and the enkongs product have been highly recognized by customers.

machining precision processing. focus on each details.the machining accuracy is 0.01mm.

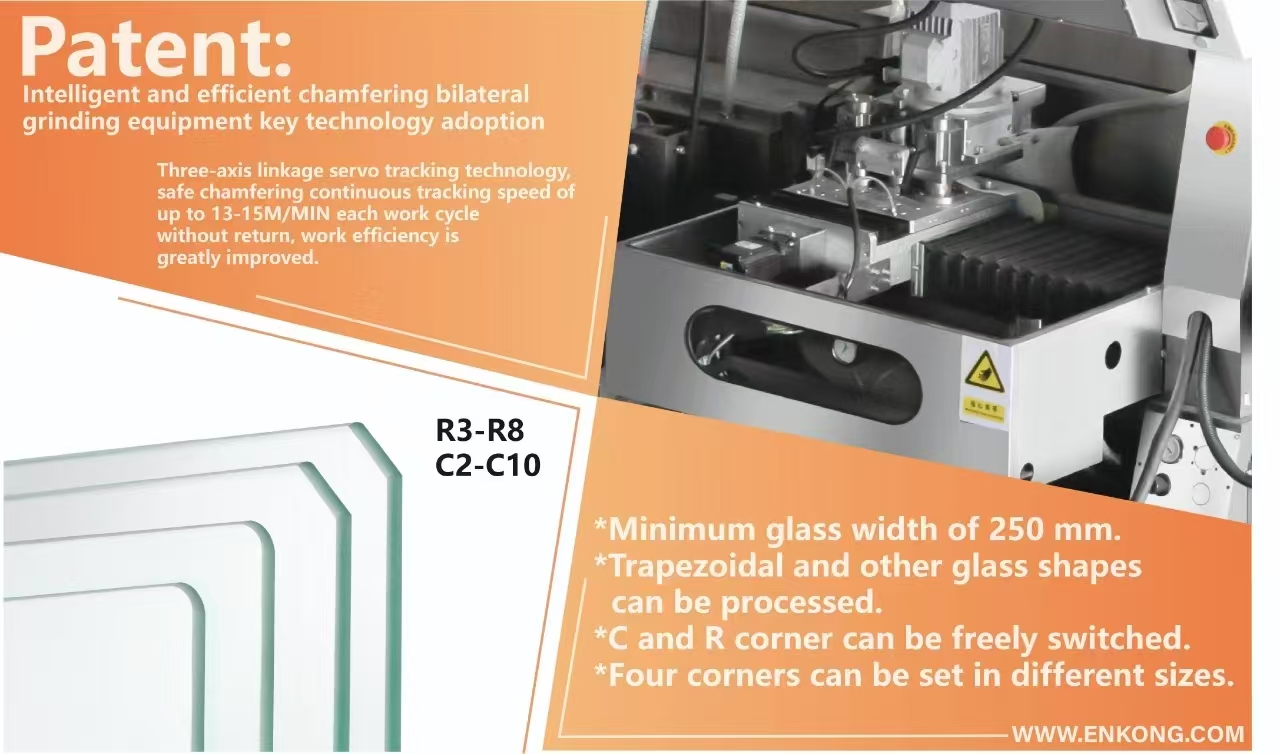

As global demand for precision glass products rises—spanning architecture, home appliances, and consumer electronics—manufacturers are under increasing pressure to deliver higher productivity, greater accuracy, and superior surface finishes. In response, our company has introduced a comprehensive solution portfolio centered around the most advanced high-speed double edging machine, a refined home appliance glass machine series, and a robust line of glass double edging machines engineered for 24/7 industrial performance.Our latest offerings reflect years of R&C and field testing to meet the rapidly evolving needs of glass fabricators. With market-leading features and smart automation integration, these machines ensure quality, consistency, and operational efficiency.

The glass processing industry is experiencing transformative growth. Customers expect thinner, stronger, and more precisely finished glass across all product categories. This is especially true for sectors such as home appliances, where glass aesthetics and durability are critical.

Traditional systems are no longer sufficient. To remain competitive, manufacturers are turning toward innovations like the high-speed double edging machine, which drastically cuts cycle times while improving accuracy. In tandem, the home appliance glass machine continues to gain importance due to its ability to process decorative and tempered glass panels for ovens, refrigerators, and smart kitchen appliances.

Flagship Product: glass double edging machine

Integrated glass polishing station with zero-defect assurance

Whether used for large architectural panels or smaller consumer-grade pieces, the high-speed double edging machine consistently delivers fine edge quality at throughputs exceeding 25 meters per minute.

Home Appliance Glass Machine: Specialty Processing with Precision.

Glass used in home appliances demands a unique combination of style and structural integrity. Our latest home appliance glass machine addresses these specific requirements with multiple inline functions including: Edge grinding, Corner cutting, Surface polishing, Hole drilling and Tempering-ready outputs.

The modular design ensures flexible configuration, whether for microwave panels, gas stove glass tops, or refrigerator doors. With plug-and-play automation and minimal maintenance, our home appliance glass machine has quickly become the preferred choice for OEMs and tier-one suppliers.

Expanding the Glass Double Edging Machine Lineup

In response to customer demand for versatile solutions, our range of glass double edging machine models now includes multiple sizes and control levels: Compact models for low-volume operations, fully automatic CNC-controlled versions for high-capacity lines and dual-head machines with polishing and chamfering modules.All glass double edging machines in our lineup are compatible with smart manufacturing systems and can be integrated with ERP/MES platforms for centralized quality tracking.

Integrated Systems and Smart Manufacturing

One of the key differentiators in our current product range is the seamless integration of AI-driven diagnostics and performance tracking. Every high-speed double edging machine, home appliance glass machine, and glass double edging machine is equipped with predictive maintenance alerts, production efficiency dashboards and remote troubleshooting access.

In an era where precision, speed, and adaptability are non-negotiable in industrial manufacturing, our company proudly unveils a transformative suite of glass processing solutions designed to dominate the market. We present our state-of-the-art High-Speed Double Edging Machine, the versatile Home Appliance Glass Machine, and the robust Glass Double Edging Machine. This powerful trio represents the pinnacle of engineering innovation, meticulously crafted to address the escalating demands of diverse sectors, from high-volume appliance production to bespoke architectural glass fabrication. These machines aren't just tools; they are integrated ecosystems engineered to streamline workflows, slash production costs, enhance product quality, and unlock unprecedented levels of operational efficiency for manufacturers worldwide. This strategic launch underscores our unwavering commitment to pushing the boundaries of glass processing technology and empowering our clients to thrive in an intensely competitive global landscape.

At the heart of our productivity revolution stands the High-Speed Double Edging Machine. Engineered for manufacturers prioritizing sheer output without sacrificing an iota of quality, this machine redefines the meaning of rapid processing. Imagine a production line where glass panels flow continuously, their edges ground, polished, or beveled to perfection at speeds previously considered unattainable. The High-Speed Double Edging Machine achieves precisely this. Its core innovation lies in a radically optimized material handling system featuring ultra-responsive servo drives, high-capacity conveyor belts designed for minimal slippage, and precision-guided linear motion components. This allows glass sheets to be loaded, processed, and unloaded in a seamless, uninterrupted flow. The cutting and grinding spindles of glass double edging machine themselves are masterpieces of high-velocity engineering. Utilizing premium bearings, optimized coolant delivery systems that prevent thermal distortion even at maximum RPM, and advanced spindle designs that minimize vibration, the High-Speed Double Edging Machine operates at rotational speeds significantly higher than conventional counterparts.