ENKONGS' ZM10W Glass straight line edging machines are essential equipment in the glass processing industry, providing precision and efficiency in shaping and polishing glass edges. These Glass Edging Equipment play a crucial role in ensuring the quality and aesthetics of glass products, making them indispensable tools for glass manufacturers.

In today’s hyper-competitive architectural, interior design, and luxury manufacturing sectors, flawless glass finishing isn’t a luxury—it’s the defining edge. Recognizing the relentless demand for perfection, our company proudly unveils a transformative trio engineered to dominate global production floors: the versatile glass edging machine, the optically superb glass polish machine, and the lightning-fast high speed glass edger. This powerhouse combination represents a quantum leap in glass fabrication technology, meticulously designed to vaporize bottlenecks, eliminate waste, and deliver breathtaking quality at unprecedented speeds.

When curves, angles, and unique shapes define a project’s elegance, the glass edging machine emerges as the indispensable artist. The glass edging machine achieves this through advanced multi-axis CNC control, guiding grinding and polishing spindles along complex paths with unwavering accuracy. Operators can effortlessly program diverse edge profiles: safe seamed finishes, elegant pencil rounds, light-catching bevels, or custom decorative shapes.

Advanced slurry management continuously delivers the perfect polishing medium, while powerful extraction instantly removes waste particles, preventing secondary scratches. Crucially, integrated sensors scan surface roughness in real-time. The glass polish machine automatically adjusts pressure, speed, and dwell time to achieve the target Ra (surface roughness average) value uniformly across the entire panel—regardless of size or thickness. Facilities using the glass polish machine report near-zero surface defect rejections and a dramatic elevation in product perceived value. It enables fabricators to command premium prices for glass renowned for its pristine clarity. Beyond beauty, a perfectly polished surface from the glass polish machine resists staining and simplifies cleaning—critical for high-traffic architectural and hospitality settings. Its automation reduces reliance on rare manual polishing skills, guaranteeing consistent perfection shift after shift.

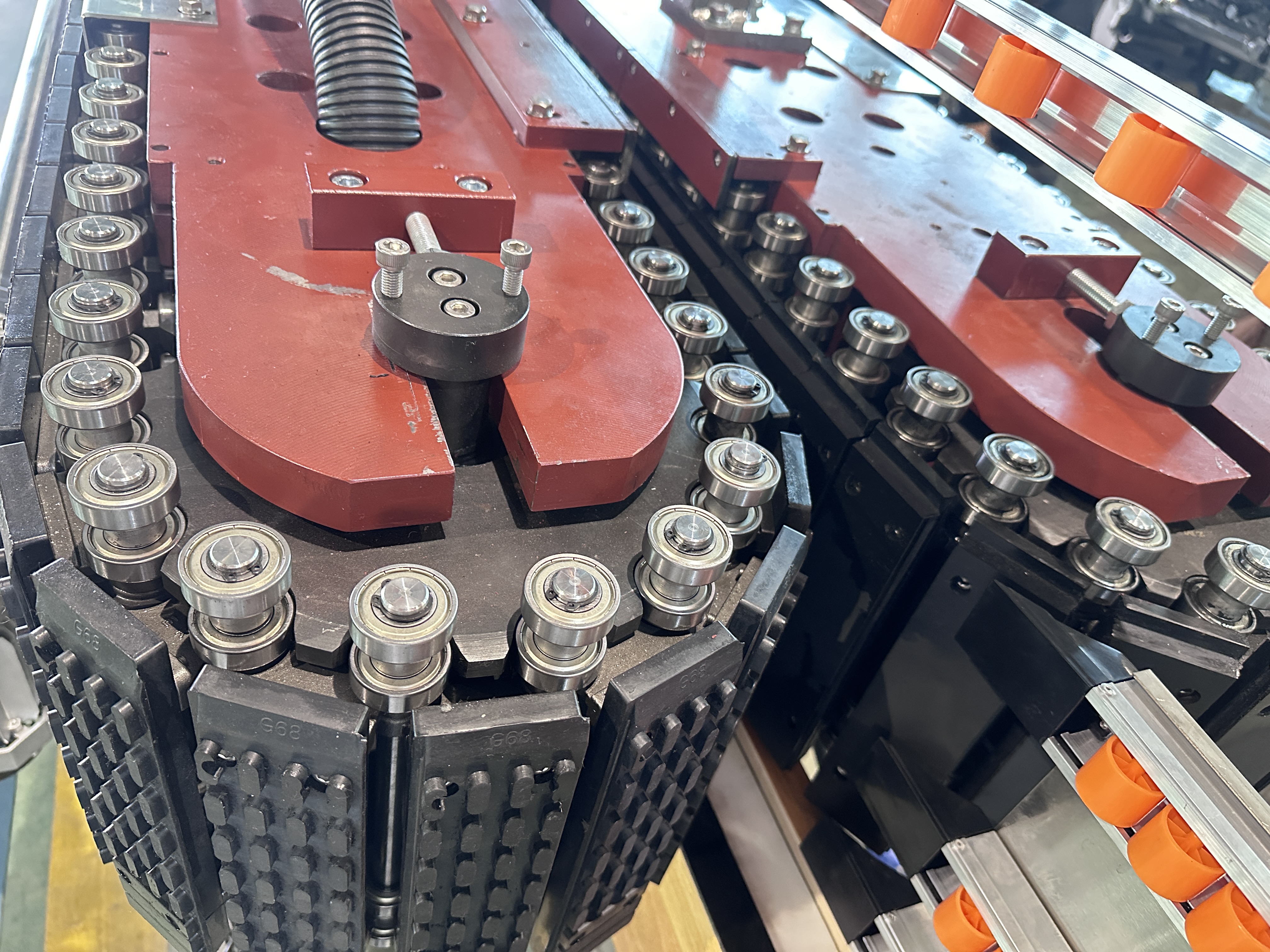

The impact is staggering. Production lines using the high speed glass edger report throughput increases of 40-70% versus older equipment. This directly slashes unit costs, accelerates order fulfillment, and enables confident capture of large-volume contracts. The machine’s inherent stability at high speeds ensures exceptional edge consistency—thousands of identical panels meet exact tolerances and finish requirements. Robust construction minimizes downtime, while predictive maintenance alerts prevent costly stoppages. Options for automatic loading/unloading further amplify efficiency. For businesses focused on scaling standardized rectangular components, the high speed glass edger isn’t just an upgrade; it’s a strategic imperative. Its relentless efficiency frees floor space and labor for value-added tasks like complex assembly or rigorous quality control. Witnessing the high speed glass edger operate is witnessing the future of mass glass production—a symphony of speed, precision, and unwavering reliability.

The true competitive revolution ignites when the glass edging machine, glass polish machine, and high speed glass edger operate within an intelligent, connected workflow. Imagine a seamless production ecosystem: Complex curved or shaped components flow to the versatile glass edging machine for contour-perfect edge finishing. Panels requiring optical perfection—luxury tabletops, high-definition display glass—are routed to the glass polish machine for surface transformation. Meanwhile, vast quantities of straight-edged architectural panels or shower screens race through the high speed glass edger, achieving flawless edges at breathtaking volume. This intelligent routing, orchestrated by a central Manufacturing Execution System (MES), ensures every piece uses the optimal machine for its requirements. This integration vaporizes bottlenecks and maximizes asset utilization. Workloads dynamically balance based on real-time capacity. Data streams from all three machines—monitoring the contour precision of the glass edging machine, the surface scanning of the glass polish machine, and the edge tracking/speed metrics of the high speed glass edger.

Energy Efficiency: High-efficiency motors, regenerative drives (capturing braking energy on the high speed glass edger’s conveyors), and smart power management slash energy consumption by up to 30%, reducing operational costs and carbon footprint.

Water & Resource Stewardship: Closed-loop coolant filtration systems recycle >90% of water and coolant, capturing glass sludge from the glass edging machine and high speed glass edger, and polishing residues from the glass polish machine and glass edging machine.

Waste Minimization: Precision engineering directly reduces glass waste. The accuracy of the glass edging machine prevents breakage on curves. The consistent finish of the glass polish machine eliminates surface rejects. The edge tracking of the high speed glass edger avoids misgrinding. Less raw material becomes costly cullet.

Longevity means Sustainability: Decades-long lifespans reduce the environmental burden of manufacturing replacements. Choosing these machines signifies a commitment to both world-leading productivity and responsible resource stewardship.