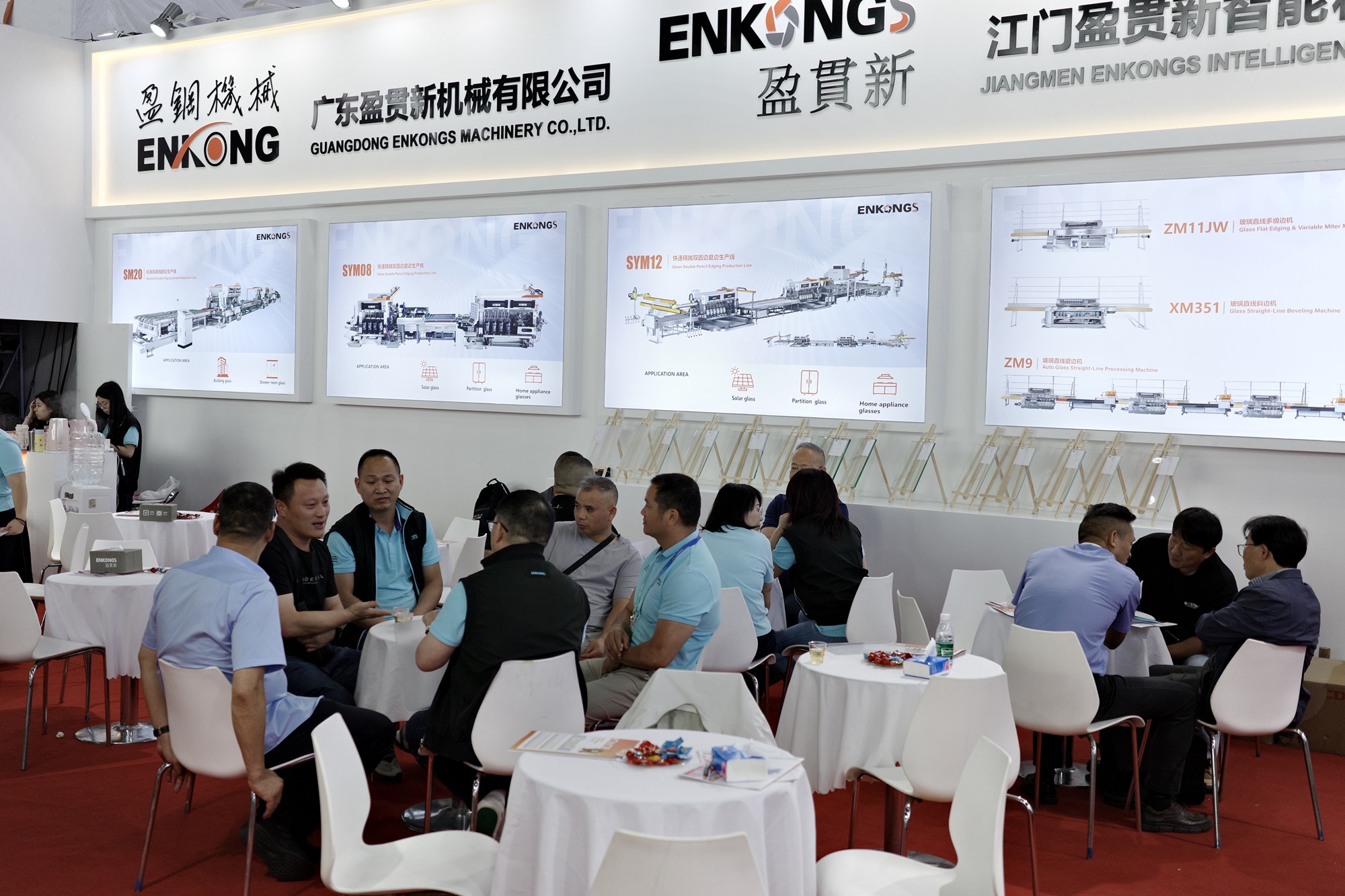

The roar of polishing diamonds and hum of automation filled W1-161 as Enkongs unveiled its revolutionary glass edging machine series at China International Glass Industrial Technical Exhibition 2025. Against a backdrop of China's accelerating glass industry transformation – where Shahe's deep-processing rate now exceeds 40% and green manufacturing mandates reshape production – Enkongs' intelligent glass grinding machines emerged as the exhibition's undisputed game-changers.

1. Industry Evolution Demands Smarter Glass Processing Machines

China's architectural, automotive, and photovoltaic sectors now require unprecedented precision. Traditional glass grinding machines falter with next-generation materials:

Ultra-thin electronic glass (≤0.7mm)

Textured solar panels with anti-reflective coatings

Curved automotive glazing with ±0.15mm tolerance requirements

"Five years ago, we processed three edge types; today we handle seventeen," observed Enkongs' Chief Engineer Wang Lei during his technical briefing. This complexity demands glass processing machines that combine flexibility with uncompromising accuracy – precisely what drew crowds to Enkongs' 360m² demonstration zone where their signature glass edging machine processed architectural panels at 1.8 meters/minute.

2. SM24 Series: The Glass Edging Machine Revolution

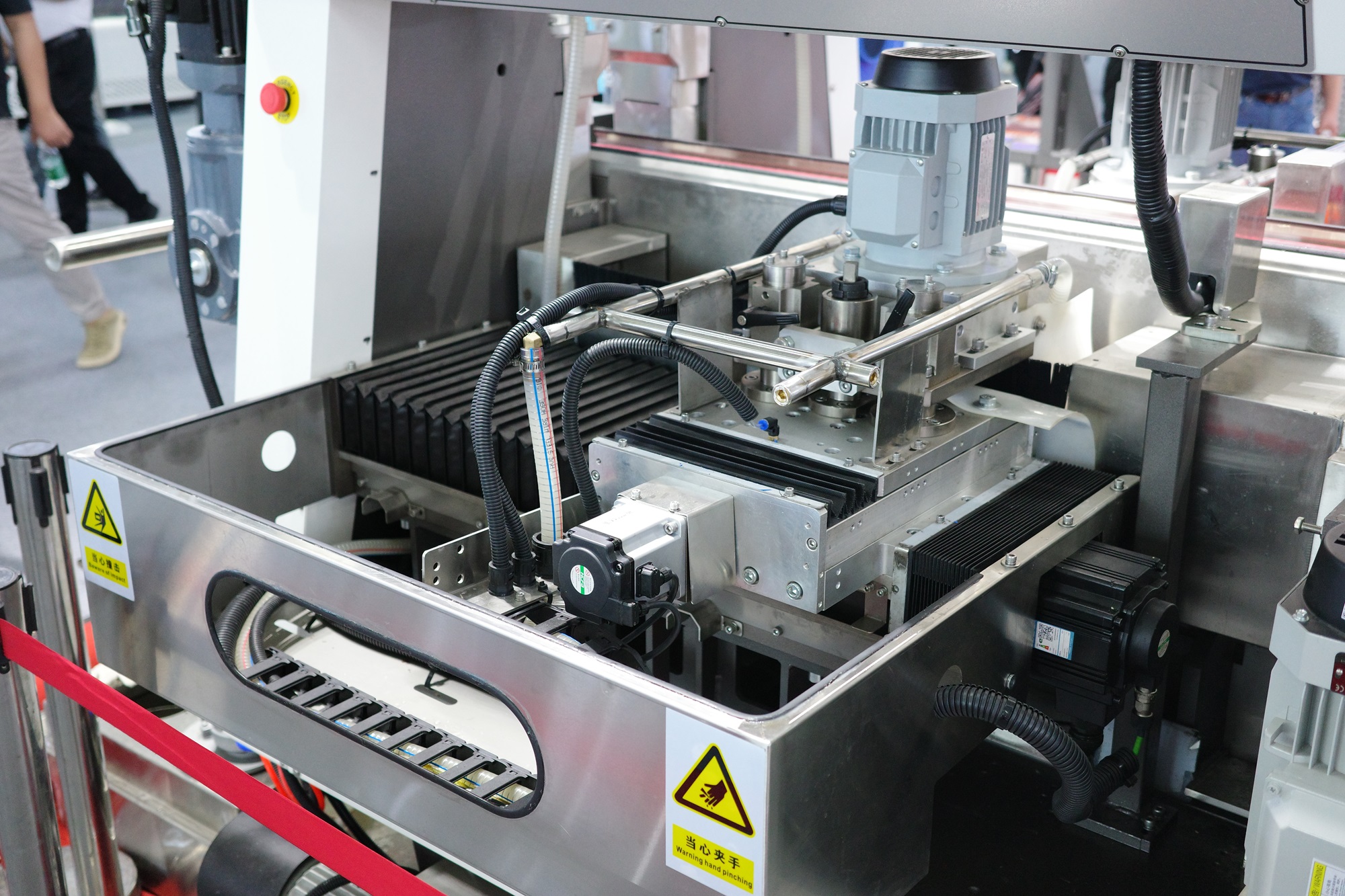

Enkongs' flagship glass edging machine solution – the fully automated SM24 Double Straight-Line Production Line – addressed three critical industry pain points:

Precision Beyond Convention

Adaptive diamond grinding heads maintained ≤0.1mm consistency across 3-25mm glass thicknesses

Real-time thickness compensation eliminated manual calibration for mixed batches

Integrated laser scanners verified edge geometry during operation, a first for commercial glass grinding machines

Intelligence Integrated

AI vision systems reduced job changeover from 45 minutes to under 7 minutes

Predictive maintenance algorithms alerted operators to wheel wear 48 hours pre-failure

Energy-recovery drives cut power consumption by 25% versus standard glass processing machines

Sustainable Engineering

Electrostatic dust collectors captured 99.2% particulate emissions

Modular design enabled 92% component refurbishment/reuse

Hydraulic-free operation eliminated 5,000 liters/year of oil waste per glass edging machine

3. Versatility Redefined: ZM9J Multi-Function Glass Grinding Machine

For specialty manufacturers processing curved shower doors, sculpted décor glass, or electronic cover glass, Enkongs' ZM9J glass grinding machine demonstrated unprecedented flexibility:

Configurable Precision

Nine interchangeable wheel stations handled rough grinding to optical polishing

Dynamic angle adjustment (0°-60°) accommodated complex bevels without secondary processing

Vibration-dampened spindles maintained micron-level accuracy on thin glass

A Shenzhen smartphone cover glass producer confirmed: "This glass processing machine eliminated three separate operations. We're achieving Ra 0.01μm finishes in single pass – something no other glass grinding equipment in its class delivers."

4. Global Validation: Glass Processing Machines for Tomorrow's Markets

Enkongs secured 47 letters of intent during the exhibition, with demand spanning continents and sectors:

| Sector | Application | Key Enkongs Solution |

|---|---|---|

| Automotive | Panoramic sunroof edges | SM24 glass edging machine |

| Architecture | High-rise curtain walls | ZM9J glass grinding machine |

| Electronics | Ultra-thin display covers | Customized glass processing machine |

| Art Glass | Sculptural installations | Multi-axis glass edging system |

Notably, 78% of buyers prioritized sustainability features – confirming Enkongs' strategic focus on green engineering for its glass processing machines.

5. Sustainable Innovation: The New Glass Grinding Machine Paradigm

Dr. Li Ming's keynote "Precision Without Planetary Cost" resonated deeply with policymakers and manufacturers:

"The next-generation glass grinding machine must achieve zero environmental compromise. Our solutions reduce energy consumption per polished meter by 30% while extending consumable lifecycles."

Enkongs' sustainability commitments materialized through:

Water Recycling Systems – Closed-loop filtration enabled 95% water reuse in glass processing machines

Renewable Integration – Power-regenerative drives fed excess energy back into facility grids

Circular Manufacturing – Remanufactured service kits extended equipment lifespans by 200%

These innovations align with China's Green Factory Grade A certification requirements taking effect in 2026.

6. Global Roadmap: Intelligent Glass Edging Machines Scale Worldwide

Post-exhibition, Enkongs accelerates its worldwide strategy:

Production Scale – Jiangmen factory expansion triples output of glass grinding machines by Q3 2026

Smart Technology – Partnership with Siemens embeds digital twins in all glass edging machine controls

Emerging Markets – Tropicalized glass processing machines debut at Glasstec 2025 for Southeast Asian clients

The Enkongs Difference: Where Vision Meets Precision

As the exhibition closed, one scene captured the industry's shift: A European engineer ran her finger along a freshly polished edge from Enkongs' glass edging machine, murmuring "I've never felt such consistency." Nearby, photovoltaic manufacturers debated AI optimization logs while sustainability officers scrutinized energy consumption reports.

The message echoed across the show floor: Tomorrow's glass landscape demands machinery that masters both micron-level precision and planetary responsibility. For global partners, Enkongs' glass grinding machines represent more than equipment – they are the foundation for transforming silica into revolutionary architecture, vehicles, and technologies.