In the demanding world of modern architecture, interior design, and specialized manufacturing, glass has transcended its traditional role. It’s no longer just a functional barrier; it’s a statement piece, a design element, and a critical component requiring flawless execution. Achieving the perfect edge – whether a crisp mitre, a soft pencil polish, or a complex bevel – is paramount. This is where advanced glass edging machine technology steps in, revolutionizing the capabilities of workshops and factories worldwide. Integrating a sophisticated glass grinding machine into your production line isn't merely an upgrade; it's a fundamental shift towards unparalleled quality, efficiency, and competitive advantage within the broader scope of glass processing machine solutions.

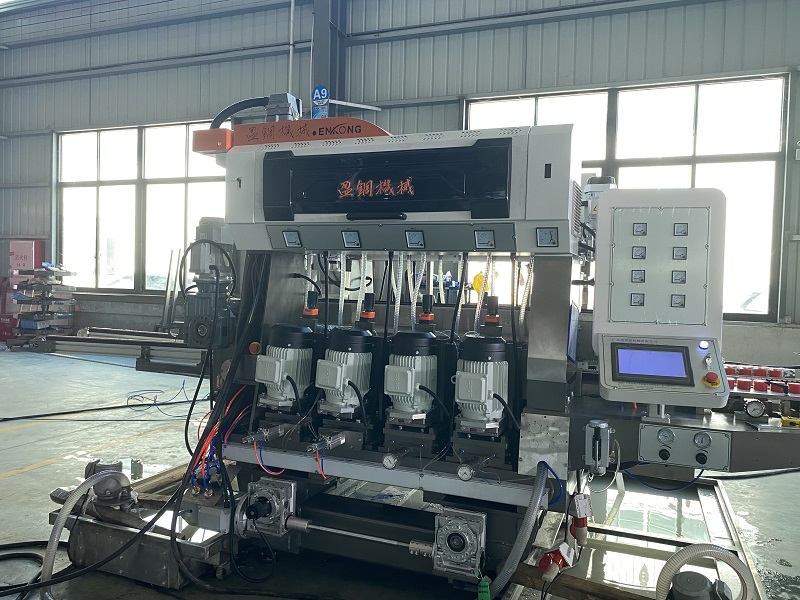

The core function of any high-performance glass edging machine is to transform rough-cut glass panels into precision-finished components. Manual grinding is inconsistent, labor-intensive, and struggles to meet the exacting tolerances demanded by today's markets. A dedicated glass grinding machine, however, automates this critical phase. Utilizing precisely calibrated diamond grinding wheels operating at controlled speeds and pressures, these systems remove material consistently and accurately along the entire edge profile. This automated precision is the bedrock of achieving optically perfect, chip-free edges repeatedly, batch after batch. The evolution of the glass grinding machine has been significant, moving from basic straight-line edgers to sophisticated CNC-controlled centers capable of complex shapes and intricate edge details with minimal operator intervention.

Integrating a robust glass edging machine significantly elevates your overall glass processing machine workflow. Think of it as the essential finishing touch within a comprehensive system. Glass arrives after cutting (often by waterjet or CNC cutting tables – other vital glass processing machine components) and before potential tempering, laminating, or coating. A high-quality glass grinding machine ensures that the edges are perfectly prepared for these subsequent processes. Poorly ground edges can lead to stress points during tempering or imperfections in laminated seals. Therefore, selecting the right glass edging machine isn't just about the edge itself; it's about ensuring the integrity and success of the entire downstream glass processing machine chain.

The versatility offered by modern glass grinding machine models is astounding. Beyond simple straight edges, contemporary glass edging machine units can produce a vast array of profiles:

Pencil Polish: A softly rounded edge, popular for safety and aesthetics.

Flat Polish (Diamond Polish): A crisp, 90-degree polished edge offering a clean, modern look.

Bevels: Angled edges, often used decoratively, ranging from simple chamfers to intricate multi-faceted designs.

Ogee & Other Decorative Profiles: Complex curved shapes adding significant aesthetic value.

Mitres: Precise 45-degree angles essential for seamless corner joints in frameless glass assemblies (e.g., shower enclosures, display cases).

This profile diversity, achievable consistently only with a capable glass grinding machine, directly translates to expanded market opportunities and the ability to tackle high-value projects requiring bespoke detailing. It transforms your glass processing machine capabilities from basic to boutique.

The operational advantages of deploying an automated glass edging machine are compelling:

Unmatched Consistency & Quality: Eliminates human error. Every edge, on every piece, matches the exact specification, delivering professional results that enhance brand reputation. The precision inherent in a good glass grinding machine is irreplaceable for high-end work.

Dramatically Increased Throughput: Automation drastically reduces processing time per piece compared to manual methods. A modern glass edging machine can process multiple edges simultaneously or handle larger panels efficiently, significantly boosting overall glass processing machine line output.

Reduced Labor Costs & Dependence: While skilled oversight is still needed, the heavy lifting (literally and figuratively) is done by the machine. This optimizes labor allocation and mitigates challenges in finding highly skilled manual polishers.

Enhanced Worker Safety: Automating the grinding process minimizes direct contact with sharp glass edges and rotating machinery, creating a safer workshop environment – a crucial consideration in any glass processing machine operation.

Minimized Material Waste: Precise control reduces over-grinding and breakage due to inconsistent manual pressure, leading to better material yield.

Superior Edge Clarity & Finish: Advanced grinding sequences and polishing capabilities within a high-end glass grinding machine produce optically superior edges free from haze, chips, or waviness – a hallmark of true quality.

For businesses looking to future-proof their operations, investing in a CNC (Computer Numerical Control) glass edging machine represents the pinnacle of glass processing machine technology. CNC systems offer:

Complex Shape Capability: Effortlessly process intricate curves and non-linear edges impossible with linear machines.

Precision Mitre Joints: Achieve perfect 45-degree angles consistently for invisible seams in high-end applications.

Programmable Profiles: Store countless edge profiles for instant recall, ensuring repeatability across jobs and reducing setup time.

Reduced Operator Skill Dependency: The machine follows the programmed path precisely, relying less on the operator's manual dexterity.

Integration Potential: CNC glass grinding machine units often integrate seamlessly with CAD/CAM software and other glass processing machine systems for a fully digital workflow.

Choosing the right glass edging machine is critical. Factors include the typical glass thicknesses processed, required edge profiles, desired throughput, available factory space, and budget. Reputable manufacturers offer solutions ranging from robust straight-line glass grinding machine models ideal for high-volume standard edges to sophisticated multi-axis CNC glass edging machine centers designed for complex architectural glass or artistic applications. Consider the machine's compatibility with your existing glass processing machine ecosystem – will it handle the sizes you cut? Can it feed directly into your tempering furnace line? Does it support the edge types your customers demand?

In an industry where aesthetics, safety, and precision are non-negotiable, the glass edging machine is far more than just a grinder; it's the cornerstone of quality edge finishing. Upgrading your capabilities with a modern, efficient glass grinding machine is an investment that delivers tangible returns: higher quality products, satisfied customers, increased production capacity, reduced operating costs, and a stronger competitive position. Don't let manual bottlenecks or inconsistent finishes limit your potential. Embrace the precision, efficiency, and versatility of advanced glass processing machine technology. Explore the transformative impact a state-of-the-art glass edging machine can have on your workflow, your product quality, and ultimately, your bottom line. Discover how the right glass grinding machine can unlock new levels of craftsmanship and productivity in your glass fabrication journey.