In the demanding world of high-quality glass fabrication, the edge isn't just a boundary—it's a signature. Achieving consistently flawless, safe, and visually stunning edges defines premium workmanship and separates industry leaders from the competition. Integrating a sophisticated glass edging machine into your workflow is no longer a luxury; it's the cornerstone of efficient, high-volume, and precision-focused production. This specialized glass processing machine technology transforms raw panels into refined masterpieces, handling everything from robust functional grinding to exquisite high-gloss polishing.

Manual methods, while sometimes necessary for unique one-offs, struggle with repeatability, speed, and achieving truly consistent premium finishes, especially across large batches. This is where the power of a dedicated glass grinding machine becomes indispensable. Modern automated systems handle the entire sequence – aggressive stock removal, precise profiling, fine grinding, and brilliant polishing – with unparalleled consistency and speed. A state-of-the-art glass edging machine significantly reduces cycle times while simultaneously elevating the quality benchmark for every single piece leaving your facility. This leap in capability directly translates to increased throughput, reduced labor costs, and the confidence to tackle complex, high-value projects.

Versatility is paramount for shops serving diverse markets. A well-engineered glass processing machine designed for edge work is remarkably adaptable. A single, robust glass grinding machine can be configured to expertly handle an astonishing array of materials: standard annealed float glass, toughened safety glass, delicate laminated panels, demanding low-iron glass for maximum clarity, and even textured or patterned varieties. Whether your primary output involves high-volume straight edges for architectural glazing, intricate bevels and shapes for luxury interiors, or specialized finishes for furniture and displays, a high-performance glass edging machine provides the essential flexibility. Investing in this core glass processing machine capability ensures your business remains agile and responsive to evolving client demands and market opportunities.

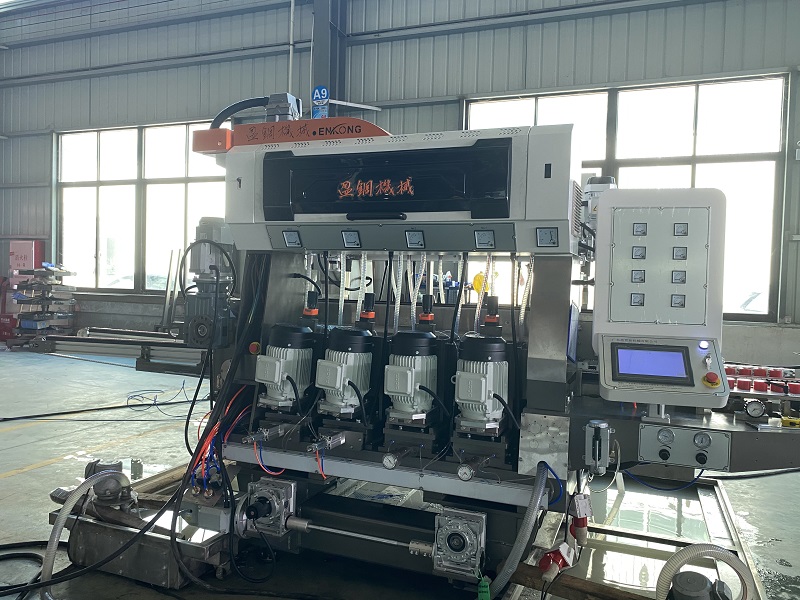

The technological core of this revolution lies in the advanced glass grinding machine. Contemporary units boast multiple, independently programmable spindles, each equipped with purpose-specific diamond abrasives. The process is meticulously orchestrated: powerful coarse grinding wheels rapidly shape the edge, followed by progressively finer grinding stages that refine the profile and prepare the surface. Operated via intuitive CNC interfaces, a modern glass edging machine allows operators to store countless edge profiles—from simple arrises to complex ogives and chamfers—ensuring perfect repeatability job after job. This automation minimizes human error and skill dependency.

Beyond speed and precision, a superior glass processing machine (glass edging machine) delivers profound operational benefits. Integrated water management systems are critical, providing continuous cooling and lubrication. Furthermore, the inherent consistency of a high-quality glass grinding machine drastically reduces material waste and costly rework caused by edge imperfections like chips, waves, or inconsistent finishes. This reliability is fundamental when working with high-value materials or meeting stringent quality control standards demanded by sectors like automotive, high-end architecture, or electronics. A dependable glass edging machine becomes the bedrock of your quality assurance process.

Selecting the optimal glass grinding machine requires a strategic assessment of your specific operational landscape. Key considerations include:

Glass Thickness Range: Can the glass grinding machine handle your typical stock, from thin 3mm substrates to thick 19mm+ laminated units or structural panels?

Edge Profile Complexity: Does your market demand simple straight edges, or do you need capabilities for bevels, miters, pencil edges, bullnoses, and complex curves?

Production Volume: Are you a boutique studio or a high-output manufacturer? Match glass processing machine throughput to your current and projected needs.

Automation Level: Consider options from semi-automatic straight-line edgers to fully automated CNC centers with loading/unloading systems.

Workspace Integration: Ensure the chosen glass processing machine fits physically and integrates smoothly with your existing cutting, washing, and tempering lines of glass edging machine.

Integrating a capable glass edging machine fundamentally reshapes your production dynamics. It transforms a traditionally labor-intensive, variable process into a streamlined, predictable, and highly efficient operation. The enhanced quality control inherent in automated glass grinding machine (glass processing machine) operation minimizes costly rejects and warranty claims. Ultimately, investing in a modern glass processing machine for edge finishing delivers a compelling return on investment through increased capacity, superior product quality, expanded service offerings, and a significantly strengthened competitive position in an exacting marketplace.

For discerning glass professionals committed to excellence, operational efficiency, and pushing the boundaries of what's possible with glass, embracing the advanced capabilities of today's glass grinding machine technology is a strategic imperative. It’s an investment in craftsmanship, productivity, and the future of your business. Explore the next generation of glass edging machine solutions and discover how this essential glass processing machine can unlock new levels of precision, versatility, and profitability within your operation. Elevate your craft from the edge inwards.